Preparation method of high-temperature calcium-based CO2 absorbing material

An absorption material, calcium-based technology, which is applied in the field of preparation of high-temperature calcium-based CO2 absorption materials, can solve problems that have not yet been seen, and achieve the effects of reducing emissions, simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First, the red mud and egg shells were ball-milled in a ball mill for 2 hours, and then passed through a 40-mesh sieve, and then the ground red mud and citric acid with a mass concentration of 8wt% were mixed according to the liquid-solid ratio (mL / g) of 60:1. The solution was acid leached at 40°C for 4 hours. The red mud after acid leaching was washed with deionized water and mixed with egg shells calcined at 900°C. The mass of red mud accounted for 10wt%, and then the mixture was placed in a mortar and added with water. Grind until fully mixed, and then dry at 80°C for 2 hours to obtain high-temperature calcium-based CO 2 absorbent material.

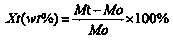

[0025] For the above high temperature calcium-based CO 2 When the absorption material is tested for its adsorption capacity, it goes through the following steps: the high-temperature calcium-based CO 2The absorbing material was placed in a thermogravimetric analyzer, under N 2 In the atmosphere, the temperature was raised to ...

Embodiment 2

[0027] Referring to Example 1, the difference is that when red mud is mixed with egg shells, the mass of red mud accounts for 15wt%, and the measured CO 2 The absorption capacity is 26.24%.

Embodiment 3

[0029] With reference to example 1, difference is that the mass concentration of citric acid solution is 14wt%, measures CO 2 The absorption capacity is 27.07%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com