Building decorative stone panel fixing device and construction method

A fixing device and building technology, applied in building construction, building material processing, construction, etc., can solve problems such as stone falling off, nut installation and fastening is difficult to grasp, bolt and nut installation is not fast enough, etc., to achieve safe and firm disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

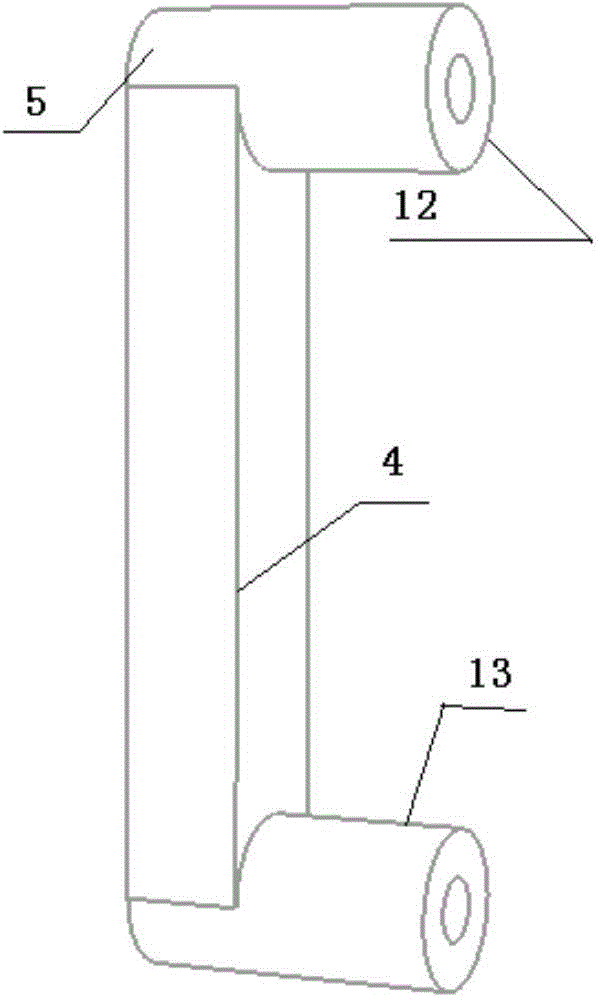

[0048] Such as figure 1 As shown, both the first hanging joint and the second hanging joint are threaded pipes, and the connecting head 5 is a threaded joint, which is coaxially connected with the first hanging joint 12 to form a whole. During installation, screw the connecting head 5 into the bolt preset on the wall, adjust the distance between the fixing device and the wall through the depth of the connecting head 5 screwed into the bolt, and then hang a stone panel with a matching notch on it. Insert the first hanging joint 12, and then hang another stone panel with a matching notch into the second hanging joint 13. It is also possible to hang the same stone panel into the first hanging joint and the second hanging joint of the fixing device at the same time. Before hanging, adhesive or structural glue can be injected into the notch of the stone panel first to enhance the stability.

Embodiment 2

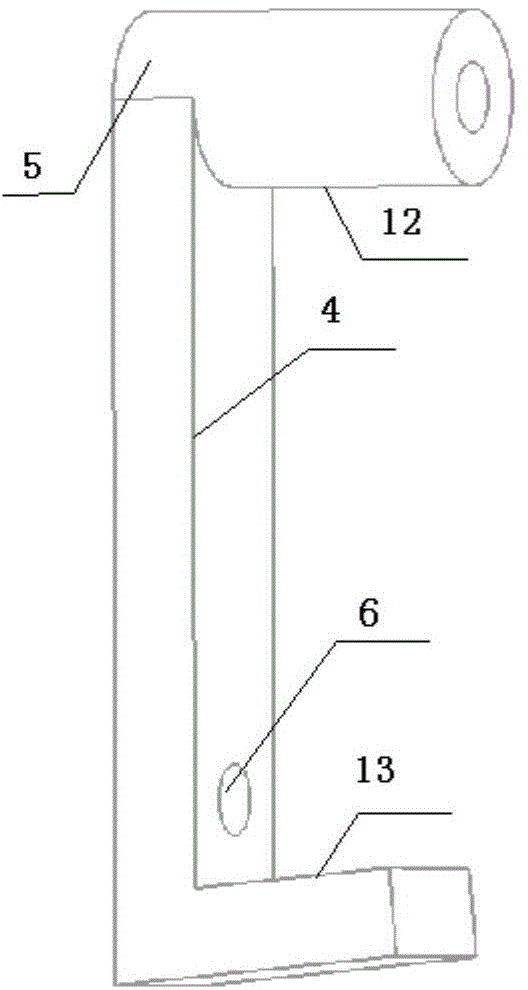

[0050] Such as figure 2 As shown, the first hanging joint is a threaded pipe, the second hanging joint is a straight rod inclined upward at an angle with the longitudinal axis of the hanging plate 4, and the connecting head 5 is a threaded joint, which is connected with the first hanging joint 12 as a whole. An abutting adjustment hole 6 is also provided. When installing, screw the connector 5 into the bolt preset on the wall, and adjust the distance between the fixing device and the wall by passing the screw against the adjustment hole 6, according to the distance requirements between the fixing device and the wall To determine the depth of the screw inserted into the wall, to ensure that the mounting plate of the fixing device is in a state level with the wall, to avoid the skewing of the fixing device, and then hang a stone panel with a matching notch into the first hanging joint 12 , and then another stone panel with a supporting notch is hung into the second joint 13. ...

Embodiment 3

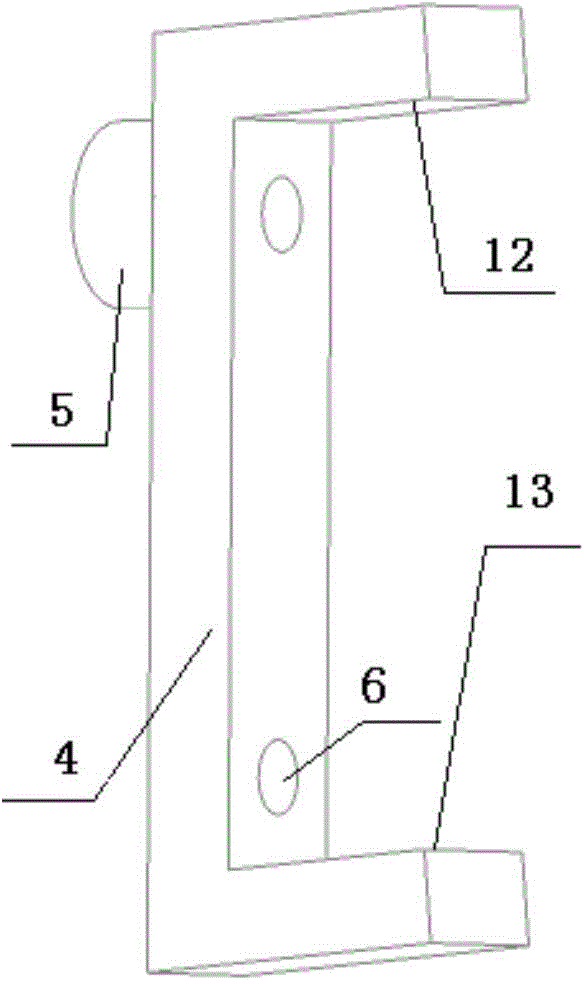

[0052] Such as image 3 As shown, the present invention is a fixing device in which the first hanging joint is a straight rod inclined upward at an included angle with the axis of the connecting head 5, and the second hanging joint is a straight bar inclined upward at an included angle with the longitudinal axis of the joint plate 4. The head 5 is a threaded joint, which is arranged on the bottom of the hitch plate 4 against the adjustment hole 6 . The specific method of installation and use is the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com