Transferring vehicle of engine hoods of automobile

A technology of automobile engine and turnover cart, which is applied to trolleys, motor vehicles, multi-axle trolleys, etc., can solve the problems of storage, inconvenient turnover, affecting product qualification rate, low work efficiency, etc., and achieves simple structure, neat storage, and space saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments.

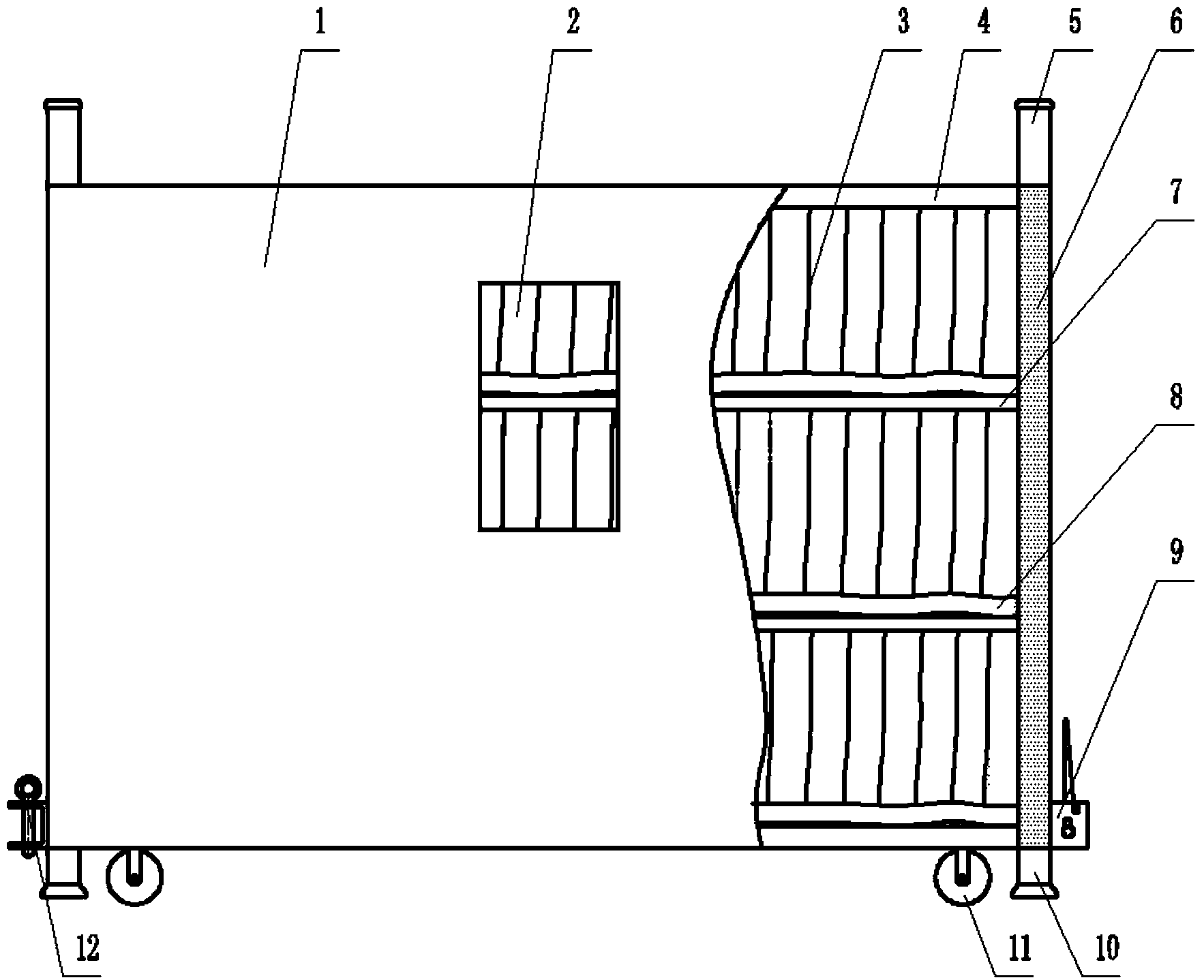

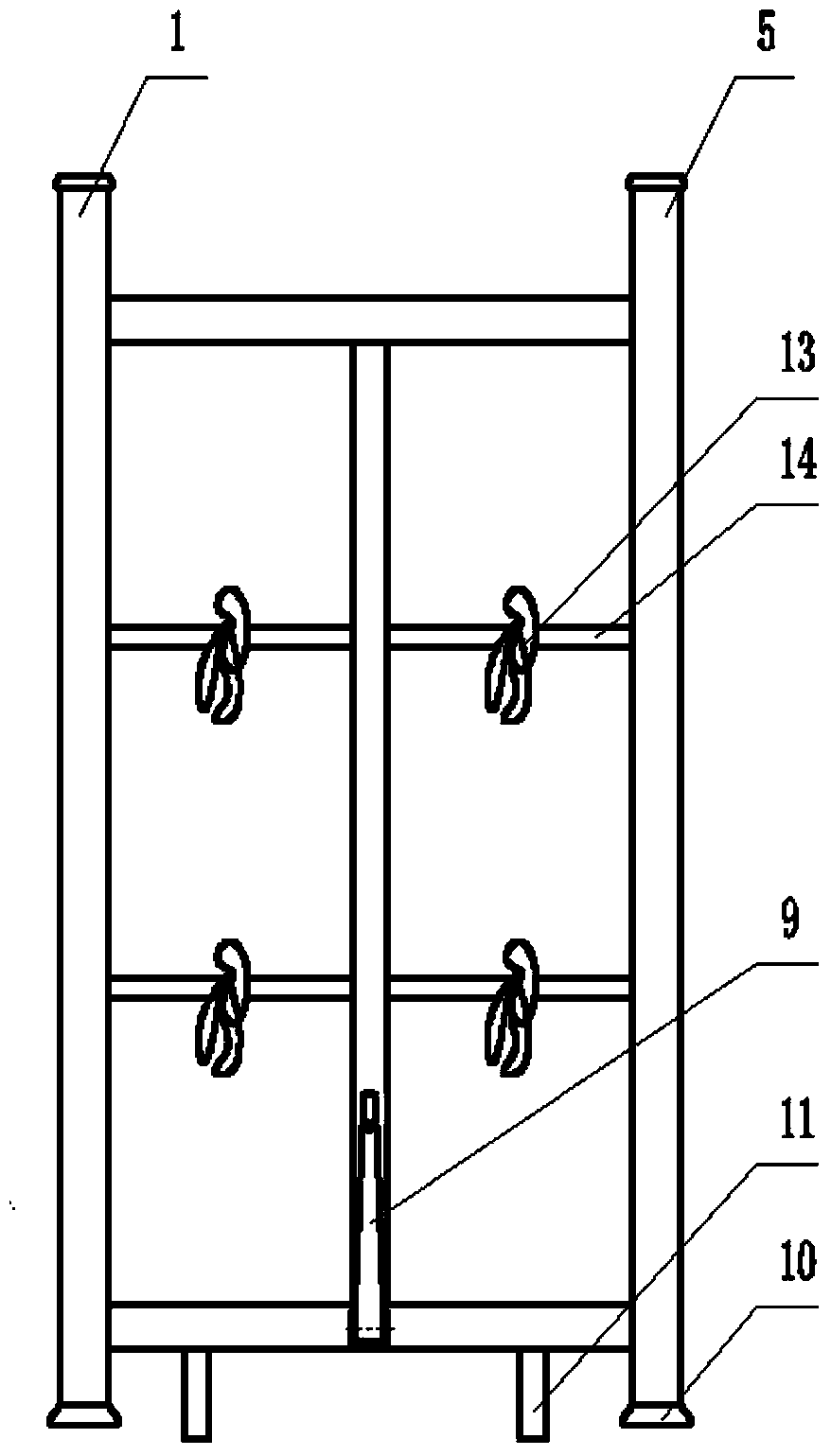

[0023] A kind of automobile hood turnover car, such as figure 1 , figure 2 Shown, comprise the frame body 4 of rectangular structure, cloth curtain 1, liner and wheel 11, two beams 7 are formed at intervals on the front and rear surfaces of the frame body, and two side beams 14 are formed at intervals on the left and right surfaces. The corresponding inner lining is installed in the frame, and the inner lining is made of non-woven fabric material, and the inner lining is divided into three-layer structure through the transverse partition section 8, and each layer is divided into multiple parts that can accommodate the engine hood through the longitudinal partition 3. In a small space, both sides of the lining are connected to the side beams by connecting ropes 13. In order to prevent dust, a cloth curtain is installed in fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com