Compound expanding agent for inhibiting temperature rising in early stage and promoting hydration in later stage and preparation method thereof

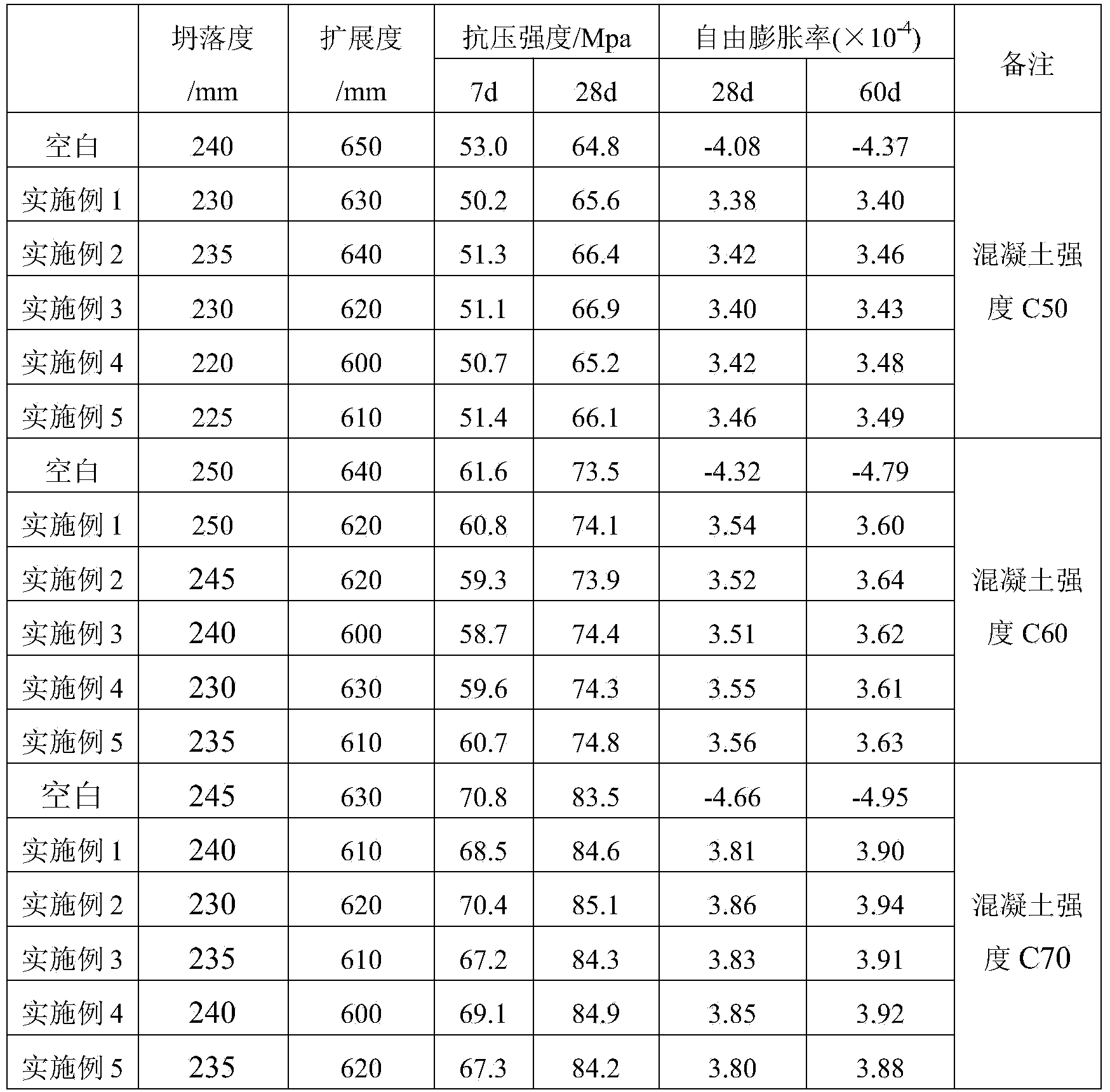

A composite expansion agent and temperature rise technology, applied in the field of building materials, can solve problems such as low water-to-binder ratio, large hydration temperature rise, temperature cracks, etc., achieving good environmental compatibility, sustainable expansion and long-term compensation, drying shrinkage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

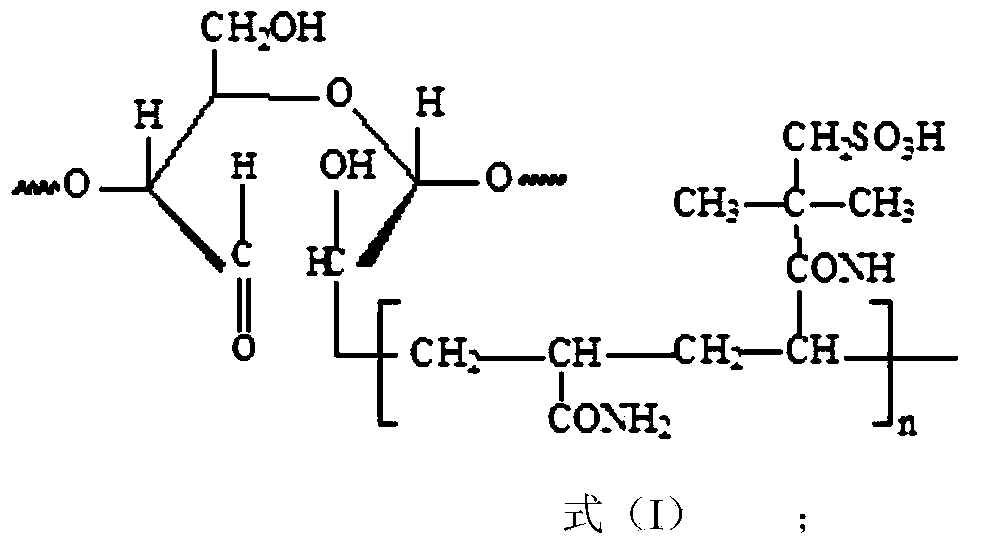

[0034] A composite expansion agent that suppresses temperature rise in the early stage and promotes hydration in the later stage, the preparation process of which comprises the following steps:

[0035] (1) Weigh each component: calcium oxide, sulphoaluminate cement clinker, anhydrite, magnesium oxide, boric acid, zinc sulfate, and ICA, the mass percentage of each component is shown in Table 1 below; (2) Calcium oxide , sulphoaluminate cement clinker and anhydrite are mixed and ground to a specific surface area ≥ 280m 2 / kg; (3) Separately grind magnesium oxide to a specific surface area ≥ 450m 2 / kg; (4) Mix and homogenize the materials obtained in step 2) and step 3) with other materials remaining in step 1) to obtain the composite expansion agent, and pack it for storage.

[0036] The calcium oxide is light-burned calcium oxide, which is calcite calcite after being crushed and calcined at a high temperature of 900-1100°C;

[0037] The sulphoaluminate cement clinker is mad...

Embodiment 4

[0051] In Example 4, the preparation method of the ICA is roughly the same as that of Examples 1-3, the difference being: (1) The mass of cassava starch weighed is 1 g; (2) The weighed ammonium cerium nitrate and ammonium persulfate (3) The mass of the monomer acrylamide weighed is 0.1g, the mass of bismethacrylamide is 0.01g, the temperature of the graft copolymerization reaction is 50°C, and the dropping time of the monomer solution (4) The mass ratio of 2-acrylamide-2-methylpropanesulfonic acid to monomer acrylamide is 1:1, the stirring speed of composite crosslinking is 80r / min, and the reaction temperature is 50°C. The time is 2.5h; (5) Hydrolysis: adjust the pH value to 10.

Embodiment 5

[0052] In Example 5, the preparation method of the ICA is roughly the same as that of Examples 1-3, the difference being: (1) the mass of tapioca starch weighed is 4g; (2) the weighed ammonium cerium nitrate and ammonium persulfate (3) The mass of the monomer acrylamide weighed is 10g, the mass of bismethacrylamide is 0.05g, the temperature of the graft copolymerization reaction is 80°C, and the dropping time of the monomer solution is 0.7h; (4) The mass ratio of 2-acrylamide-2-methylpropanesulfonic acid to monomer acrylamide is 1:9, the stirring speed of composite crosslinking is 90r / min, the reaction temperature is 80℃, and the reaction time (5) Hydrolysis: adjust the pH value to 11.

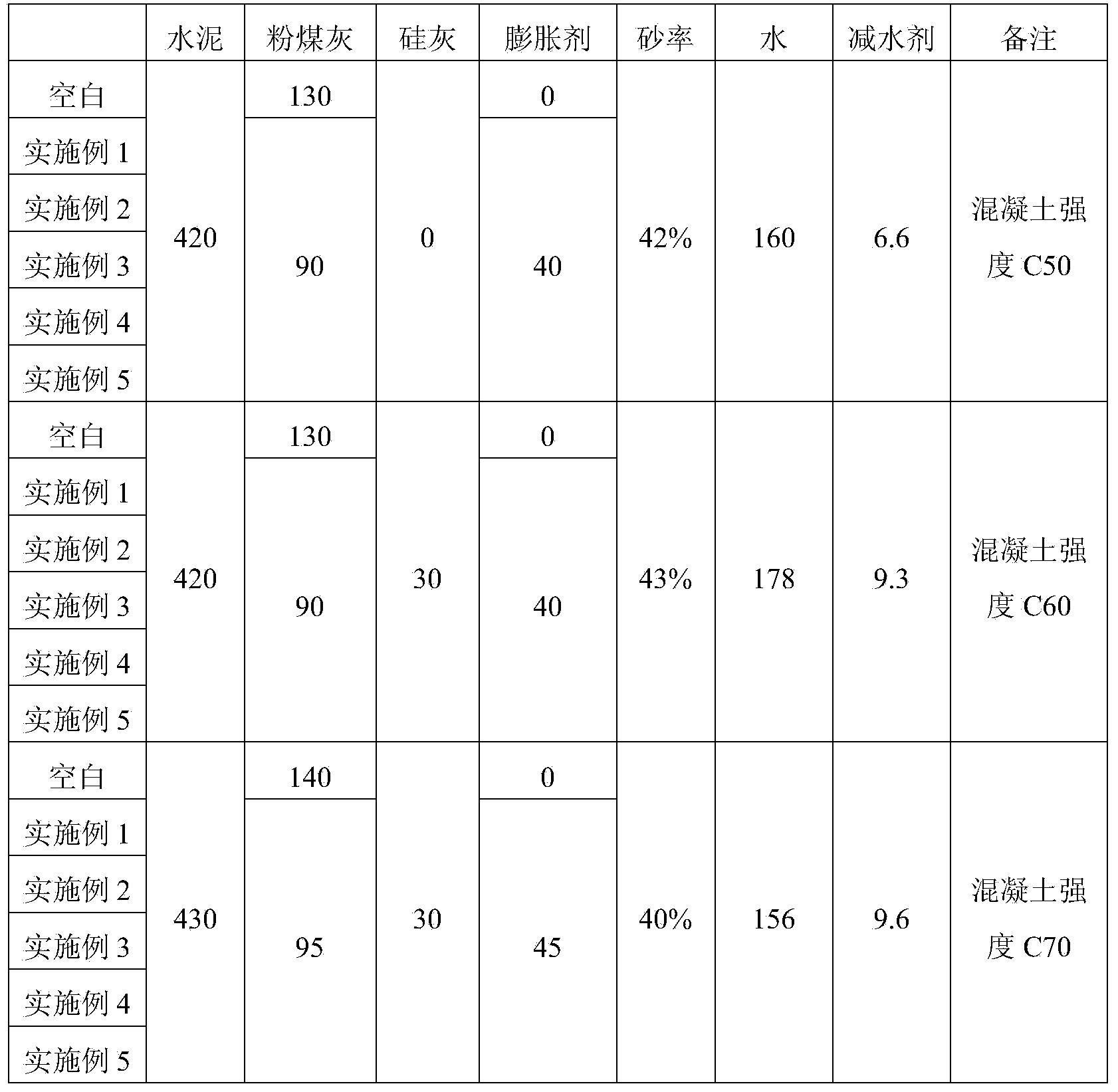

[0053] Table 1 The percentage of each component of the composite expansion agent (%)

[0054] Example

Sulphoaluminate cement clinker

MgO

ICA

1

10

43

35

10

0.3

1.5

0.2

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com