Method for recycling nickel-plated sintered NdFeB waste

A technology of neodymium iron boron and nickel plating, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of power consumption, unqualified coating, time-consuming, etc., save energy consumption and working hours, and facilitate production arrangements , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

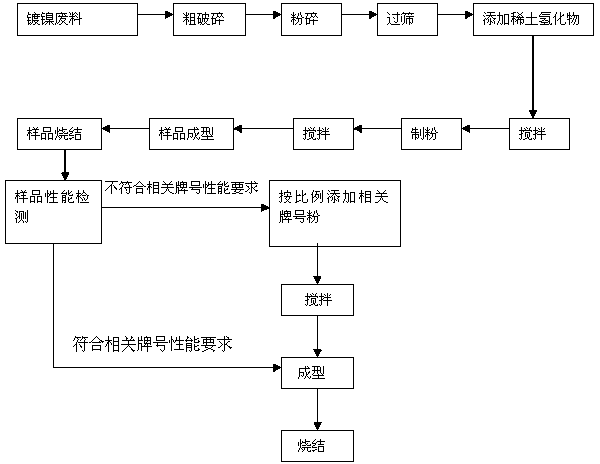

Image

Examples

Embodiment 1

[0016] Use a jaw crusher to roughly crush the collected nickel-plated sintered NdFeB waste into particles below 25mm, and then use a secondary crusher to crush the material into powder with a particle size below 3mm. peeling off;

[0017] The powder is then sieved through a 30-60 mesh sieve in a sealed nitrogen glove box to remove most of the nickel plating flakes;

[0018] Add 2wt% praseodymium neodymium hydride to the sieved powder, stir for 1-3 hours to make the ingredients uniform, then use a jet mill to prepare the powder into a fine powder of 3-5 μm, and stir again for 1-3 hours, every Add 1wt‰—5wt‰ milling additive before the first stirring;

[0019] After the powder is fully stirred and mixed, take an appropriate amount of powder for compression molding and sintering to make 5-20 NdFeB magnet samples for performance testing. The test data is: Br: 12.8—13.2KGS, Hcb: 11.8-12.5 KOe, Hcj: 14.2-15.3KOe, (BH) max: 40.5-43.0MGOe, according to GB / T 13560-2000, its performanc...

Embodiment 2

[0021] Use a jaw crusher to roughly crush the collected nickel-plated sintered NdFeB waste into particles below 25mm, and then use a secondary crusher to crush the material into powder with a particle size below 3mm. peeling off;

[0022] The powder is then sieved through a 30-60 mesh sieve in a sealed nitrogen glove box to remove most of the nickel plating flakes;

[0023] Add 2wt% iron gadolinium hydride to the sieved powder, stir for 1-3 hours to make the ingredients uniform, then use a jet mill to prepare the powder into a fine powder of 3-5 μm, and stir again for 1-3 hours, every Add 1wt‰—5wt‰ milling additive before the first stirring;

[0024] After the powder is fully stirred and mixed, take an appropriate amount of powder for compression molding and sintering to make 5-20 pieces of 52×52×27 NdFeB magnet samples for performance testing. The test data is: Br: 12.2—12.6KGS , Hcb: 11.5-12.2KOe, Hcj: 13.4-14.7KOe, (BH) max: 36.7—38.4MGOe, according to GB / T 13560-2000, it...

Embodiment 3

[0026] Use a jaw crusher to roughly crush the collected nickel-plated sintered NdFeB waste into particles below 25mm, and then use a secondary crusher to crush the material into powder with a particle size below 3mm. peeling off;

[0027] The powder is then sieved through a 30-60 mesh sieve in a sealed nitrogen glove box to remove most of the nickel plating flakes;

[0028] Add 3wt% praseodymium neodymium hydride to the sieved powder, stir for 1-3 hours to make the ingredients uniform, then use the jet mill to prepare the powder into a fine powder of 3-5 μm, and stir again for 1-3 hours, every Add 1wt‰—5wt‰ milling additive before the first stirring;

[0029] After the powder is fully stirred and mixed, take an appropriate amount of powder for compression molding and sintering to make 5-20 pieces of 52×52×27 NdFeB magnet samples for performance testing. The test data is: Br: 12.6—12.9KGS , Hcb: 11.5-12.2KOe, Hcj: 14.8-16.1KOe, (BH) max: 38.8—41.3MGOe, according to GB / T 13560...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com