Rolling bearing device for wheel

A technology for rolling bearings and wheels, which is applied in the directions of wheel bearings, rolling contact bearings, and rotating bearings, etc. It can solve the problems of insufficient strength of the flange and achieve the effect of weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Modes for carrying out the invention will be described based on the embodiments.

[0031] will be based on Figure 1 to Figure 9 Embodiments of the present invention will be described.

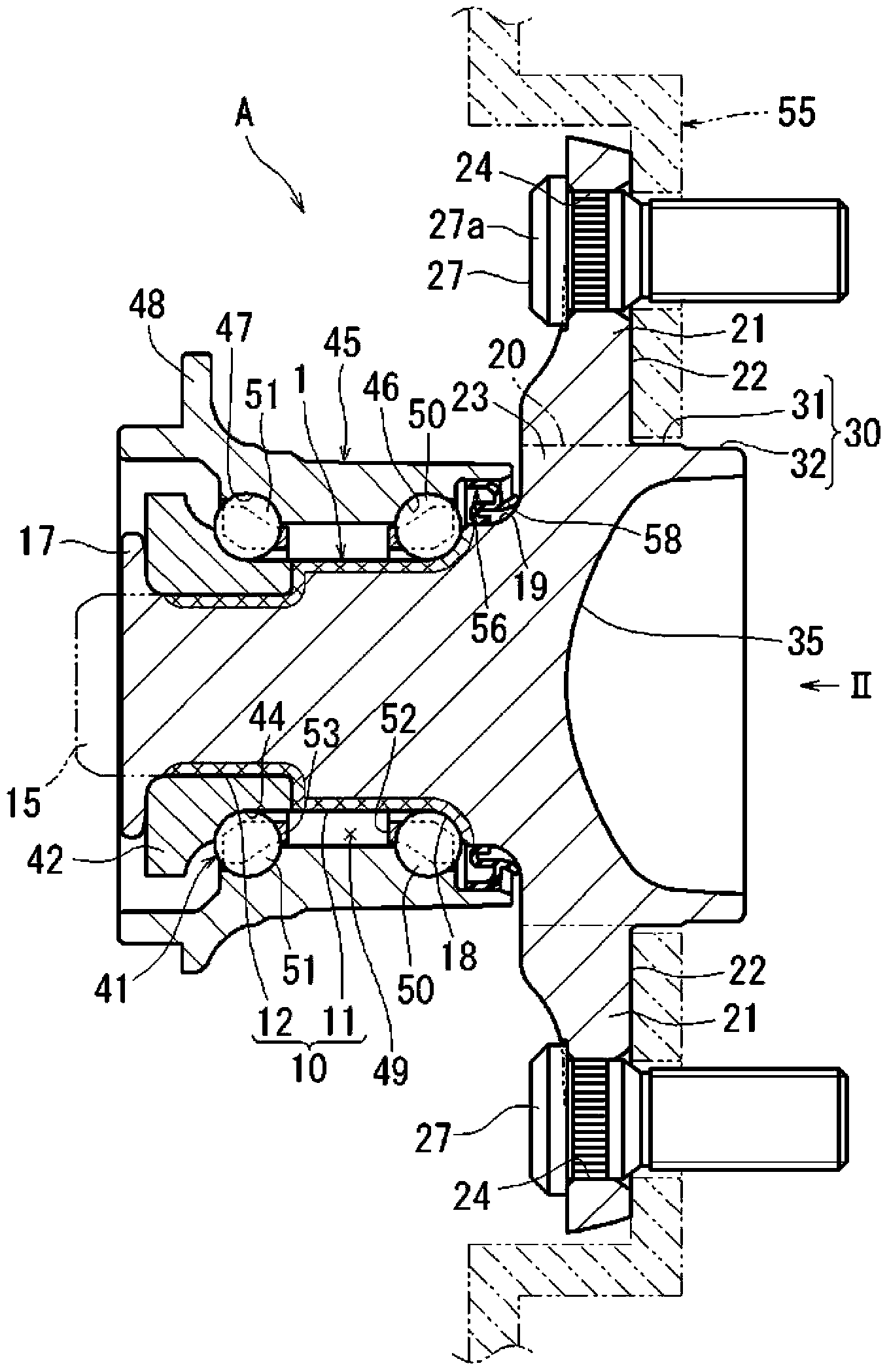

[0032] Such as figure 1 As shown, the hub unit as the rolling bearing device for the wheel A is formed as a unit including the double row angular contact ball bearing 41 and the shaft member 1 of the rolling bearing device A integrally.

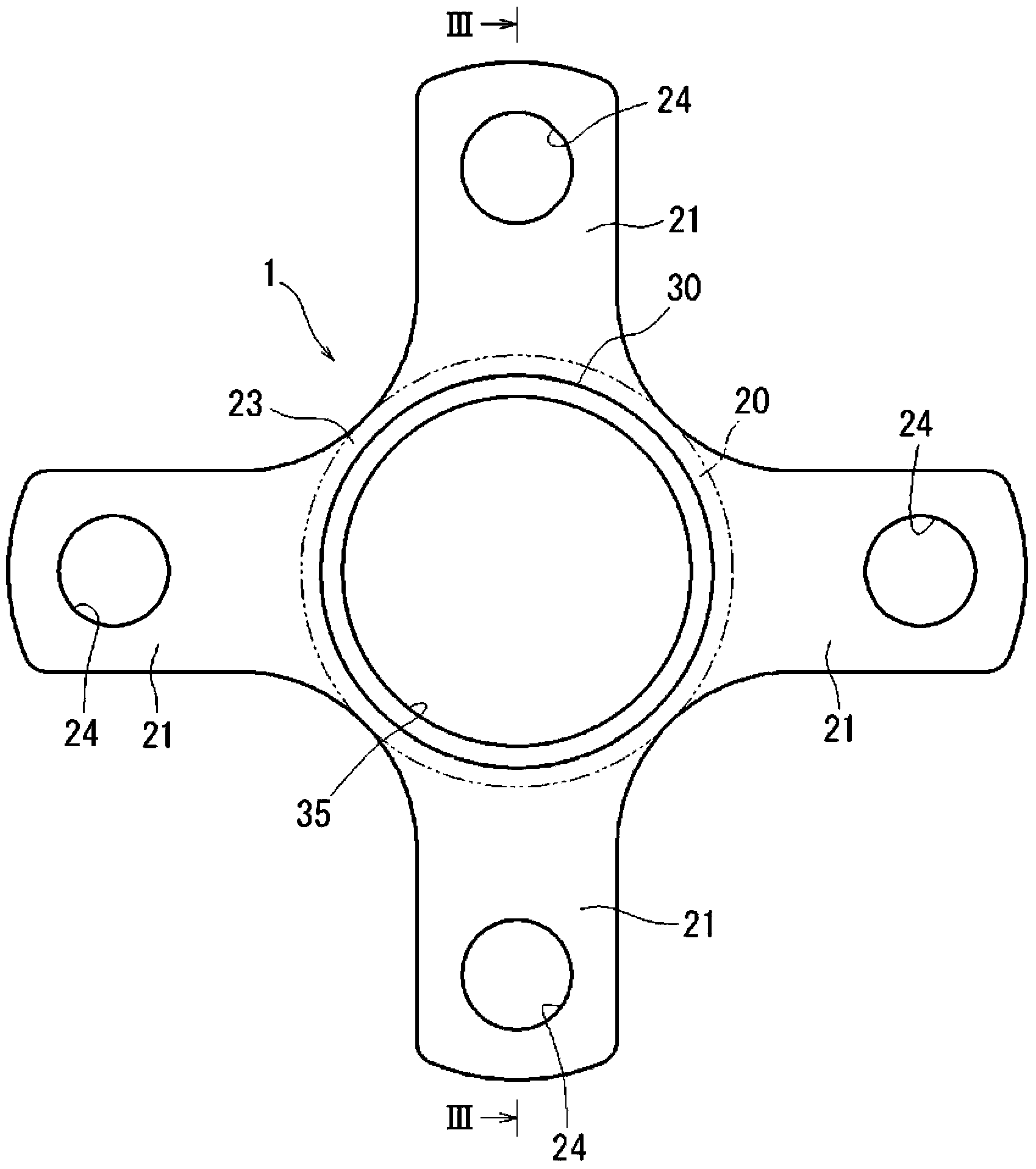

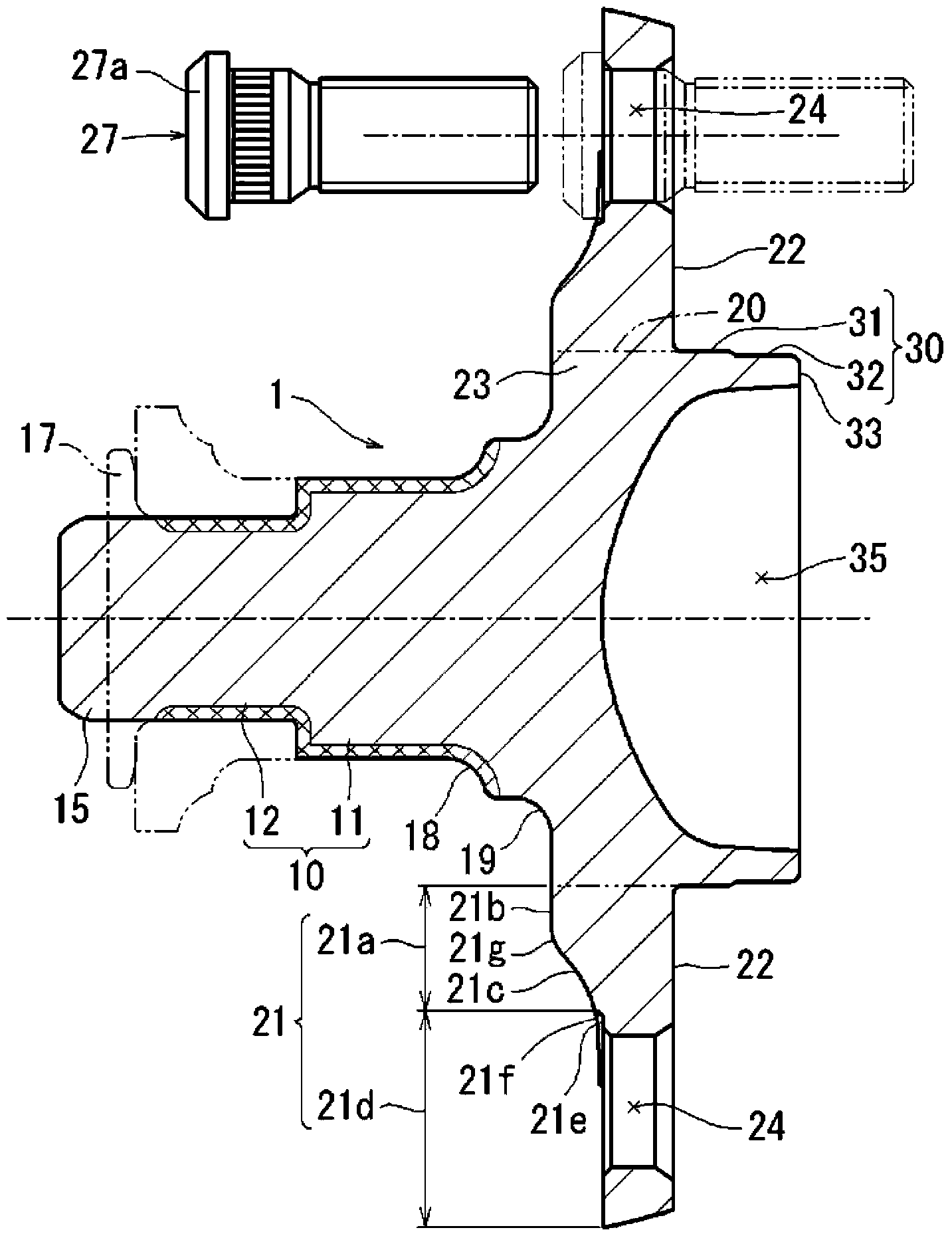

[0033] The shaft member 1 of the rolling bearing device A integrally includes: a shaft portion 10; a fitting shaft portion 30 formed at one end portion of the shaft portion 10, the fitting shaft portion 30 having a a larger diameter and a central hole for fitting a wheel (not shown) on the fitting shaft portion 30; a flange base 23 positioned between the shaft portion 10 and the fitting shaft portion 30; and a plurality of flange portions 21 provided on the outer circumferential surface of the flange base portion 23 to extend radially outward in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com