A plastic garbage melting treatment box and a method for making plastic bricks

A technology for plastic waste and disposal boxes, applied in the direction of plastic recycling and recycling technology, can solve the problems of lack of preliminary treatment of plastic waste, pollution, etc., and achieve the effect of small footprint, high density and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

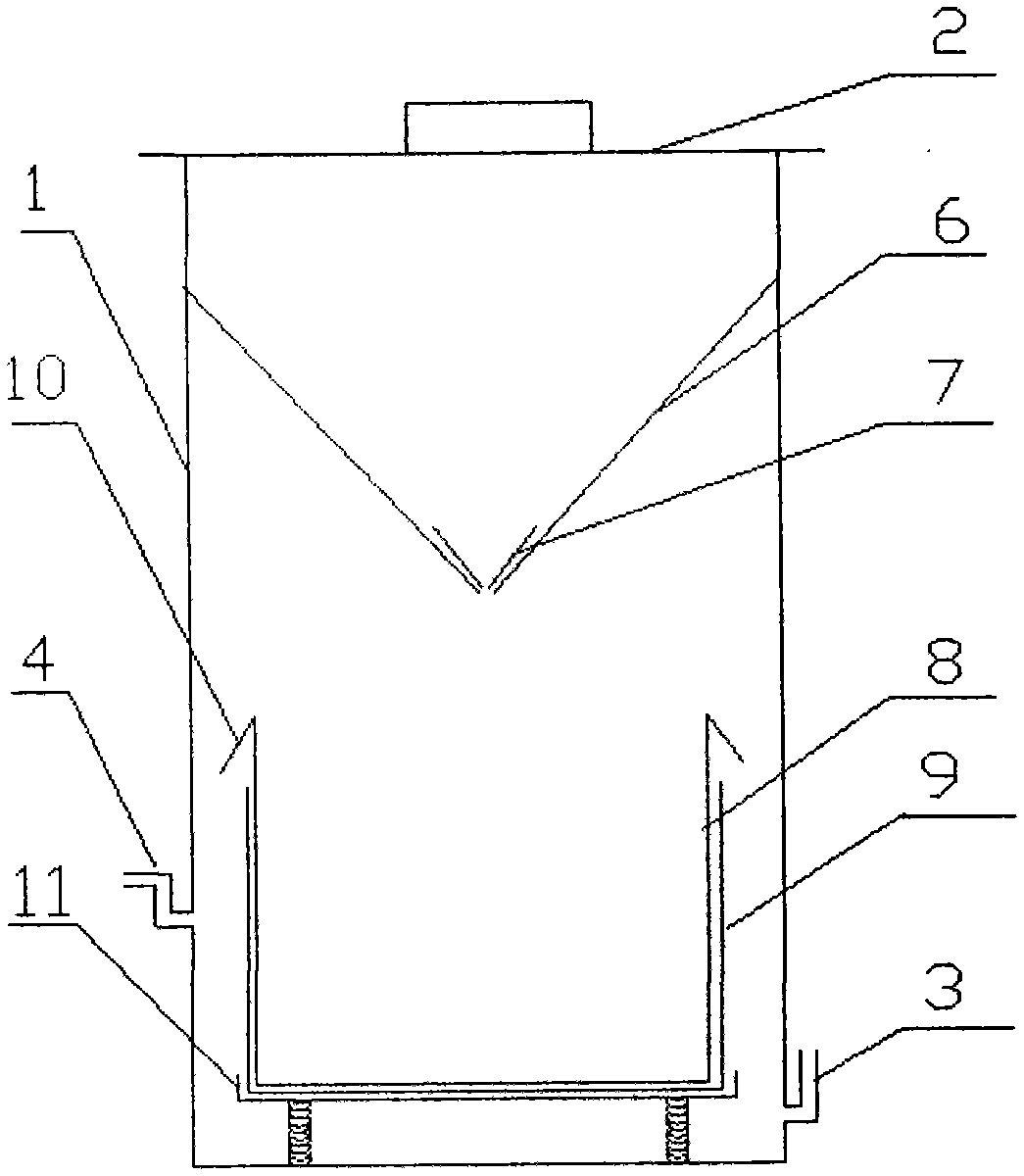

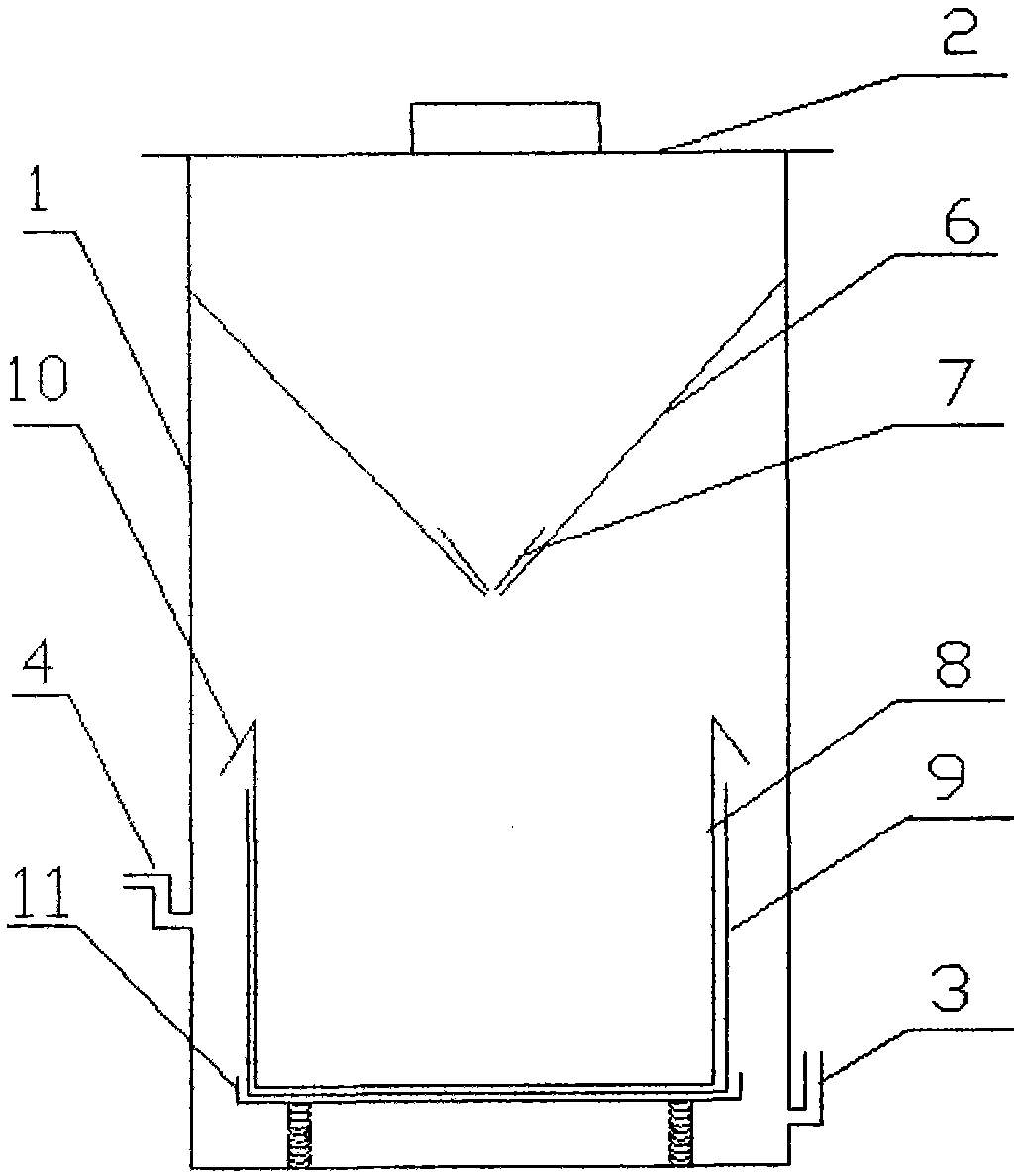

[0027] Such as Figure 1-2 As shown, a plastic garbage melting treatment box described in the embodiment of the present invention includes a box body 1 and a top cover 2 located at the top of the box body 1, and the inside of the box body 1 is provided with a melting bucket 6, a collection box 9, and a support base 11. The melting hopper 6 is connected to the inner upper end of the box body 1, which is close to the top cover. The lower end of the inner melting hopper 6 is provided with a heating plate 7. The support base 11 is fixedly connected to the bottom of the box body 1 by a spring. The collection box 9 Placed on the top surface of the support base 11.

[0028] The preferred cuboid shape of casing 1, the right side of casing 1 is provided with inlet pipe 3, the left side of casing 1 is provided with outlet pipe 4, and the front of casing 1 is provided with a small door 5, facilitates plastic block to take out; Collecting box 9 preferably cuboid Shape, collection box 9 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com