Band saw machine capable of adjusting the cutting angle of the band saw

A band saw machine and a technology for adjusting the band, which is applied to metal sawing equipment, sawing machine devices, metal processing equipment, etc., can solve the problems of worn-out band saw service life, acceleration, and insufficient applicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

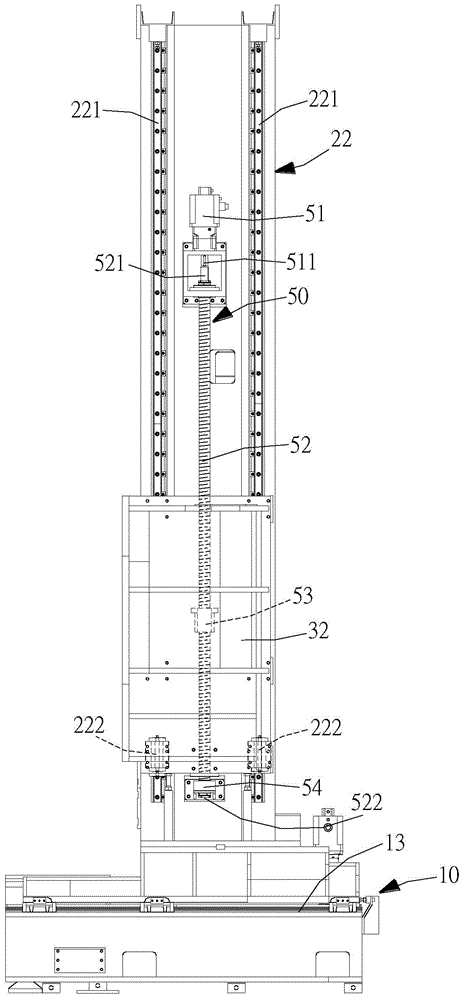

[0057] like Figures 1 to 4 and Figure 7 As shown, a band saw machine capable of adjusting the cutting angle of the band saw provided by the embodiment of the present invention mainly consists of a machine platform 10, a first saw base 21, a second saw base 22, a first saw Table 31, a second saw table 32, a first drive unit 40, a second drive unit 50, a band saw unit 60, and a band saw adjustment unit 70, wherein:

[0058] The machine 10 has a working platform 11 , a first side 12 disposed on one side of the working platform 11 , and a second side 13 disposed on the other side of the working platform 11 .

[0059] like Figure 2 to Figure 6 , the first saw seat 21 can be horizontally moved on the first side portion 12, and has two first slide rails 211 longitudinally arranged on the first saw seat 21, and a plurality of sliding rails 211 arranged on each of the first saw seats. For the first sliders 212 of the slide rails 211 , only one slider is shown on each of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com