The structure and manufacturing method of the double-vacuum layer suction port

A technology of air extraction and double vacuum, which is applied in the direction of manufacturing tools, glass forming, glass reshaping, etc., can solve the problems of weakening the airtightness of solder performance, not necessarily good economic benefits, complex vacuuming process, etc., to achieve extended Long service life, simple structure, and good airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

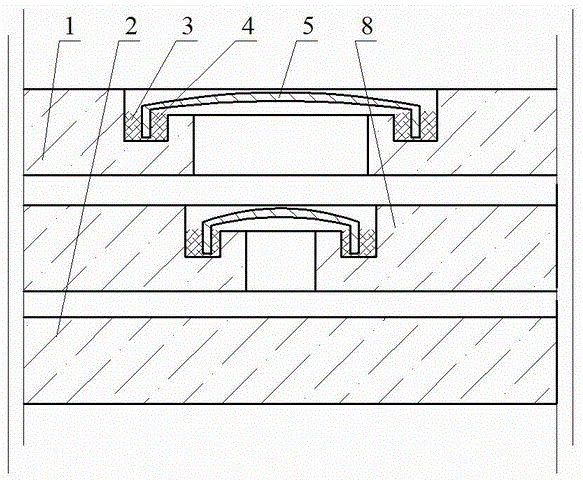

[0055] Embodiment 1: see figure 1 , the vacuum glass is composed of upper glass 1, lower glass 2 and middle glass 8. A through hole is drilled on the upper glass 1 and middle glass 8 respectively to form a suction port, wherein the through hole on the upper glass 1 is larger than the through hole on the middle glass 8 ; On the upper surface of the upper glass 1 and the middle glass 8, use a hollow drill to make a U-shaped sealing groove 4 concentric with the air inlet, and the inner side of the sealing groove 4 is lower than the upper surface of the upper glass 1 and the middle glass 8; Make a seal cover 5 respectively according to the size of seal groove 4, the edge portion of seal cover 5 can insert in the seal groove 4 respectively, the height of seal cover 5 is lower than the upper surface of upper glass 1, between seal cover 5 and seal groove 4 It is an air extraction channel; the inner surface of the sealing groove 4 is coated with metal paste, and then sent into a tempe...

Embodiment 2

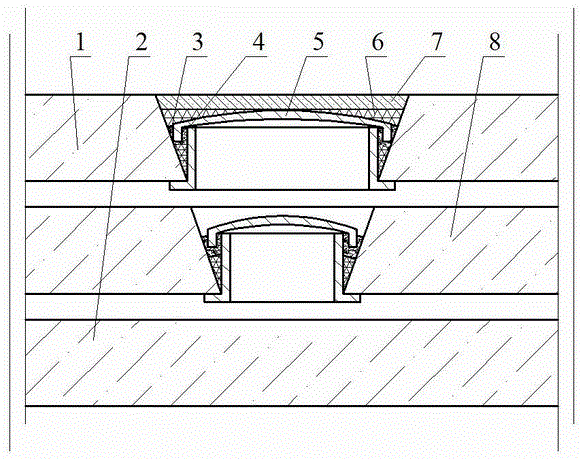

[0056] Example 2: see figure 2 , the vacuum glass is composed of upper glass 1, lower glass 2 and middle glass 8. A V-shaped through hole is drilled on the upper glass 1 and the middle glass 8 respectively to form a suction port, and a circular tube with a lower edge is respectively prepared and inserted into the suction port. In the gas port, the top of the round tube is lower than the upper surface of the upper glass 1 and the middle glass 8, and the round tubes are closely matched with the lower openings of the air inlet respectively, and a sealing groove 4 is formed between the round pipe and the upper part of the air inlet, and the sealing groove Place glass solder at the bottom of 4, and weld the round tube with the upper glass 1 and the middle glass 8 respectively during edge sealing; according to the size of the sealing groove 4, make a sealing cover 5 respectively, and the edge of the sealing cover 5 can be inserted into the sealing In the groove 4, the height of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com