Method for controlling oil filling of clutches of automatic double-clutch gearbox

An automatic transmission and dual clutch technology, applied in clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve the problems of inability to accelerate, affecting the timeliness and smoothness of shifts, and adversely affecting the timeliness and smoothness of shifts. To achieve the effect of improving the smoothness of shifting, improving the timeliness and smoothness of shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

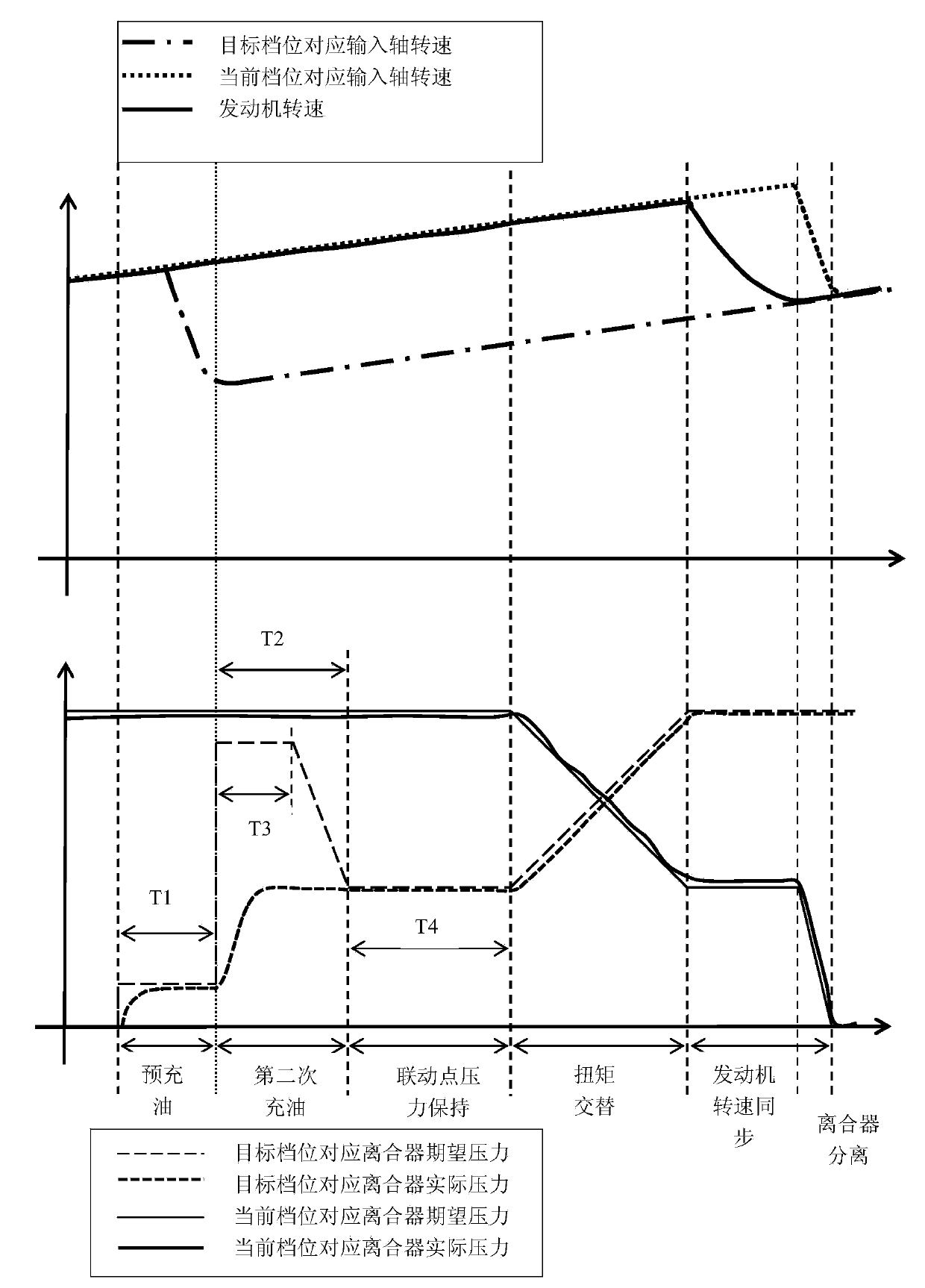

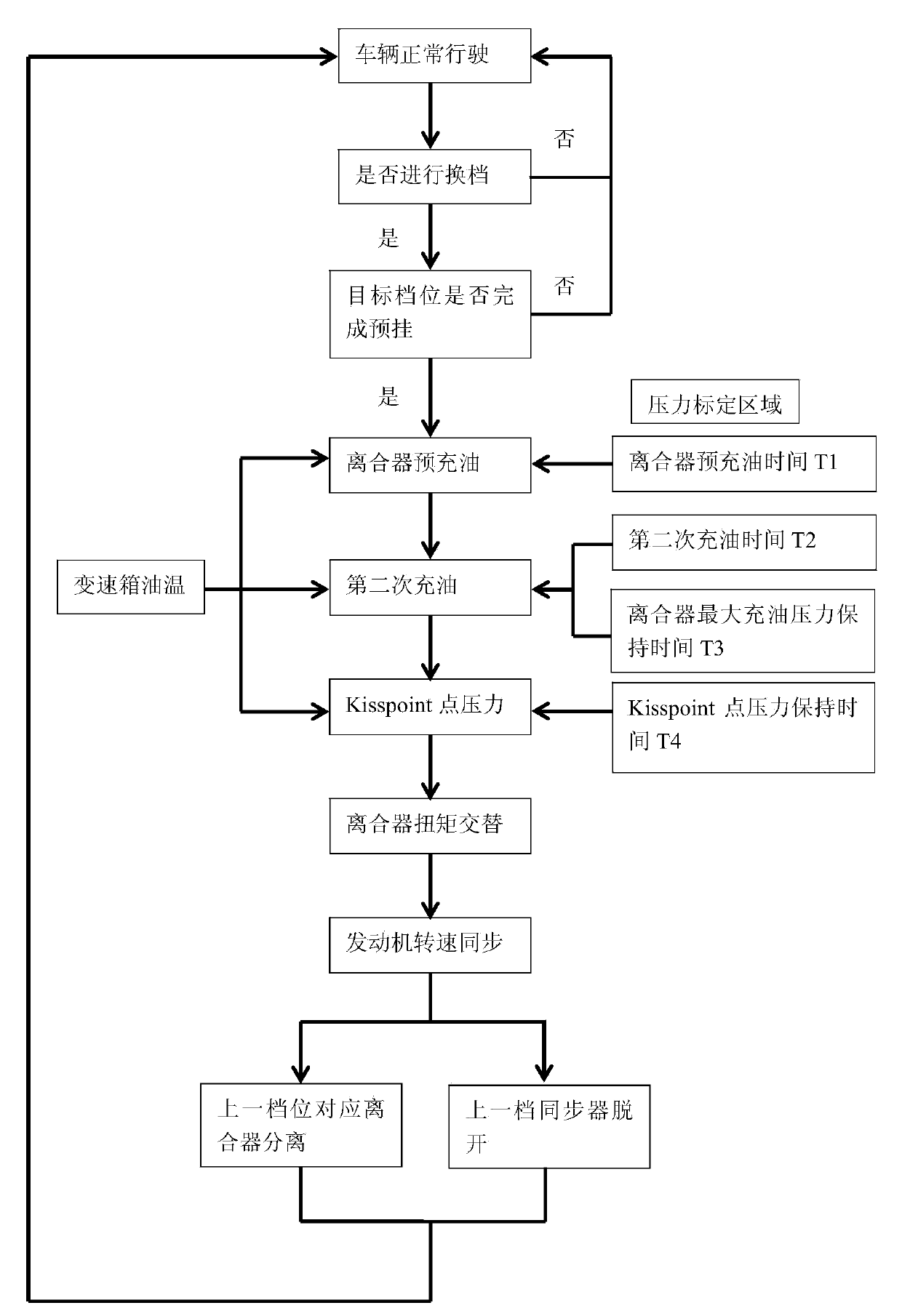

[0024] combine figure 1 , figure 2 . When the vehicle is running normally, the gearbox control unit will judge whether the vehicle needs to shift gears based on parameters such as the current engine throttle opening, vehicle speed, and vehicle operating mode. If the shift condition is satisfied, the transmission control unit selects the target gear according to the shift schedule of the vehicle in the current working mode, and performs pre-shifting. After the pre-engagement step is completed for the target gear, the clutch corresponding to the target gear is pre-charged with oil and kept for a predetermined time T1. In the pre-filling step, the actual pressure value of the clutch corresponding to the target gear should ideally reach the original calibrated expected pressure value and maintain it. The oil filling time T1 and the achieved pre-fill oil pressure are not the same as the original calibration value, which brings risks to the correct judgment and control of the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com