Refrigeration pretreatment production line for shrimps

A pretreatment and assembly line technology, which is applied in the field of shrimp refrigeration pretreatment equipment, can solve the problems of undiscovered shrimp refrigeration pretreatment equipment, etc., and achieve the effects of avoiding refrigeration consumption and customer purchase costs, shortening thawing time, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

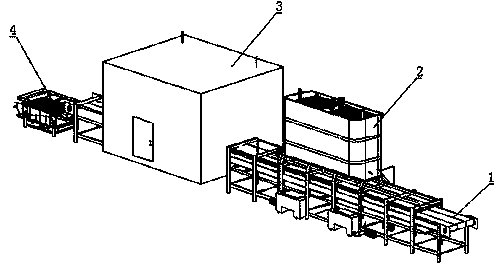

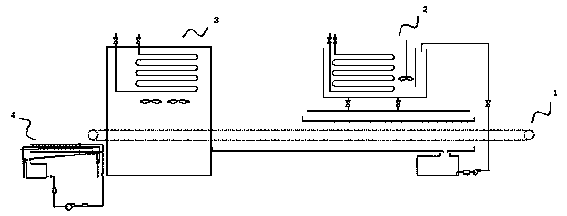

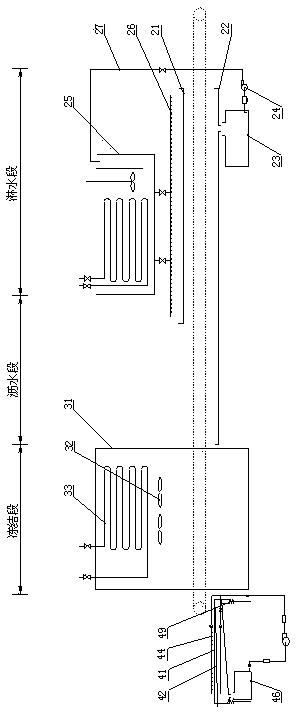

[0026] Such as figure 1 , 2 As shown, it mainly includes conveying mesh belt 1, salt water spray cooling and draining device 2, quick freezing device 3, and vibrating ice-packing device 4. The conveying mesh belt 1 is divided into water-drenching section conveying mesh belts from front to back according to the process requirements , Conveyor mesh belt in the draining section, conveyor mesh belt in the freezing section, install salt water spray cooling and draining device 2 on the conveyor mesh belt in the water spraying section, and set up a quick freezing device 3 on the conveyor mesh belt in the freezing section. The discharge end of the conveying mesh belt is provided with a vibrating ice-packing device 4 .

[0027] The technological functions of the above-mentioned sections are:

[0028] The salt water spray cooling and draining device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com