A kind of preparation method of polycrystalline silicon surface micro-nano composite structure

A micro-nano composite structure, polysilicon technology, applied in the application field, can solve the problems of poor repeatability, serious surface compounding, and high consumption of precious metals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

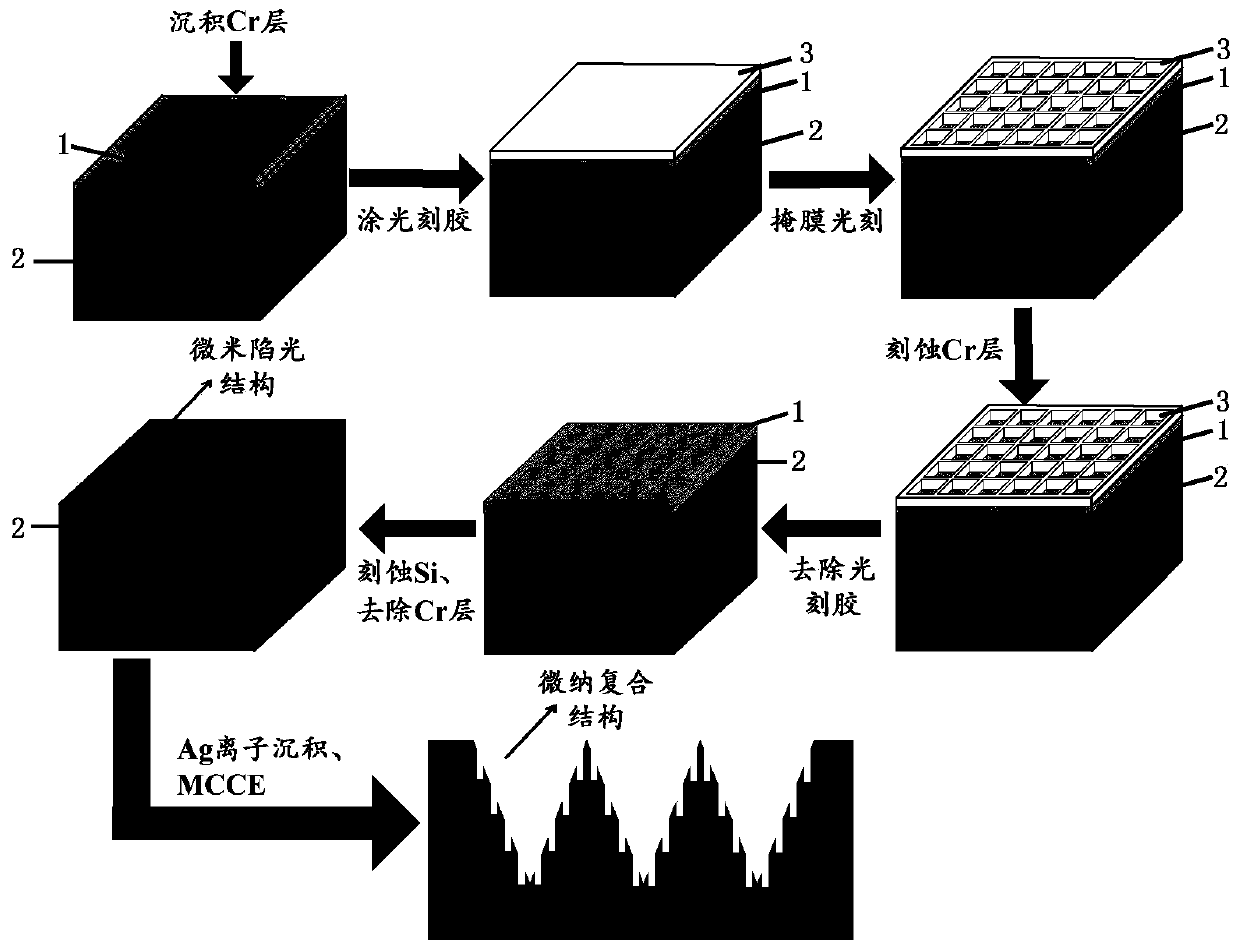

[0014] Specific embodiments: a method for preparing a micro-nano composite structure on the surface of polysilicon, which is completed by the following steps:

[0015] Step 1: the deposition of Cr metal film on the surface of polycrystalline silicon wafer, the steps are as follows: take a polycrystalline silicon wafer sliced by a diamond wire, clean it with absolute ethanol and deionized water, utilize the magnetron sputtering method to coat metal Cr film on polycrystalline silicon wafer, select The high-purity Cr target is used as the sputtering target, and the polysilicon wafer is placed in the vacuum chamber, and the vacuum is first drawn. When the vacuum degree of the equipment is 3.0×10 -5 At Torr, start the Cr target, and then pass in argon gas for 30min ion cleaning; after the ion cleaning process, control the target current to 1A, the substrate bias voltage to 75V, and the gas flow rate to 20sccm for Cr film deposition. By adjusting the deposition time, the polysilico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com