Pipeline steering mechanism of crane type marine cryogenic fluid filling device

A technology for cryogenic fluids and filling equipment, which is applied in mechanical equipment, equipment loaded into pressure vessels, pipes/pipe joints/pipe fittings, etc., and can solve problems such as difficulty in meeting user requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

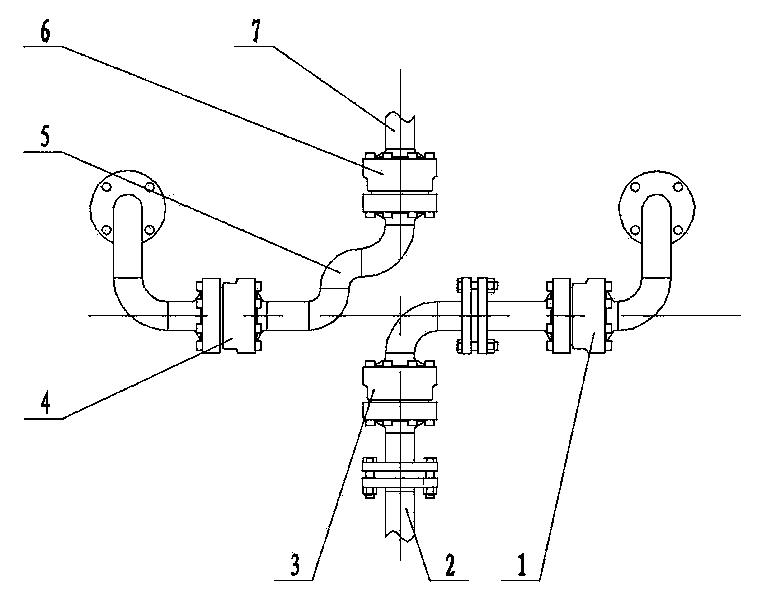

[0007] A pipeline steering mechanism for crane-type marine low-temperature fluid filling equipment, including horizontal rotary joints I6 and horizontal rotary joints II3 facing up and down, vertical rotary joints I4 and vertical rotary joints II1 facing left and right , the rotation axes of the horizontal rotary joints I, II6, 3 intersect the rotation axes of the vertical rotary joints I, II4, 1; the horizontal rotary joint I6 and the vertical rotary joint I4 pass through an elbow assembly 5 The upper end of the horizontal rotary joint I6 is connected with a vertical gas phase fixed pipe 7, and the outer end of the vertical rotary joint I4 is connected with a main gas phase tube; the horizontal rotary joint II3 and the vertical rotary joint II1 The lower end of the horizontal rotary joint II3 is connected with the liquid phase fixed tube 2 coaxial with the gas phase fixed tube 7, and the outer end of the vertical rotary joint II1 is connected with the main liquid phase tube pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com