Method for fermentation production of succinic acid by using cotton fiber material to fix actinobacillus succinogenes

An actinomycetes, cotton fiber technology, applied in microorganism-based methods, biochemical equipment and methods, fixed on/in organic carriers, etc., can solve the problem of high production cost, prolonged, low bacterial biomass, etc. problem, to achieve the effect of high acid yield, high conversion rate and high production intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

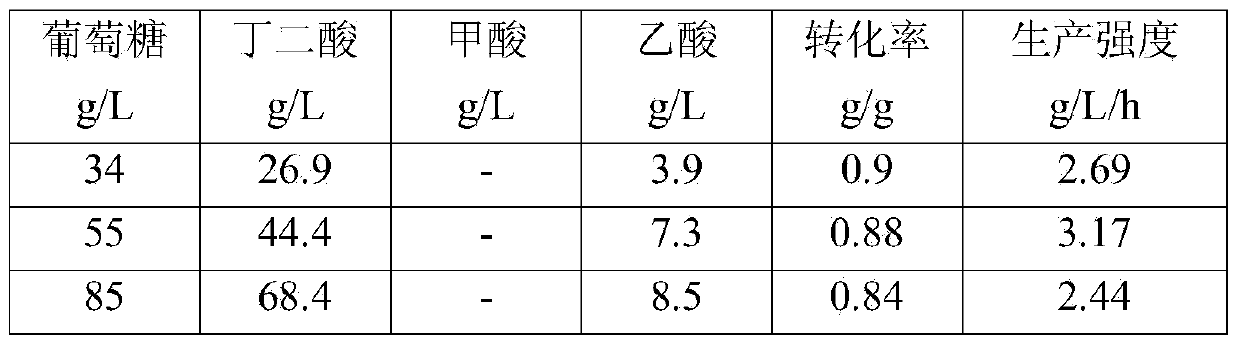

[0022] Embodiment 1 batch fermentation

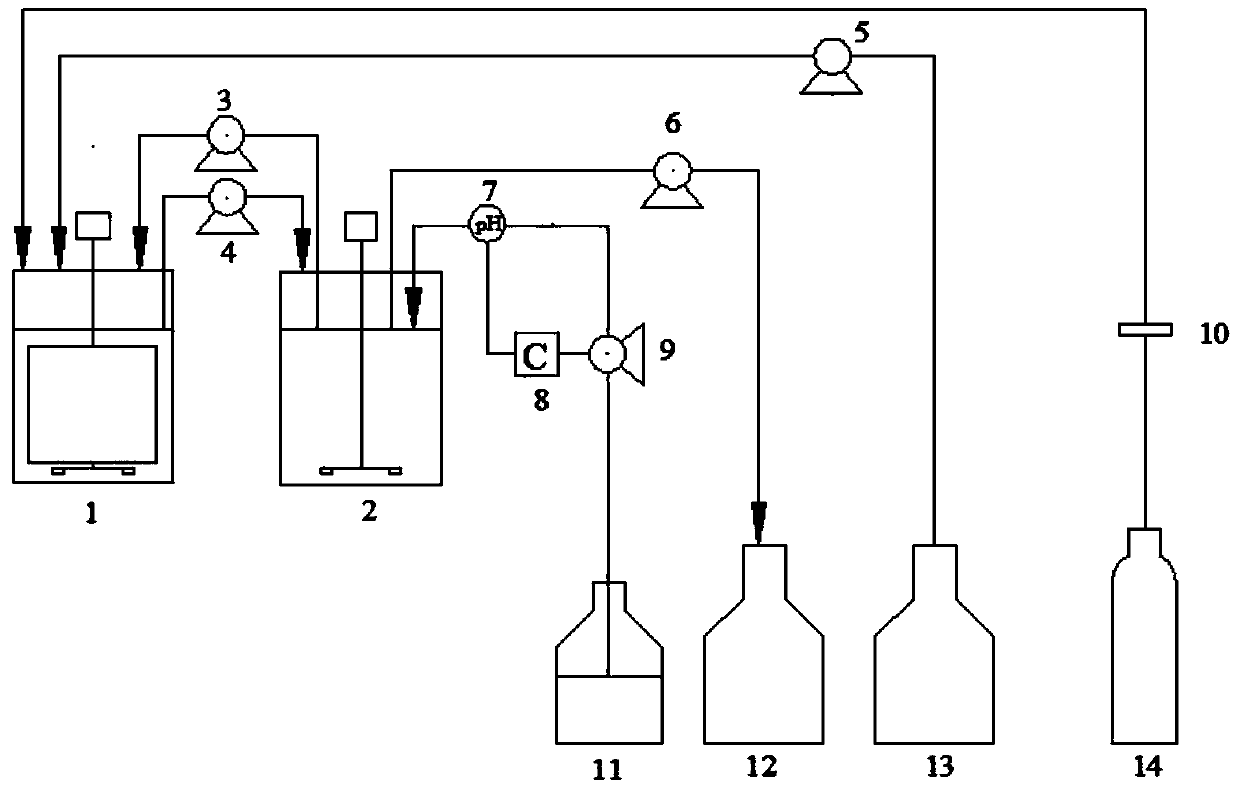

[0023] In the 3L fermenter fiber bed reactor device: Take the fiber bed carrier (the thickness of the fabric is 1mm, the porosity > 95%), and the surface area is 60×6cm 2 , wind it on the stirring shaft of the fermenter, fix the top with a stirring paddle, and fix it with stainless steel wire mesh. The diameter of the wire mesh is about 2.5×2.5cm 2 , and does not affect stirring. The diameter of the fiber bed is about 11cm, the height is 16cm, 115-121°C for 20 minutes, and then 121°C for 20 minutes after overnight;

[0024] The seeds of A. succinogenes CCTCC NO:M2012036 were cultured statically in an anaerobic incubator for 12 hours at a temperature of 38°C. Put the seed medium into the fiber bed reactor, add the seeds of Actinobacillus succinicum shake flask according to the inoculum amount of 2.5%, and incubate at 38°C under the flow of N 2 with CO 2 Under the anaerobic condition of the mixed gas, the adsorption was cultivated for...

Embodiment 2

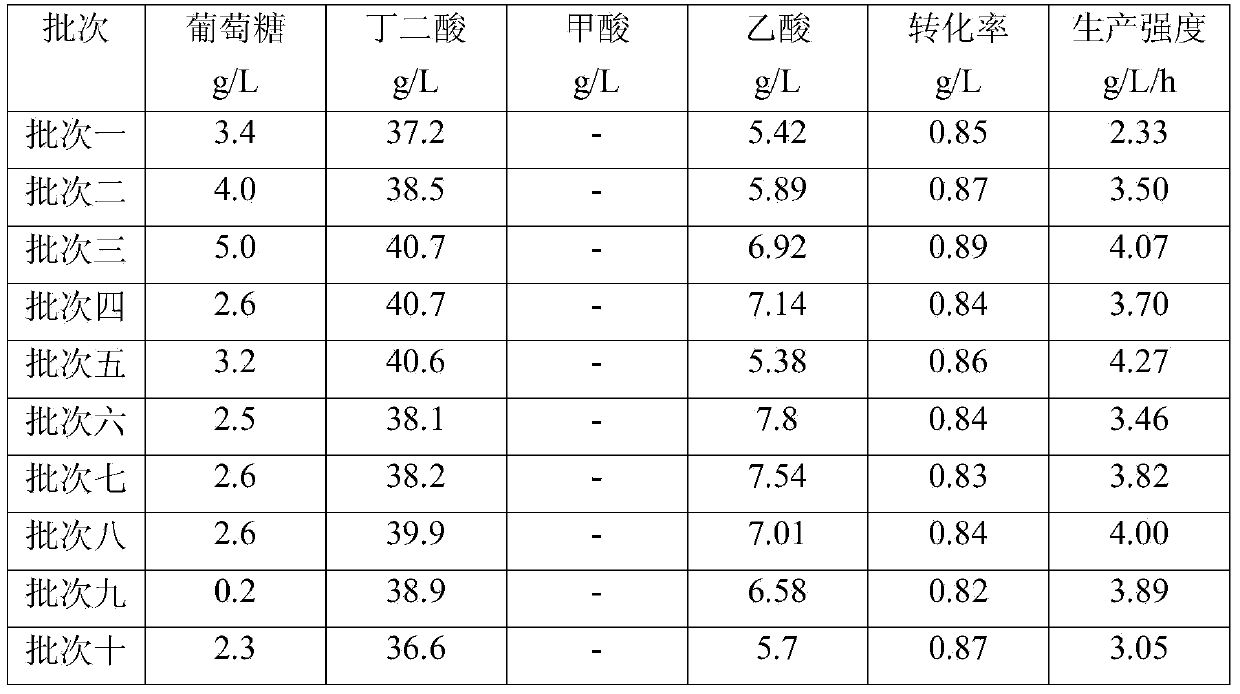

[0028] Embodiment 2 Batch fermentation repeatedly

[0029] Referring to the method of Example 1, the adsorbed Actinobacillus succinici was cultivated in a 3L fiber bed reactor for repeated batch fermentation. The initial sugar concentration of the fermentation medium was 50g / L glucose, and samples were taken every 3-4 hours to measure the acid production. After an average of 12 hours of fermentation, the glucose concentration dropped to 3g / L. The fresh medium was replaced, and 10 batches of batch fermentation were repeated. The results are shown in Table 2. After the end of the 10th batch, no cell growth was found to stop, which indicated that the fiber bed reactor could still be used.

[0030] Table 2 Fiber bed reactor immobilized repeated batch fermentation to produce succinic acid

[0031]

Embodiment 3

[0032] Embodiment 3 Fed-batch fermentation

[0033] Referring to the method of Example 1, the 3L fiber bed reactor was cultivated in the fiber bed reactor. Actinobacillus succinicum was cultivated, and fed-batch fermentation was carried out in order to obtain a high concentration of succinic acid. The initial glucose of the fermentation medium was 60g / L, and when the residual sugar decreased to 12.4g / L in the first 12 hours of the fermentation process, the glucose concentration was added to 67g / L; after 38 hours, the residual sugar decreased to 5g / L, and the concentration of succinic acid was 87g / L, the conversion rate is 0.83g / g, and the production intensity is 2.38g / L / h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com