A new type of silicon nanomaterial solar cell and its preparation method

A technology of solar cells and new structure, applied in the field of solar cells, can solve the problems of complex preparation process of solar cells, photoelectric conversion efficiency to be improved, difficulty in production and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

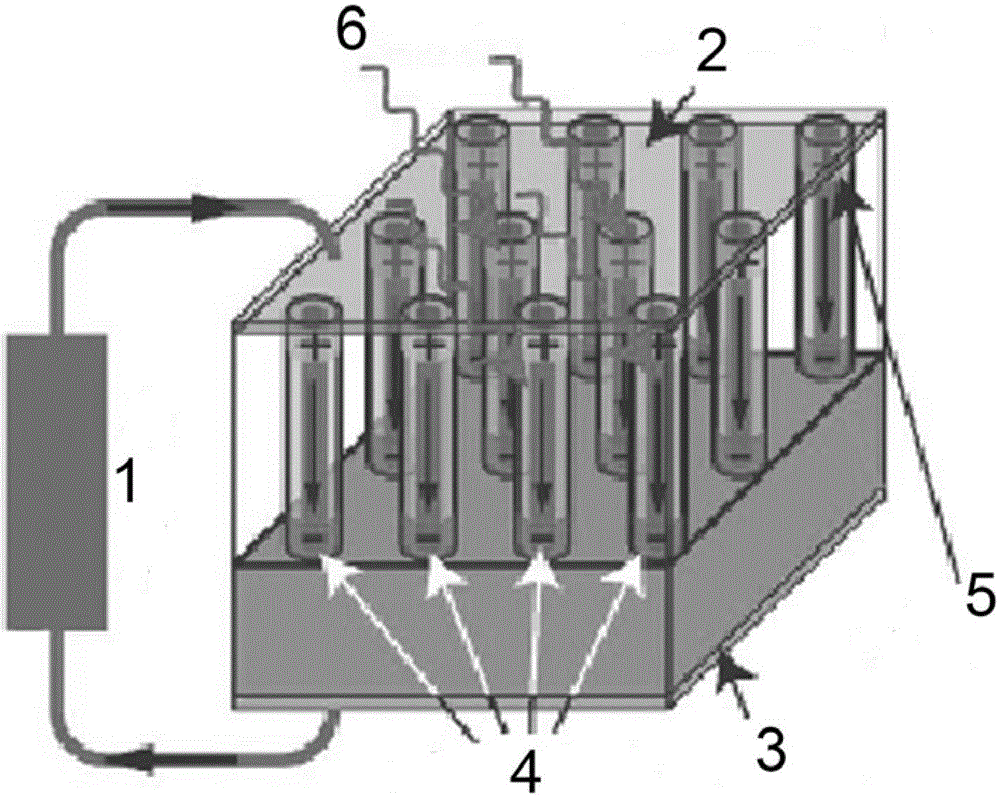

Image

Examples

Embodiment 1

[0030] Put a 5 mm × 5 mm heavily doped silicon wafer in a plastic cup, add 10 ml of ethanol hydrofluoric acid solution with a mass fraction of 5%, and then add silver nitrate solid to obtain a silver nitrate solution with a concentration of 0.1 mol / L. React at 50°C for 2 hours to obtain silicon nanowires, heat the obtained silicon wafer with silicon nanowires in a muffle furnace at 900°C for 5 minutes, use oxygen in the air to partially oxidize the silicon nanowires, and generate a built-in electric field , take out the silicon wafer from the muffle furnace, set the bottom electrode on the bottom of the silicon wafer, the bottom electrode is in ohmic contact with the surface of the silicon wafer, spin coat a layer of conductive glue on the upper part of the silicon wafer (the side with silicon nanowires), and then steam Transparent electrodes, solar cells can be prepared after packaging, and the efficiency can reach 10%.

Embodiment 2

[0032] 20 mg of silicon nanoparticles (purchased from Aldrich, particle size less than 100 nm, CAS No.: 7440-21-3) were irradiated under synchrotron radiation for 1 hour to generate a built-in electric field, and then dispersed in 50 ml of water, Assemble under the action of an electric field or a magnetic field, then spin-coat the suspension on ITO glass, spin-coat the conductive glue after drying, steam the metal electrodes, and package it to make a solar cell with an efficiency of up to 10%.

Embodiment 3

[0034] 20 mg of silicon nanoparticles (purchased from Aldrich with a particle size of less than 100 nm, CAS No.: 7440-21-3) were irradiated with alpha rays for 2 hours to generate a built-in electric field, and then dispersed in 50 ml of dodecyl In the aqueous solution of sodium benzenesulfonate, after being assembled into a film, move it to ITO glass, spin-coat the conductive glue after drying, steam the metal electrode, and package it to make a solar cell with an efficiency of up to 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com