Preparation method of high-gloss catalytic-activity bismuth oxyiodide crystal

A technology of bismuth oxyiodate and catalytic activity, which is applied in chemical instruments and methods, crystal growth, halogen oxides/oxyacids, etc., can solve the problems of complex preparation of composite materials, high cost of precious metals, poor stability, etc., and achieve synthesis The method and experimental steps are simple, the preparation yield is high, and the effect of high photogenerated electron and hole separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Measure 80mL of deionized water and add it to the beaker, weigh 0.485g of bismuth nitrate pentahydrate and add it to the above solution, stir continuously so that the bismuth nitrate is fully dispersed in the water, hydrolyze to generate bismuth oxynitrate, and form a uniform suspension. 0.214g of potassium iodate was added to the above solution, and stirred continuously to form a uniform milky white solution. Put the mixture into a 100mL autoclave lined with polytetrafluoroethylene, react at 150°C for 5 hours, cool to room temperature naturally, separate the sample by suction filtration, and wash the sample with deionized water and ethanol pentahydrate respectively 3 times and dried to obtain the product bismuth oxyiodate crystals.

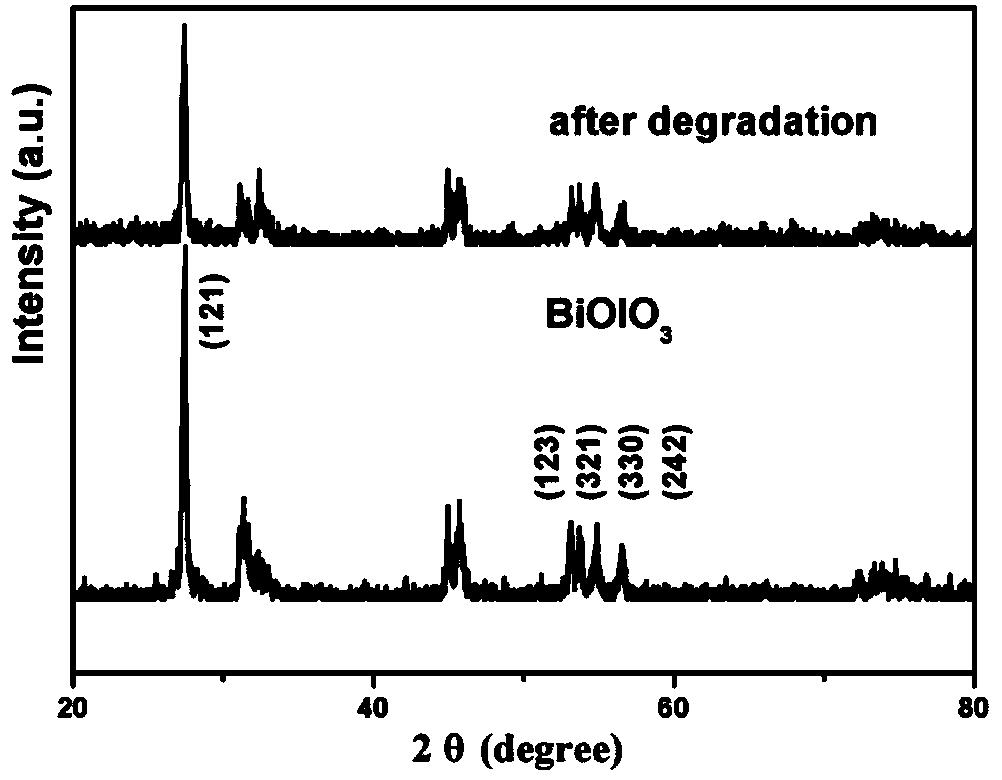

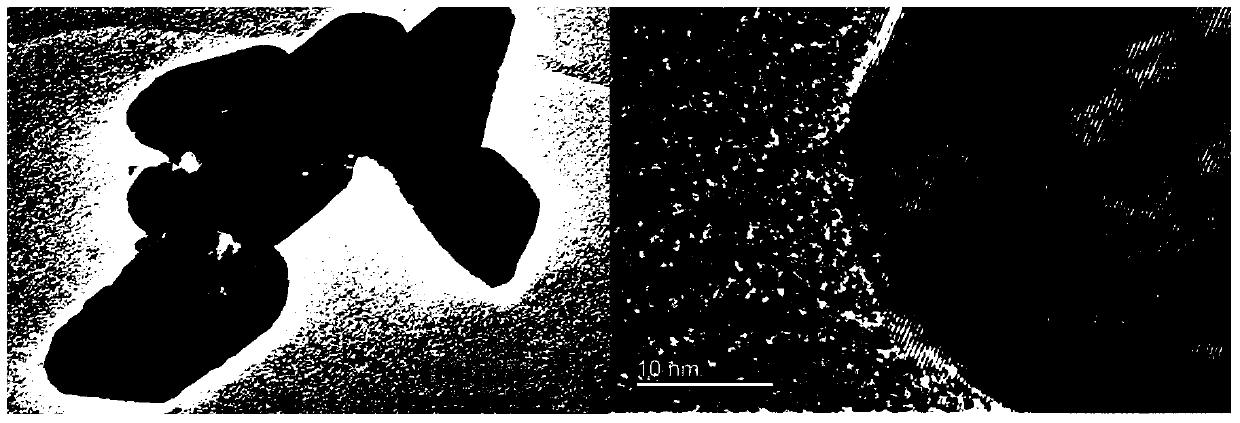

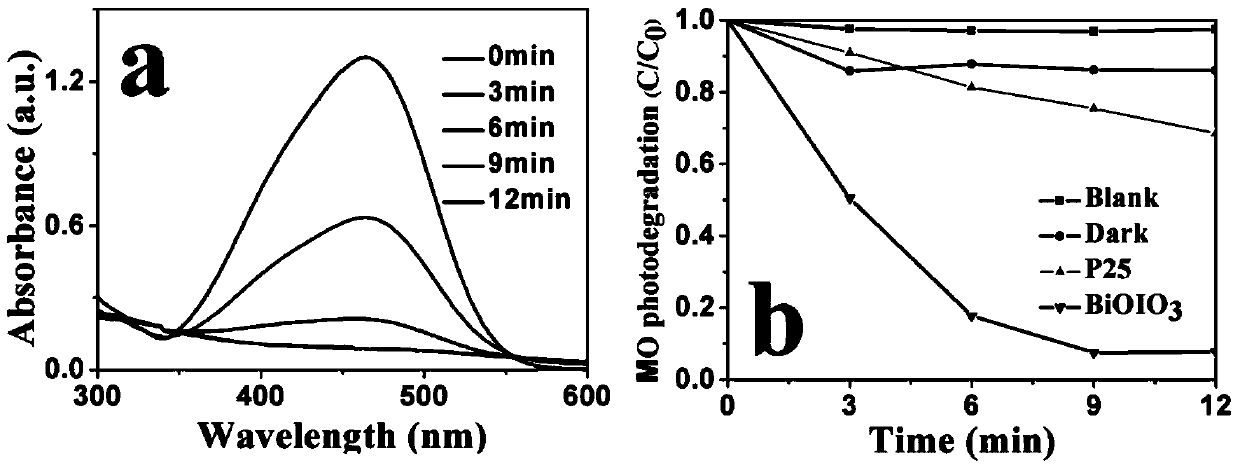

[0028] attached figure 1 (Black) is the X-ray diffraction pattern of the product obtained in this example. It can be seen from the figure that each diffraction peak of the product is bismuth oxyiodate in the orthorhombic phase, and there ...

Embodiment 2

[0031] Measure 80mL of deionized water and add it to the beaker, weigh 0.485g of bismuth nitrate pentahydrate and add it to the above solution, stir constantly so that the bismuth nitrate is fully dispersed in the water, hydrolyze to generate bismuth oxynitrate, and form a uniform suspension. 0.214g of potassium iodate was added to the above solution, and stirred continuously to form a uniform milky white solution. Put the mixture into a 100mL autoclave with a polytetrafluoroethylene liner, react at 160°C for 5 hours, cool to room temperature naturally, separate the sample by suction filtration, and wash the sample with deionized water and ethanol pentahydrate respectively 3 times, dry.

[0032] attached Figure 5 It is the X-ray diffraction pattern of the product obtained in this embodiment, and it is known from the figure that the product is a pure-phase cubic phase bismuth oxyiodate crystal. attached Figure 6 It is the SEM image of the product obtained in this example, ...

Embodiment 3

[0034] Measure 80mL of deionized water and add it to the beaker, weigh 0.485g of bismuth nitrate pentahydrate and add it to the above solution, stir constantly so that the bismuth nitrate is fully dispersed in the water, hydrolyze to generate bismuth oxynitrate, and form a uniform suspension. 0.214g of potassium iodate was added to the above solution, and stirred continuously to form a uniform milky white solution. Put the mixture into a 100mL autoclave with a Teflon liner, react at 150°C for 12 hours, cool to room temperature naturally, separate the sample by suction filtration, and wash the sample with deionized water and ethanol pentahydrate respectively 3 times, dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com