Pesticide residue degradation system

A control system and equipment technology, applied in the field of pesticide residue degradation system, can solve the problems of long processing time, human and animal poisoning, human health damage, etc., and achieve the effects of short degradation time, no secondary pollution, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

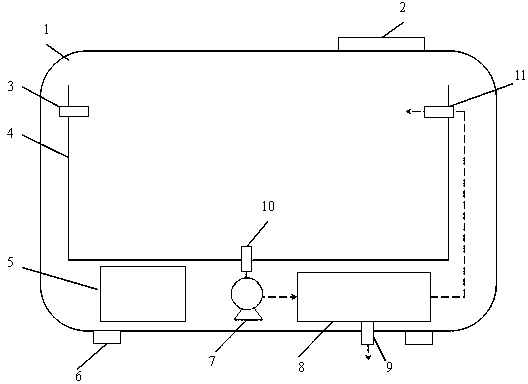

[0032] see figure 1 , the pesticide residue degradation system of the present invention includes an equipment housing 1, a PLC control system, a high-energy particle direct oxidation system and an internal water circulation system, the bottom of the equipment housing 1 is provided with a support foot 6, and the advanced oxidation system and the internal water circulation system The systems are located in the equipment housing 1, and the PLC control system is located on the top of the equipment housing 1;

[0033] The high-energy particle direct oxidation system includes a DC stable power supply 5 and a high-energy particle direct oxidation device 8;

[0034] The internal water circulation system includes an internal water circulation inlet 10, an internal water circulation outlet 11 and a circulation pump 7;

[0035] Described PLC control system comprises PLC control panel 2;

[0036] The equipment casing 1 is provided with a cleaning tank 4, the cleaning tank 4 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com