Construction method of architectural structure gypsum board with paper surface hung ceiling

A paper-faced gypsum board and construction method technology, applied in building components, building structures, buildings, etc., can solve problems such as easy cracks, unsightly appearance, easy deformation, etc., to achieve clear edges, simple construction method steps, and mission long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

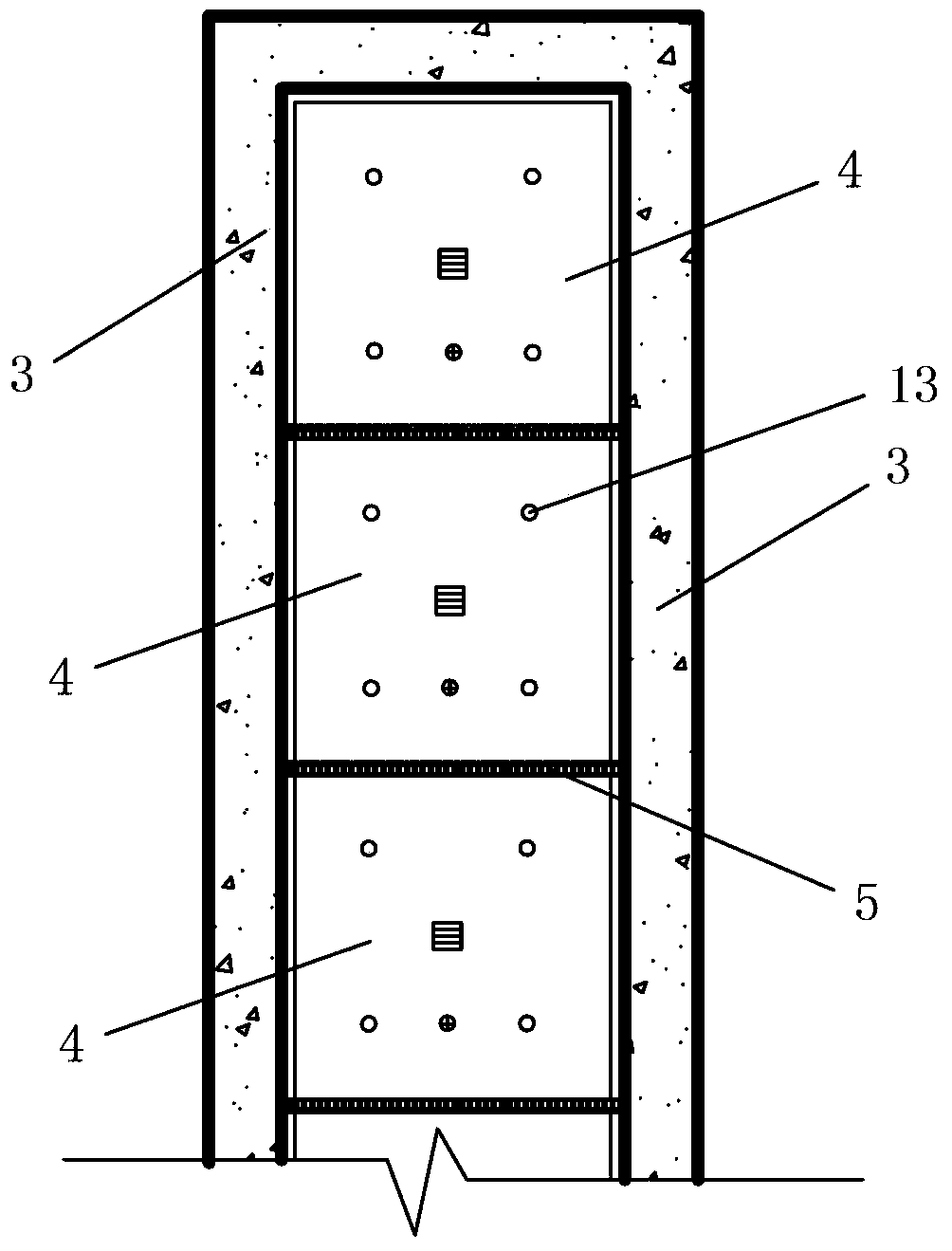

[0042] In this example, if figure 1 Shown is a construction method for a suspended ceiling of a building structure with plasterboard, comprising the following steps:

[0043] Step 1. Light steel keel installation: combine image 3 , install a light steel keel 1 under the roof of the building that needs to be suspended, the light steel keel 1 is arranged horizontally and it is hung on the building roof by a plurality of hanging parts 2 .

[0044] Step 2, installation of overlay gypsum board: install overlay gypsum board on the light steel keel 1 installed in step 1, and the overlay gypsum board is fixedly installed on the light steel keel 1 through a plurality of fasteners. See figure 2 .

[0045] The shape of the overlay gypsum board is rectangular, and a gap of 15 mm to 20 mm is left between the surrounding side walls of the overcoat gypsum board and the wall 3 , and the surrounding side walls of the overcoat gypsum board and the wall 3 The gap between them is the side s...

Embodiment 2

[0078] In this example, if Figure 7 As shown, the difference from Example 1 is that the width of the overlay gypsum board in step one and step two is greater than 5m, and the overlay gypsum board is provided with a longitudinal deformation seam 9, and the number of the longitudinal deformation seam 9 is It is one or more lines, and the multiple longitudinal deformation joints 9 are arranged from left to right along the width direction of the overlay gypsum board. Square gypsum board 1 is divided into multiple square gypsum boards 2 through multiple longitudinal deformation joints 9, and each of the light steel dragon skeletons is divided into multiple light steel dragon skeletons with multiple longitudinal deformation joints 9 as boundaries. Skeleton segments, the two adjacent light steel dragon skeleton segments on the left and right are disconnected from each other, and the plurality of square gypsum boards are respectively arranged directly under the plurality of light ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com