Manufacturing method of deep sea watertight electric connector

A manufacturing method and connector technology, applied in connection, circuit/collector parts, circuits, etc., can solve the problems of incomplete sealing, unusable, easy water seepage, etc., and achieve reliable sealing performance and avoid incomplete sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

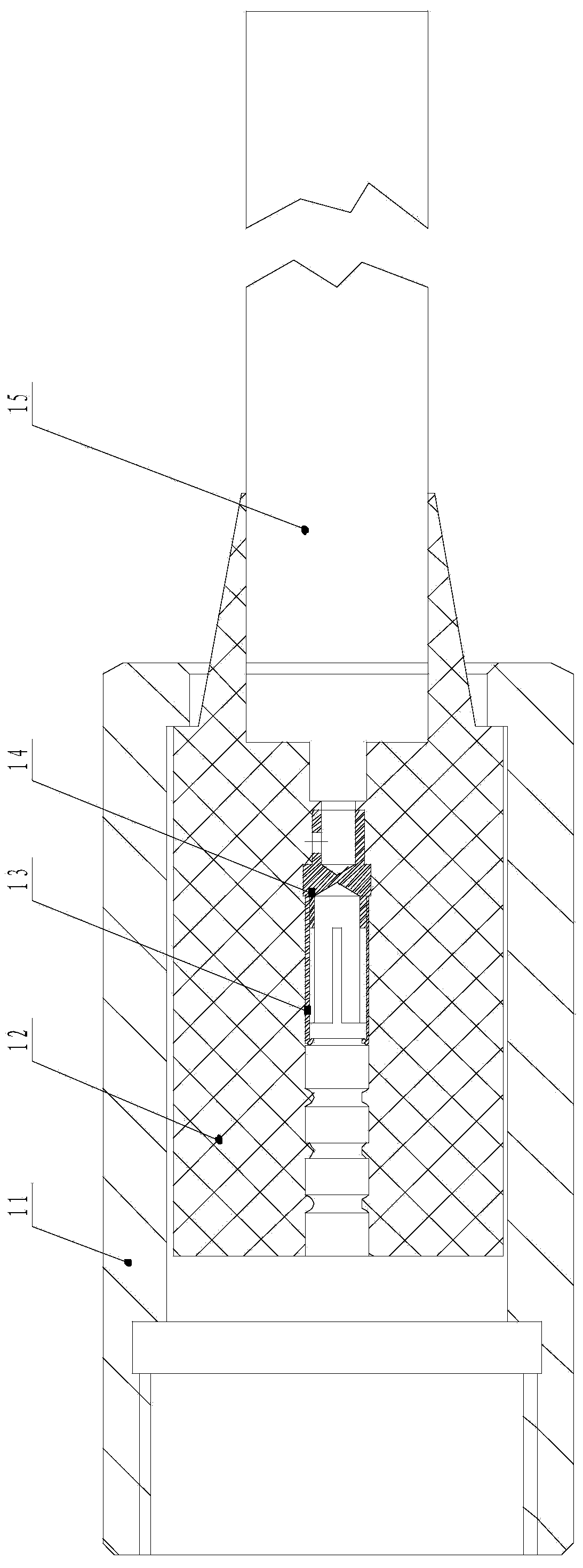

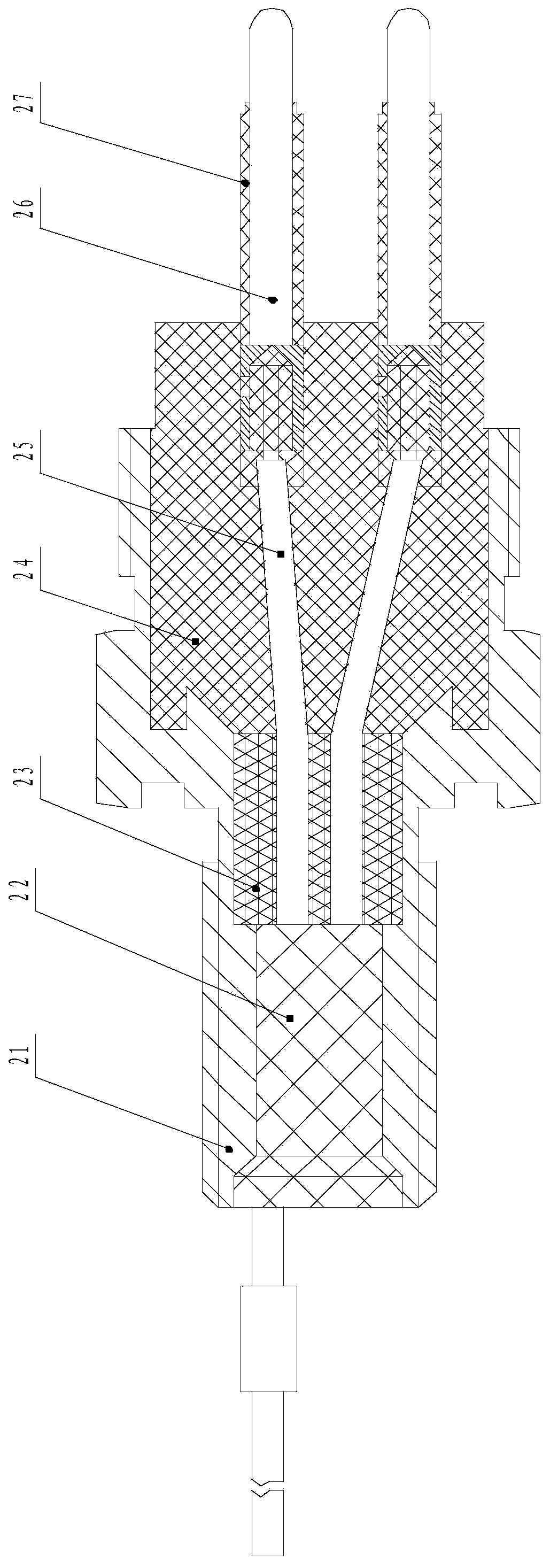

[0032] The present invention will be further described below in conjunction with accompanying drawing:

[0033] Prepare the mold for the vulcanization process, Chemlok activator and R4 metal binder, both of which are commercially available.

[0034] A method for manufacturing a deep-sea watertight electrical connector, the steps of which are:

[0035] 1) The socket 14 and the contact pin 26 are made of beryllium bronze material, and the surface of the socket 14 and the contact pin 26 is electroplated with gold;

[0036] 2) Assemble one end of the jack 14 with the jack sheath 13, and weld the other end with the cable 15; weld the wire 25 passing through the fixing part 23 with the pin 26, and install the fixing part 23 into the shell 21;

[0037] 3) Vulcanization process: when vulcanizing, first preheat at normal pressure for 1-2 minutes, adjust the pressure to 1.8-2.5Mpa and continue preheating for 1-2 minutes, so that the temperature of the mold is controlled at 170 ° C ~ 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com