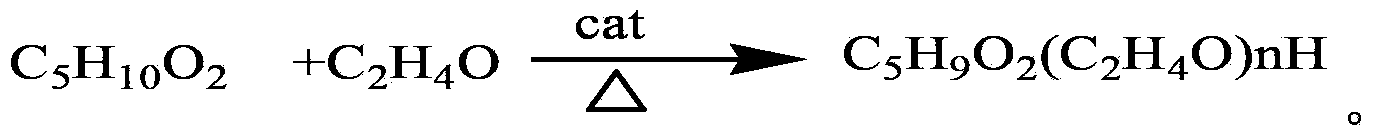

Synthesis method of tetrahydrofurfuryl alcohol polyoxyethylene ether

A technology of polyoxyethylene ether and tetrahydrofurfuryl alcohol, which is applied in the field of synthesis of tetrahydrofurfuryl alcohol polyoxyethylene ether, can solve the problems that have not been reported in the literature, and achieve the effects of reasonable product distribution, light color and improved selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

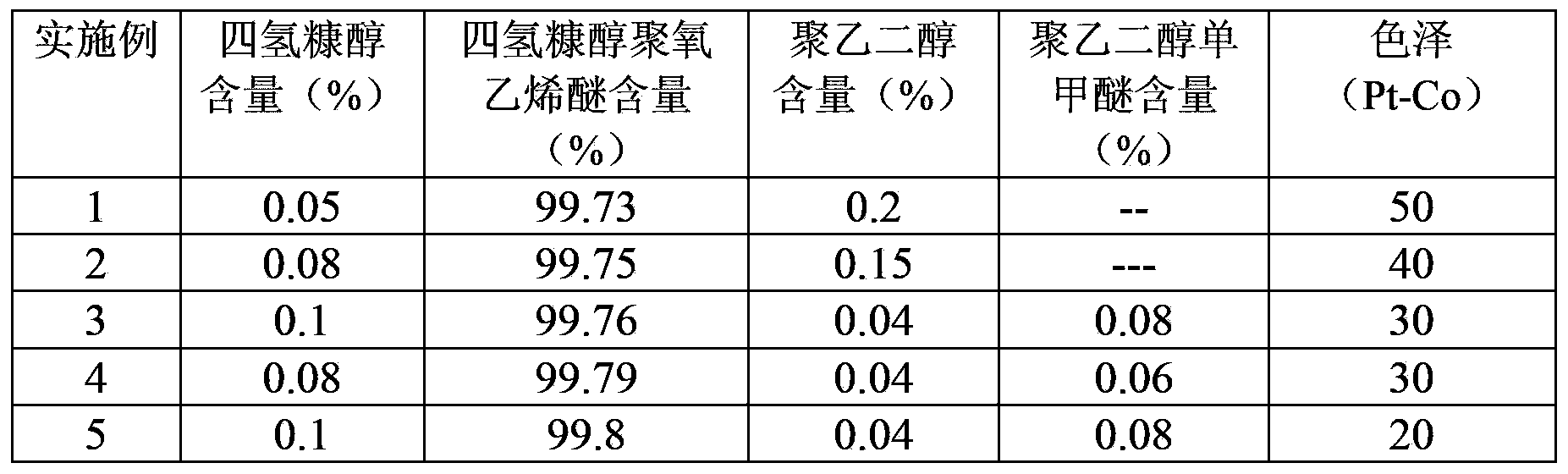

Examples

Embodiment 1

[0015] In this example 1) Add 102g of tetrahydrofurfuryl alcohol, 2.0g of solid potassium hydroxide, 50g of acetone, (the weight ratio of acetone:tetrahydrofurfuryl alcohol = 1:2.04) vacuum with a vacuum pump, using N 2 Replace the air in the reactor. After three replacements, the temperature is raised to 58℃ under vacuum ≥-0.02MPa to start collecting the distilled liquid (the vacuum pipe is connected to the condenser to recover the distilled liquid), and the dehydration temperature is 70℃. The collected liquid is tested , After the water is evaporated ≥ 0.64g, stop vacuuming and close the vacuum valve; 2) Start adding ethylene oxide continuously, control the reaction temperature at 60-80℃, the pressure in the reactor at 0.1-0.55Mpa, add epoxy in total 880 g of ethane (the molar ratio of tetrahydrofurfuryl alcohol: ethylene oxide: catalyst = 1:20:0.04). After the addition is completed, keep holding the reaction until the pressure no longer drops. After the reaction is completed...

Embodiment 2

[0018] In this embodiment 1) Add 102g of tetrahydrofurfuryl alcohol, 3.0g of solid sodium hydroxide, and 100g of acetone (weight ratio of acetone: tetrahydrofurfuryl alcohol = 1:1.02) into the reaction kettle; vacuum with a vacuum pump, using N 2 Replace the air in the reactor, replace it three times, heat up to 58℃ under vacuum ≥-0.02MPa and start collecting the steamed liquid (the vacuum pipe is connected to the condenser to recover the steamed liquid), the dehydration temperature is 100℃, the collected liquid is tested , After the water is evaporated ≥1.0g, stop vacuuming and close the vacuum valve; 2) Start adding ethylene oxide continuously, control the reaction temperature at 60-80℃, the pressure in the reactor at 0.1-0.55Mpa, add epoxy in total 440 g of ethane (the molar ratio of tetrahydrofurfuryl alcohol:ethylene oxide:catalyst=1:10:0.07). After the addition is completed, keep holding the reaction until the pressure no longer drops. After the reaction is completed, the...

Embodiment 3

[0021] Add 204g of tetrahydrofurfuryl alcohol, 2.5g of solid potassium methoxide, 20.4g of acetone (weight ratio of acetone:tetrahydrofurfuryl alcohol = 1:10) into the reaction kettle, vacuum with a vacuum pump, and use N 2 Replace the air in the reactor. After three replacements, the temperature is raised to 58°C under vacuum ≥-0.02MPa to start collecting the distilled liquid (the vacuum pipe is connected to the condenser to recover the distilled liquid), and the dealcoholization temperature is 58°C. It was detected that after methanol was distilled out of ≥1.0g, stop vacuuming, close the vacuum valve, and start adding ethylene oxide continuously, control the reaction temperature at 60-80℃, the pressure in the reactor at 0.1-0.55Mpa, and add ethylene oxide in total 352 g of alkanes (molar ratio of tetrahydrofurfuryl alcohol:ethylene oxide:catalyst=1:4.0:0.02). After the addition is completed, keep holding the temperature and continue to react until the pressure no longer drops....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com