Integral press split molding equipment and technology

A separate mold and press technology, applied in the field of molding equipment and technology, can solve the problems of large power consumption of steel plate pressing, high power configuration of the press, and high equipment cost, so as to solve the problems of restraining stretching defects, reducing power configuration, The effect of reducing mold wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

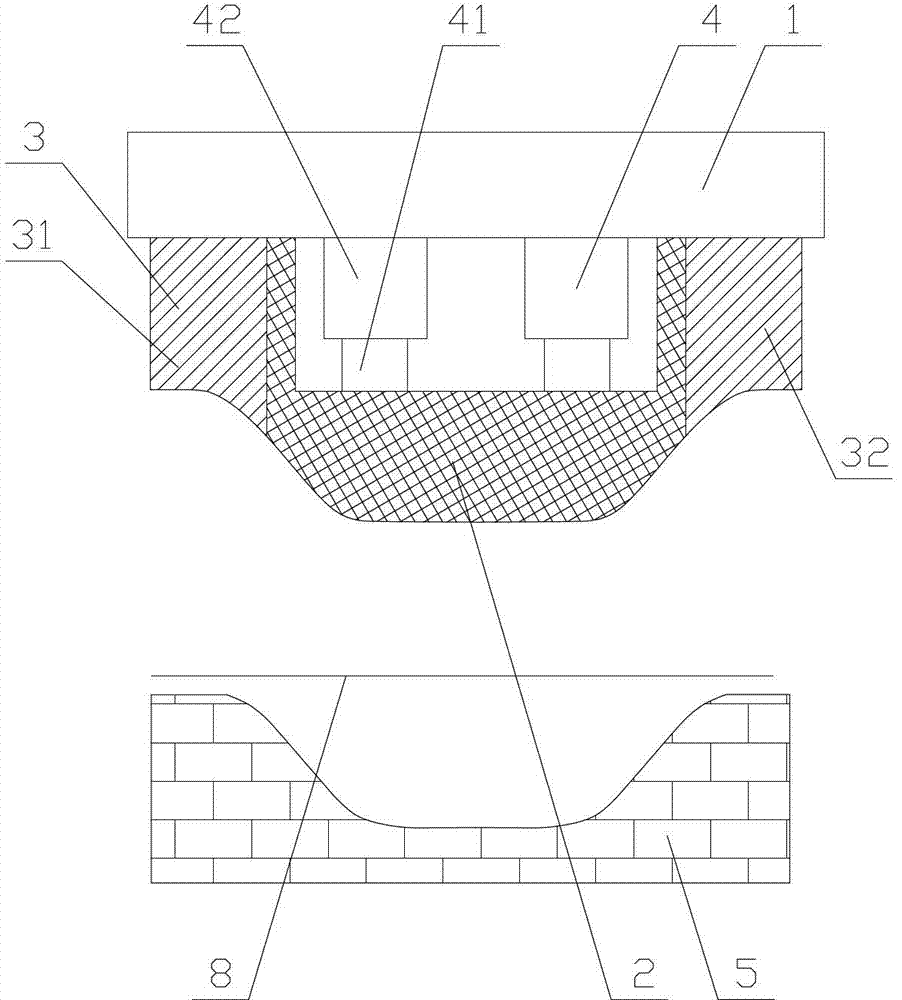

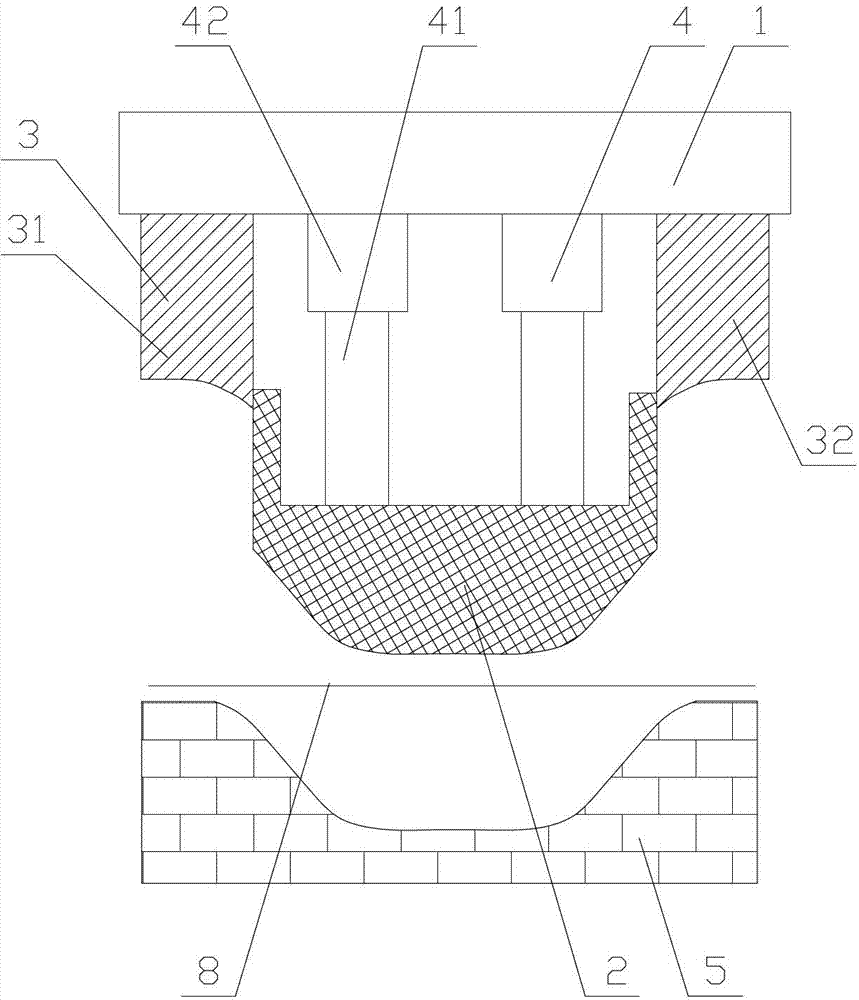

[0031] Integral press split molding equipment, such as Figure 1 to Figure 6 Shown, comprise press platform 1, first press mold 2, back press mold 3 and lower mold 5, described back press mold 3 is connected with press platform 1, first press mold 2 is equipped with adjustable elastic force device 4, can Adjusting elastic force device 4 is connected with press platform 1.

[0032] First press mold 2 and back press mold 3 are split type, and back press mold 3 comprises left back press mold 31 and right back press mold 32, and first press mold 2 is arranged between left back press mold 31 and right back press mold 32. The pre-pressing die 2 and the post-pressing die 3 are separated at the straight line between the crest and the trough of the corrugated steel plate, which can effectively avoid tensile defects at the corners.

[0033] The adjustable elastic device 4 is an adjustable hydraulic oil cylinder. An overpressure relief valve is installed on the adjustable hydraulic cyl...

Embodiment 2

[0044] Integral press split molding equipment, such as Figure 1 to Figure 6 Shown, comprise press platform 1, first press mold 2, back press mold 3 and lower mold 5, described back press mold 3 is connected with press platform 1, first press mold 2 is equipped with adjustable elastic force device 4, can Adjusting elastic force device 4 is connected with press platform 1.

[0045] First press mold 2 and back press mold 3 are split type, and back press mold 3 comprises left back press mold 31 and right back press mold 32, and first press mold 2 is arranged between left back press mold 31 and right back press mold 32.

[0046] The adjustable elastic device 4 is a telescopic rod adjusting device, which includes a telescopic rod 41 and a telescopic rod locking device 42 . There are four adjustable elastic devices 4, which are evenly distributed between the press platform 1 and the first pressing mold 2.

[0047] The integral press split molding process includes the following steps...

Embodiment 3

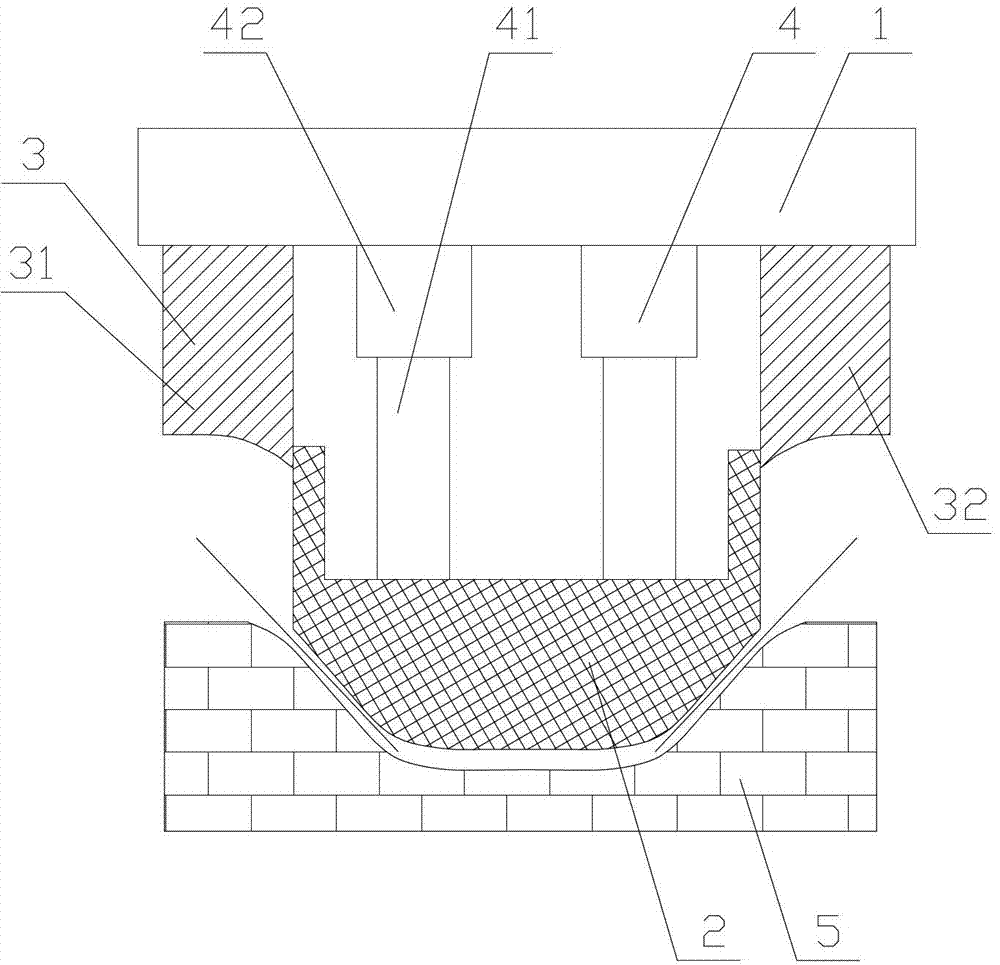

[0057] The difference between this embodiment and Embodiment 1 is that the adjustable elastic device 4 is an adjustable hydraulic cylinder, and the flat steel plate 8 is put into the lower mold 5, and the first pressing mold 2 is pressed down by controlling the adjustable hydraulic cylinder, and the valley steel plate is pressed down. Press into the mold cavity of lower mold 5. At this time, the rear mold has not been pressed down yet, because the two sides are free and unrestricted, so the lower pressure of the first mold is lower; then the press platform 1 drives the rear mold 3 to press down as a whole, and the The steel plate 8 is pressed into a corrugated form, and this process is repeated to press the continuous corrugated steel plate 9.

[0058] In the above process, during the pressing down process of the first pressing mold 2, until the pressing down of the first pressing mold 2 is completed, the oil pressure of the adjustable hydraulic cylinder rises to the set value,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com