On-line calibration method of electronic watt-hour meter

A calibration method and technology of electric energy meters, which are applied in the direction of measuring electrical variables, measuring devices, instruments, etc., can solve problems affecting production and production measurement, safety accidents, and the accuracy of measurement data of oil well electrical parameters cannot be grasped, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

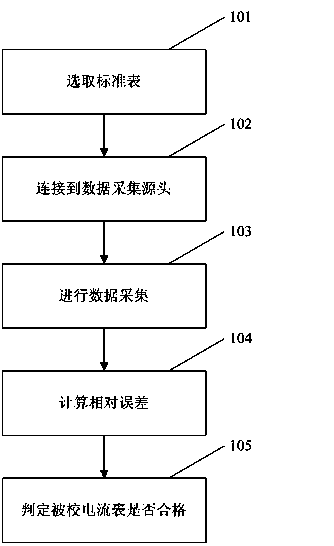

[0022] Such as figure 1 as shown, figure 1 It is a flow chart of a specific embodiment of the online calibration method of the electronic energy meter of the present invention.

[0023] In step 101, a standard table required for online calibration is selected. The standard meter can measure real-time data such as three-phase voltage, three-phase current, active power, reactive power, power factor, etc., and measure forward and reverse active energy and forward and reverse reactive energy. The accuracy level of the standard meter is at least one level higher than that of the meter being calibrated on site, and its pulse constant is correspondingly at least twice as large. In a specific embodiment, the accuracy of the electronic watt-hour meter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com