Dual-motor automatic variable-speed drive system of electric vehicle

An automatic transmission and drive system technology, applied in electric braking systems, electric vehicles, electric power devices, etc., can solve the problems of only a single slow gear, energy waste, increase battery costs, etc., and achieve smooth and stable engagement between gears. , reduce the cost of use and improve the effect of driving mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

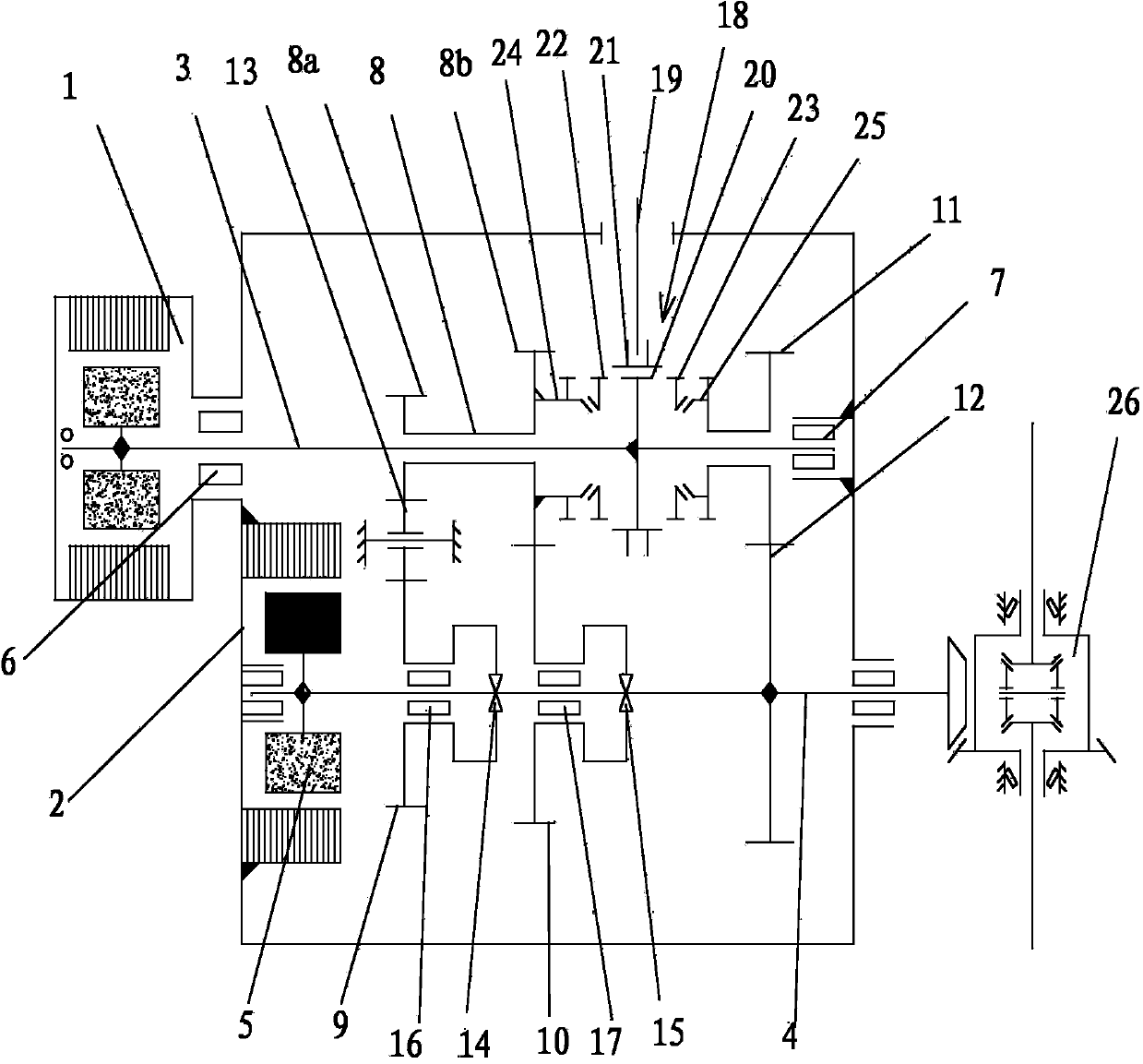

[0019] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure: the dual-motor automatic variable speed drive system of the electric vehicle in this embodiment includes a main motor 1 and a transmission and transmission assembly, and the transmission and transmission assembly includes a box body 2 and a body that can be wound around itself The power input shaft 3 and the power output shaft 4 of the box are arranged in the way of axis rotation, and the main motor 1 can input the power to the power input shaft 3 in the way of forward and reverse switching to realize gear shifting; The dual-motor automatic variable speed driving system of the electric vehicle also includes an auxiliary motor 5 for providing auxiliary output power for the power output shaft 4 when the main motor 1 switches the rotation direction; The purpose of the power input power input shaft, as shown in the figure, the power input shaft, the power output shaft and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com