Cleaning fiber and method for using cleaning fiber for cleaning well

A fibrous, clean technology that can be used in wellbore flushing, earthmoving, wellbore/well components, etc., to solve problems such as labor and time-consuming, downhole collapse, and increased operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

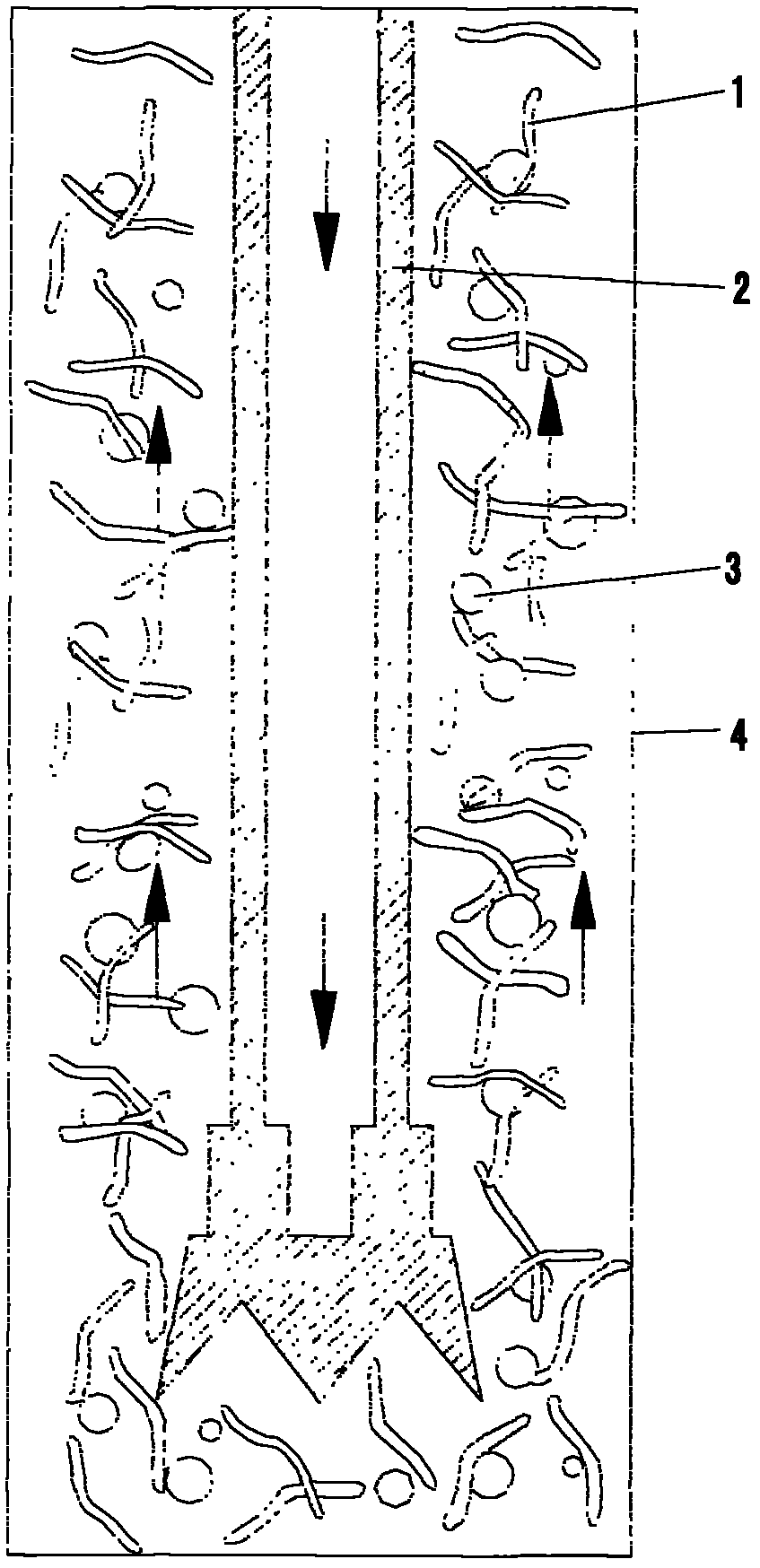

[0018] Such as figure 1 As shown, the cleaning fiber 1 of the present invention is made of virgin monofilament polypropylene material. The cleaning fiber 1 is filamentous, with a length of 12-13 mm and a diameter of 21 microns. The cleaning fiber 1 is compatible with all water-based , oil-based and other drilling fluid systems are compatible.

[0019] Such as figure 2 Shown is the method of using the cleaning fiber to clean the well, which includes the following steps:.

[0020] (1) Put 15-30 cubic meters of drilling fluid in the upper water tank, and add 5-10 cubic meters of drilling fluid if the wellbore condition is complicated;

[0021] (2) Add 1.0-1.2KG of the cleaning fiber 1 per cubic meter of drilling fluid for mixing, and the total adding time is controlled at 30 minutes;

[0022] (3) Stir the mixed drilling fluid and cleaning fiber 1 for about 2 hours, and fully stir the fiber cleaning slurry for use;

[0023] (4) According to the normal displacement, the fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com