Cutting device

A technology of cutting device and hydraulic device, applied in the direction of driving device, maintenance and safety accessories, manufacturing tools, etc., can solve the problems of high production and manufacturing cost, inconvenient assembly and adjustment, high environmental requirements, etc., to ensure quality and work. efficiency, reducing the effect of uneven deformation fields, reducing size effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0029] This embodiment relates to a kind of micro-cutting technology, which is different from ordinary cutting. During micro-cutting, the cutting depth is usually from micron to nano-level, while the grain size of general materials is several microns. The cutting process is to cut the grains one by one, which will inevitably lead to a sharp increase in the cutting stress per unit area, thereby generating a great deal of heat on the unit area of the cutting edge, causing the temperature at the tip to rise. High, in high temperature, high stress working condition.

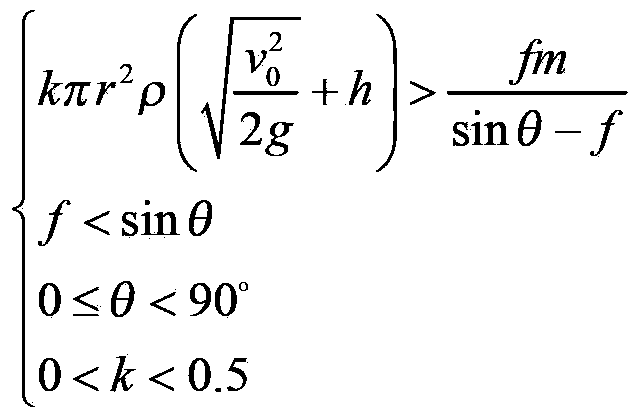

[0030] In order to solve the above problems in the micro-machining process, such as Figure 1 to Figure 8 As shown, the present embodiment proposes a novel cutting device, which includes a particle knife, a cutting workbench 3, a micro-jet nozzle 4 above the workbench 3 and a hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com