Transferring and placing device for bead cores

A bead core and loading technology, which is applied in the field of bead core transfer and placement devices, can solve the problems of reduced operation efficiency and increased equipment cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

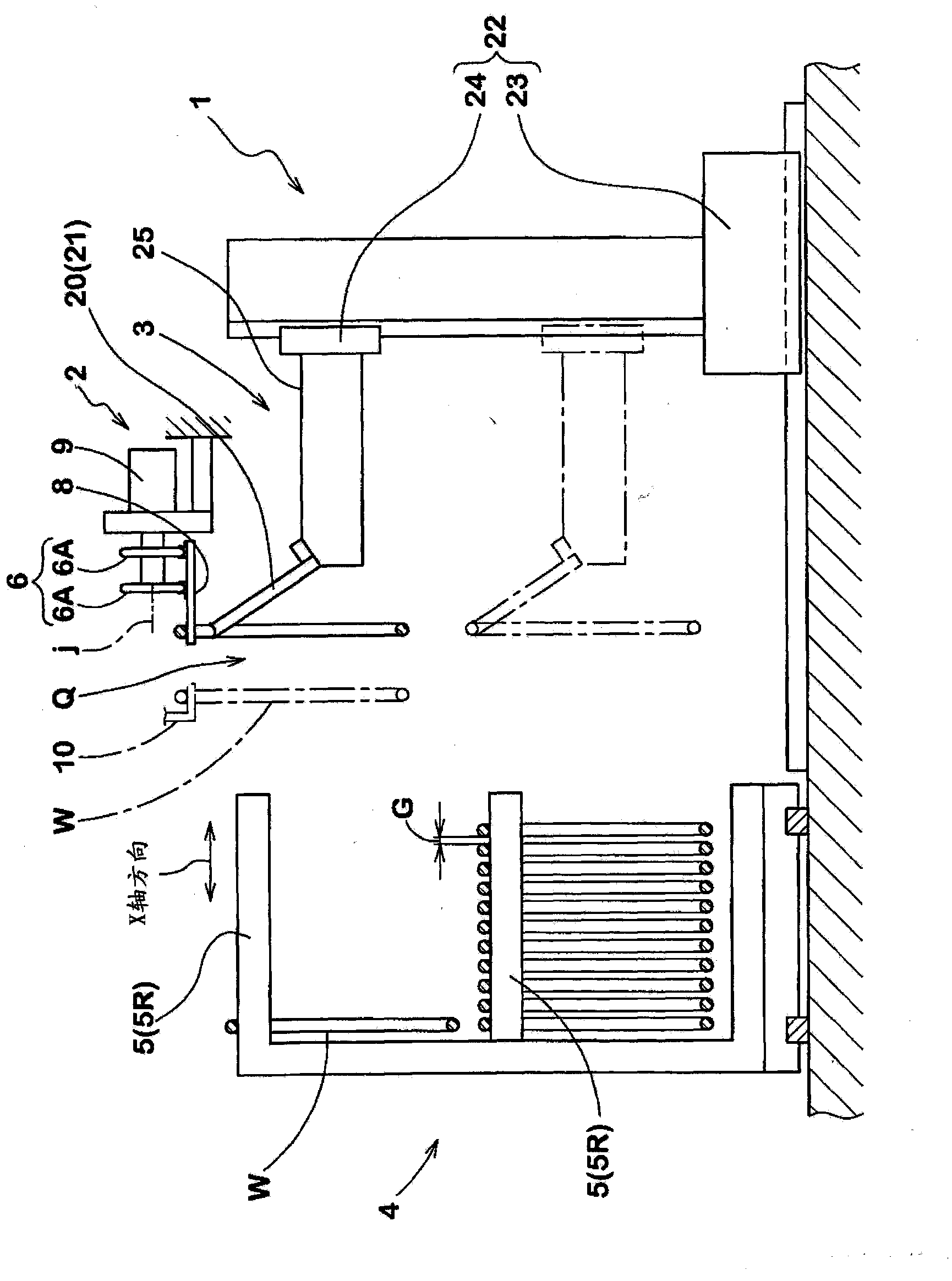

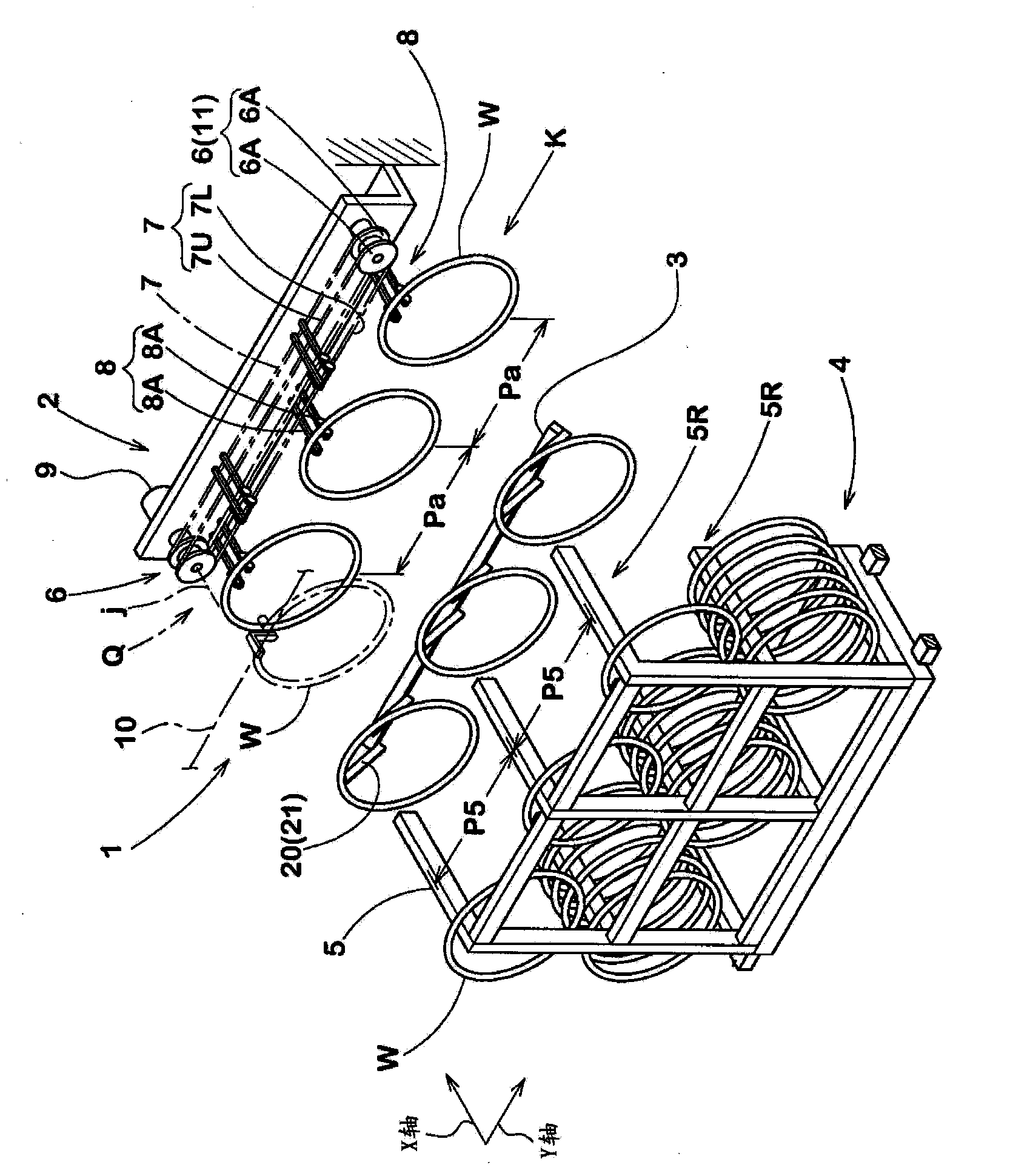

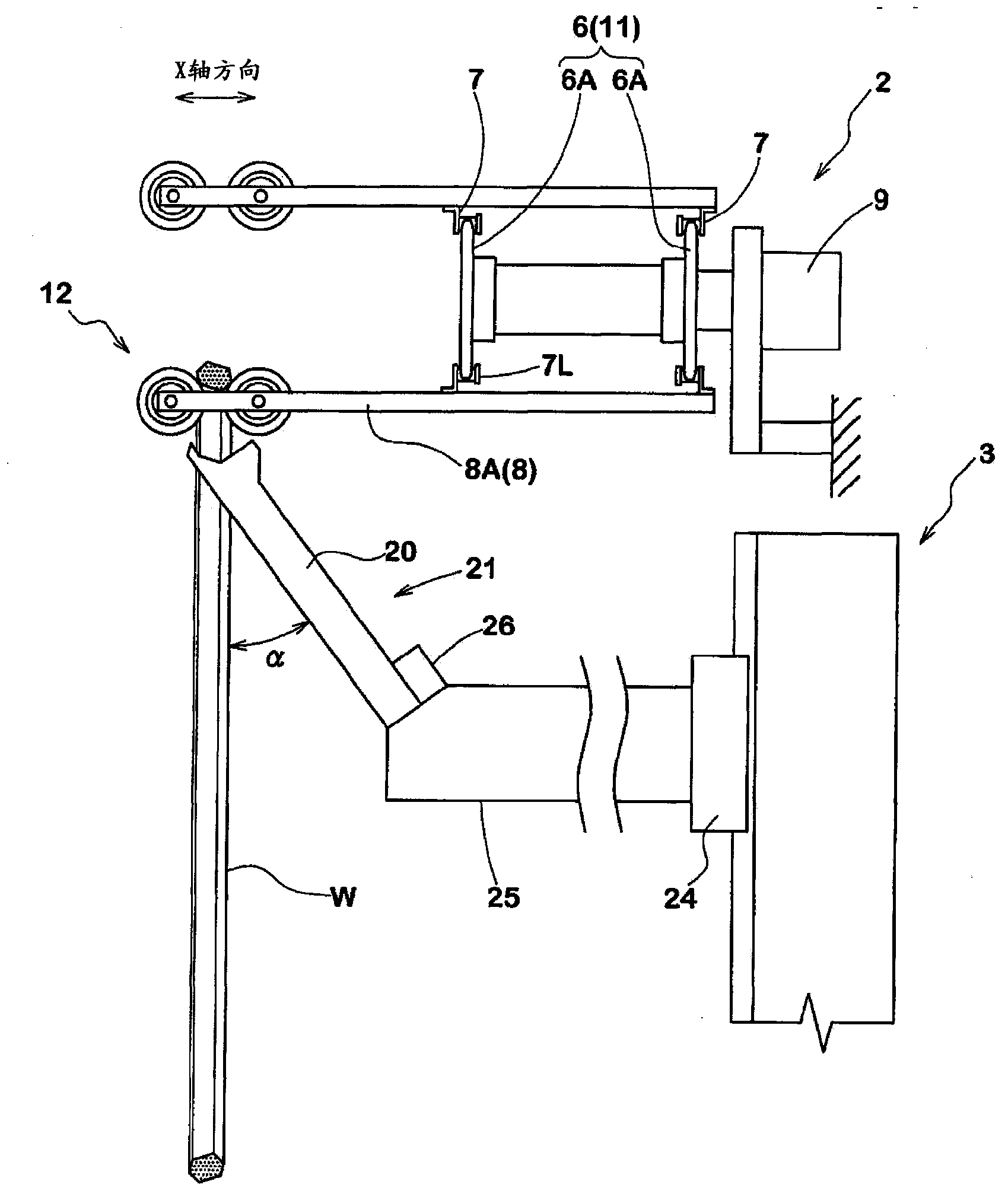

[0032] Hereinafter, embodiments of the present invention will be described in detail. Such as figure 1 , 2 As shown, the bead core transfer and placement device 1 according to this embodiment has an alignment unit 2 and a transfer placement unit 3 , and transfers and places the bead core W supplied from the delivery position Q on the holding arm 5 of the transport cart 4 . .

[0033] The conveyance cart 4 has a well-known structure, and a plurality of holding arms 5 extending horizontally in the X-axis direction includes holding arm rows 5R arranged in the Y-axis direction perpendicular to the X-axis and horizontally. In this example, the conveyance cart 4 has, for example, two upper and lower holding arm rows 5R, 5R, and each holding arm row 5R is formed of three holding arms 5 . Each of the above-mentioned holding arms 5 is supported in a cantilever shape, and the bead core W inserted from the free end side is hooked to the inner peripheral side of the bead core W to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com