Grain drying technology

A grain drying and grain technology, applied in drying, drying machines, food processing, etc., can solve the problems of fuel air pollution, high cost of use, and increased burden on farmers, and achieve good social benefits, cost savings, and Outstanding effect of energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

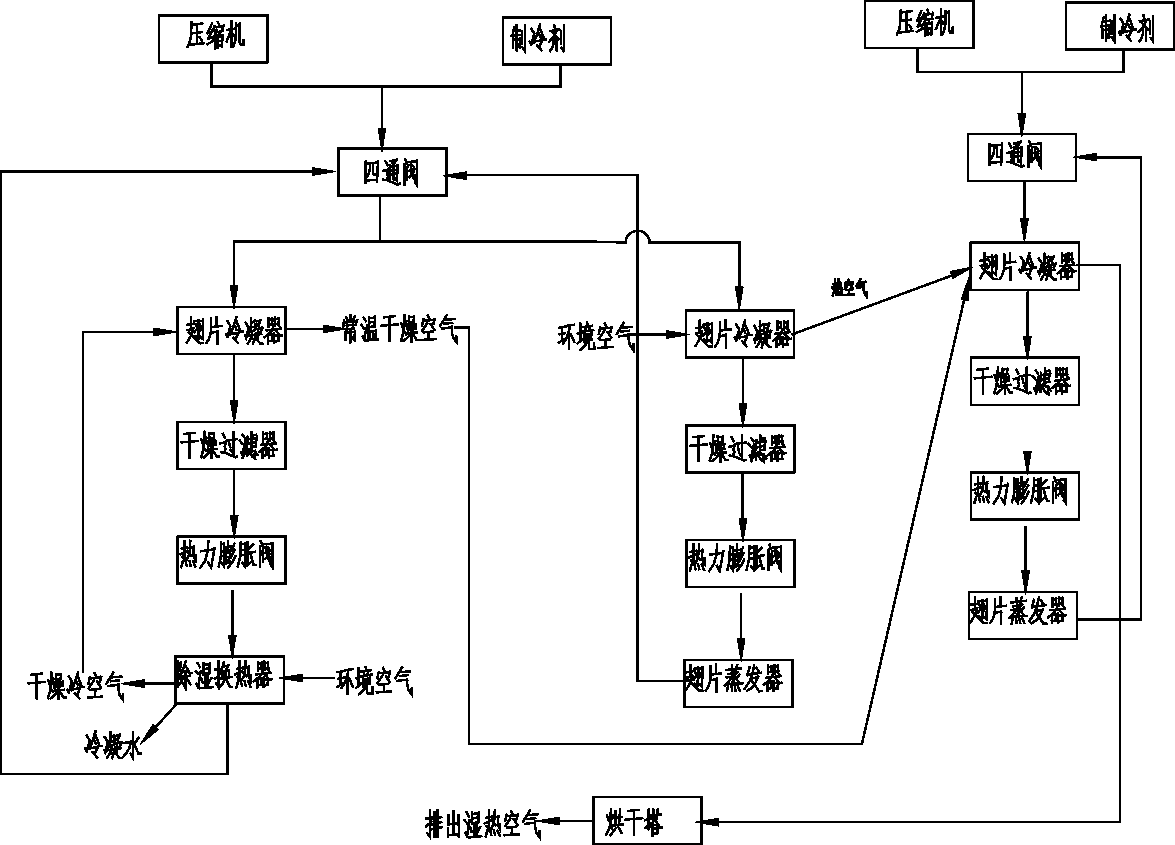

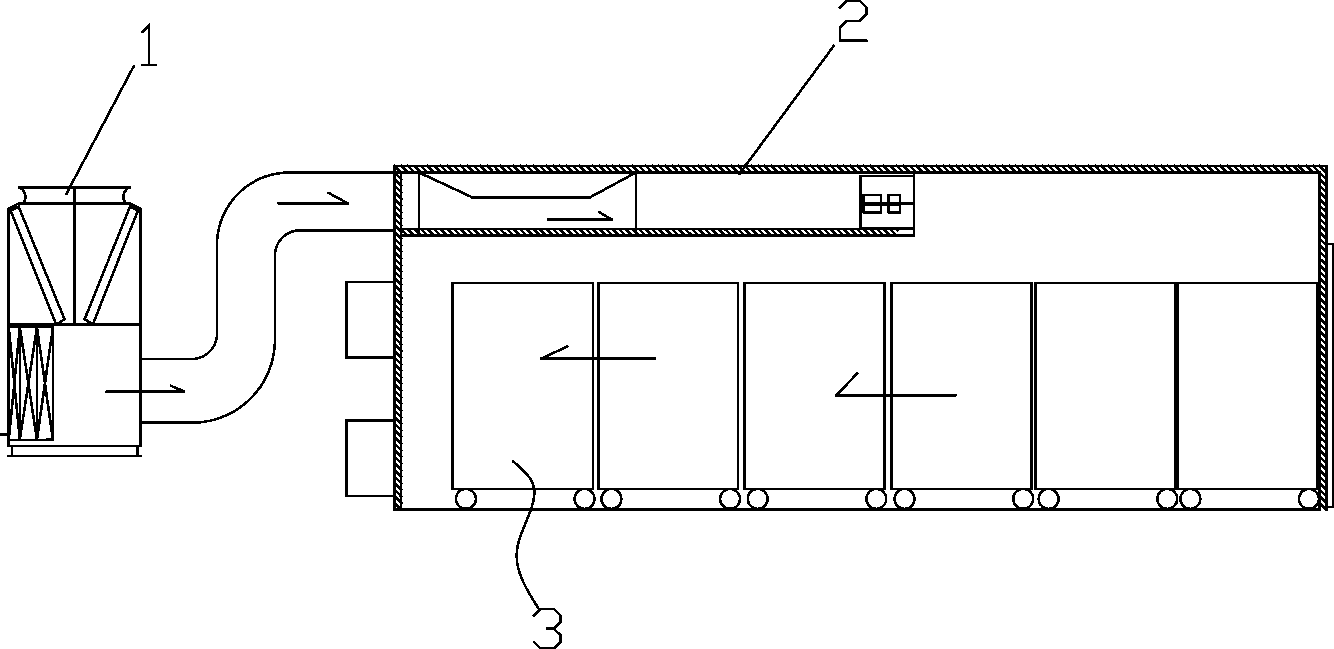

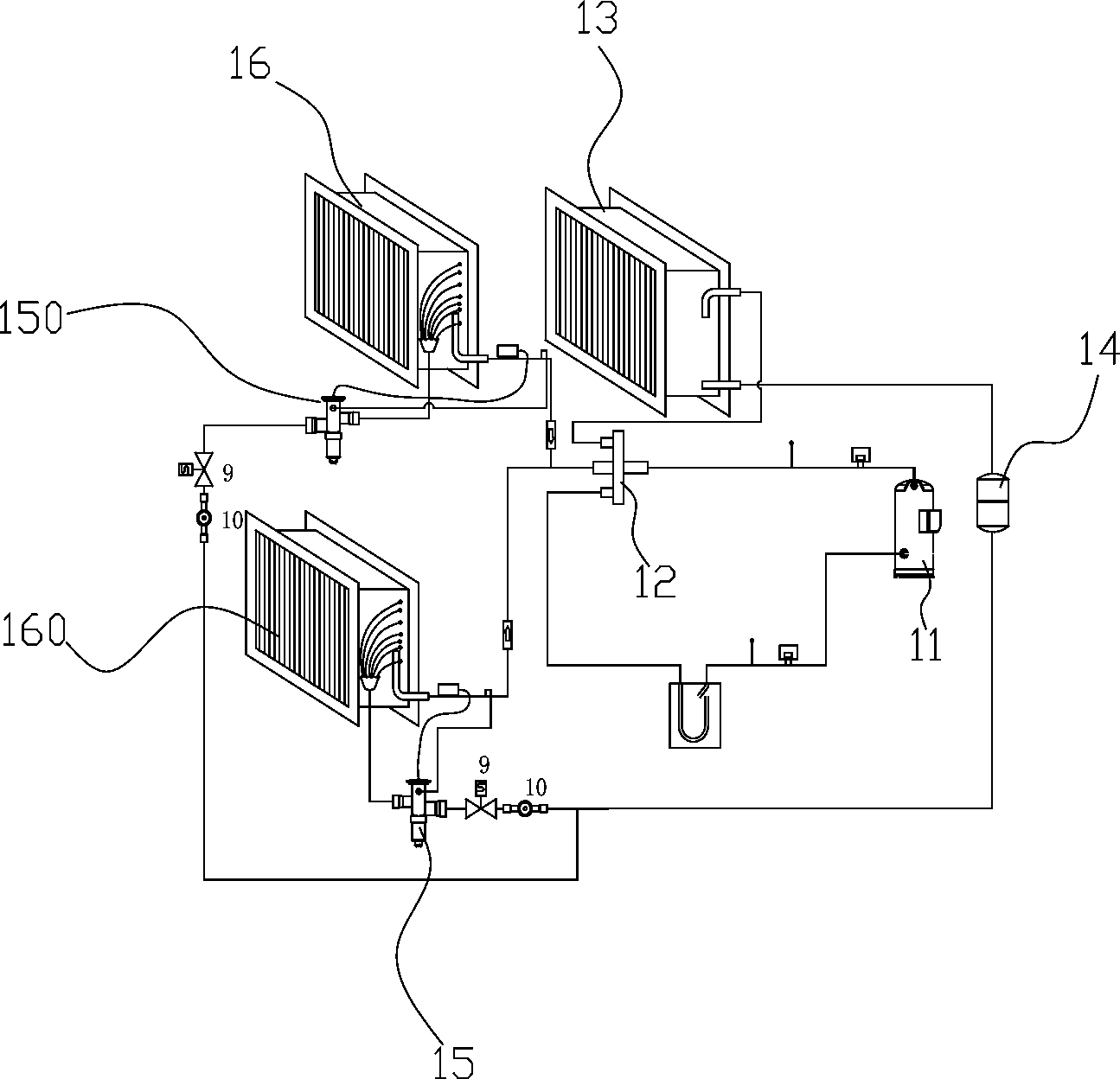

[0017] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 , a grain drying process, characterized in that it includes the following steps: 1) loading the grain into a cart and sending it into a drying tower; 2) starting a heat pump drying unit connected to the drying tower, and the heat pump drying The compressor of the unit enters the high-temperature and high-pressure refrigerant gas into the condenser, and then throttles through the thermal expansion valve. The refrigerant becomes a low-temperature and low-pressure liquid and enters the dehumidification heat exchanger. Compressor, the ambient air is introduced into the air circulation pipeline by the fan, and first passes through the dehumidification heat exchanger to extract the moisture content in the air, and the dry cold air is heated to normal temperature air by the finned condenser to reduce the relative humidity of the air Pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com