Speed changing device of electric car and gear shifting assembly

A speed change device and component technology, applied in the direction of transmission, gear transmission, transmission control, etc., can solve the problems of reduced service life of the motor, insufficient power, high impact noise, etc., to reduce volume and weight, and facilitate maintenance , the effect of saving internal space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (Example 1, gear shift assembly)

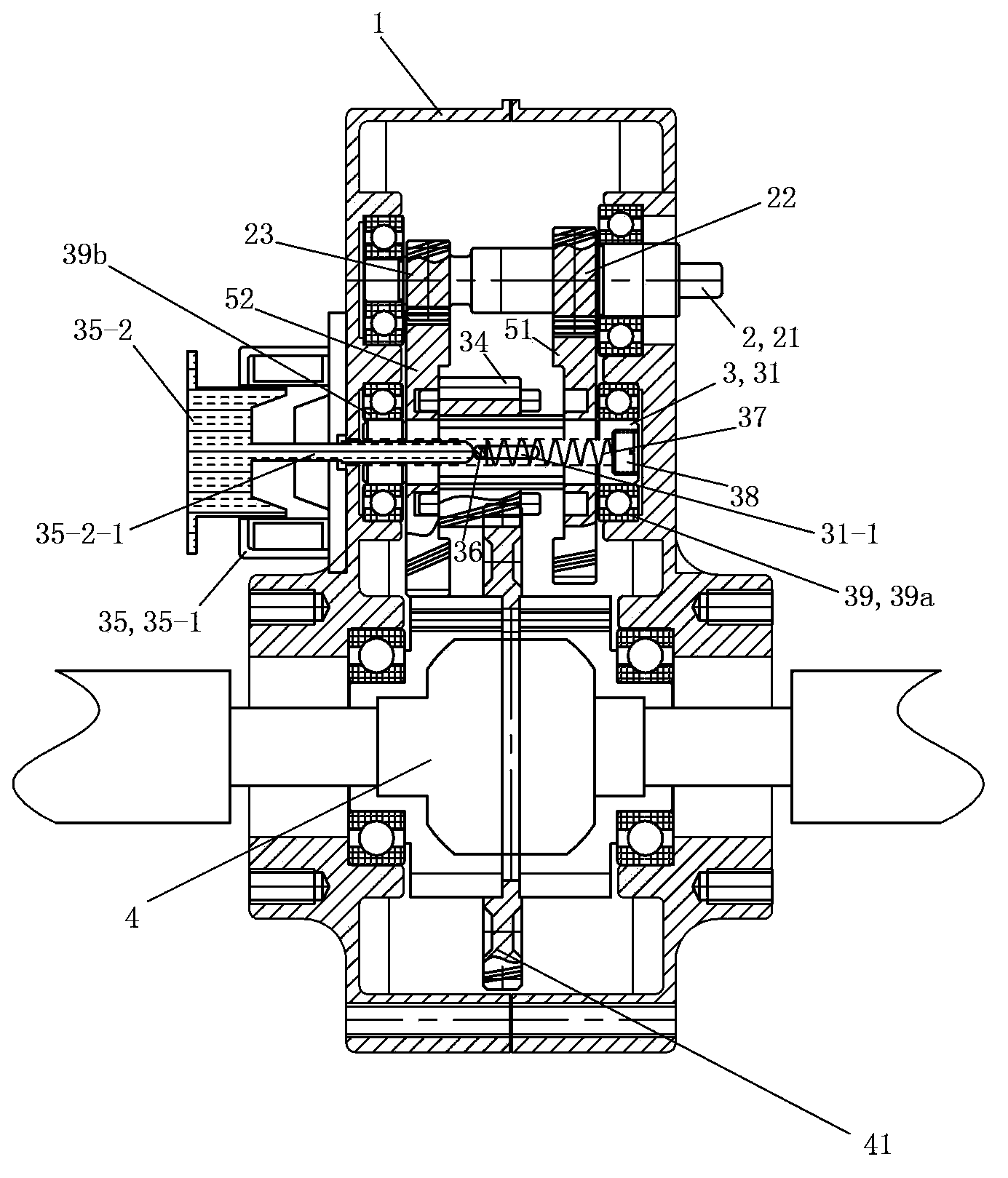

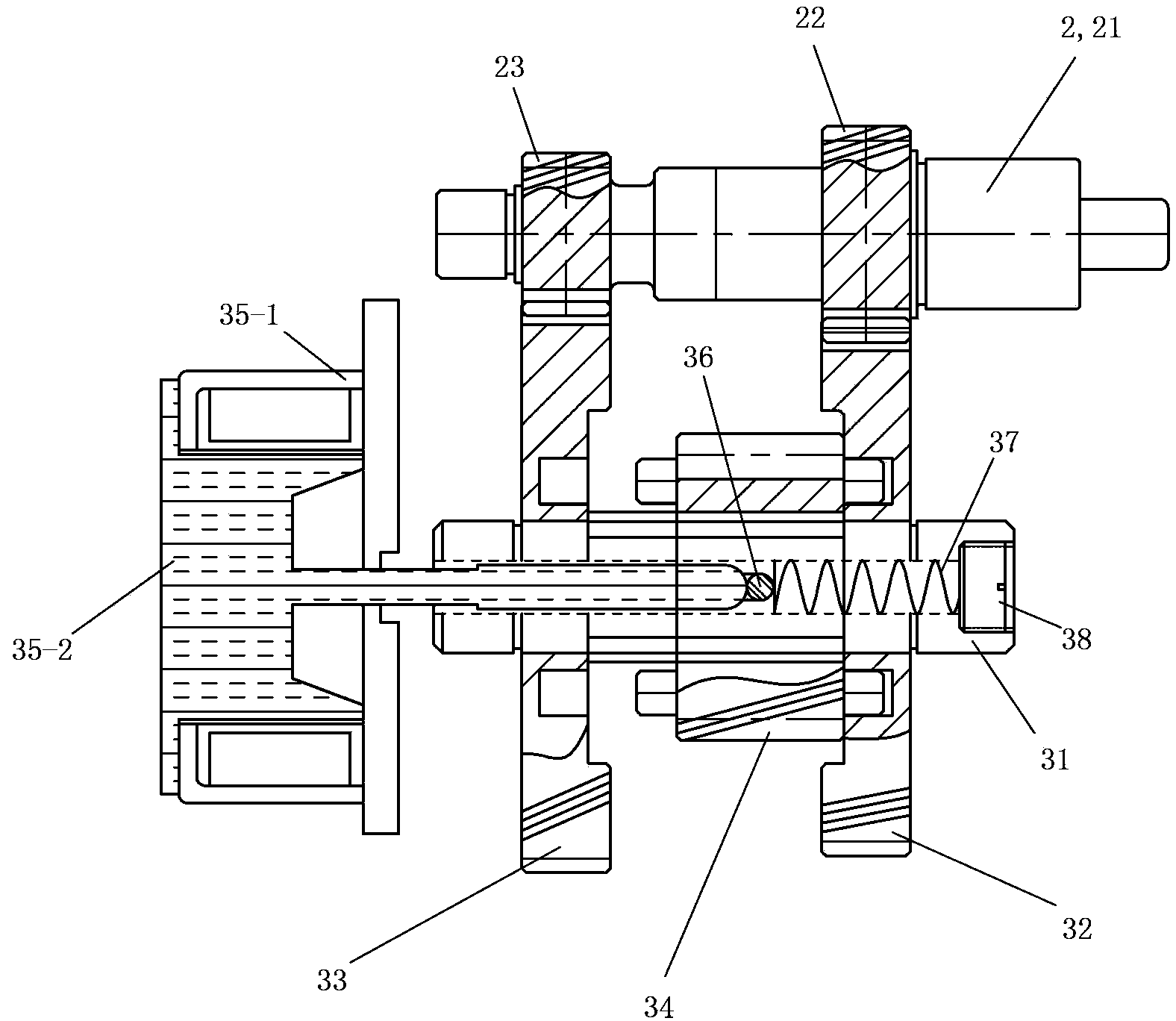

[0050] see figure 2 with image 3 , The shift assembly 3 of the present invention includes a spline shaft 31, a clutch member 34, an electromagnet 35, a circular pin 36, a spring 37 and a top cover 38. The shifting assembly 3 of the present invention can be manually controlled, or it can cooperate with an automatic control system and be controlled by an automatic control system.

[0051] see figure 2 with image 3 , The main axis of the spline shaft 31 is horizontally arranged in the left and right direction, and the spline 31-1 of the spline shaft 31 is arranged in the direction of the main axis, and the spline shaft 31 is also provided with an internal cavity 31-2 along its axis. The internal cavity 31-2 is a through hole penetrating the left and right sides of the spline shaft 31 along the axis of the spline shaft 31. The right port of the through hole of the spline shaft 31 is provided with an internal thread. The spline shaft 31 is...

Embodiment 2

[0052] (Example 2, gear shift assembly)

[0053] The rest of this embodiment is the same as Embodiment 1, and the difference is that: the shift assembly 3 of this embodiment does not include a top cover 38. The internal cavity 31-2 is a blind hole with an opening to the left. The spring 37 is arranged in the blind hole, on the right side of the round pin 36, and is in a compressed state.

Embodiment 3

[0054] (Example 3, shift assembly)

[0055] see Picture 11 The rest of this embodiment is the same as the first embodiment, the difference is: it also includes an output gear 30, the output gear 30 is provided with internal splines, the internal splines of the output gear 30 and the splines 31-1 of the spline shaft 31 Match. The output gear 30 is sleeved on the spline 31-1 of the spline shaft 31 in a transmission matching manner, and the output gear 30 is located on one of the left and right sides of the clutch member 34 (the right side in this embodiment).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com