Single-ended halogen lamp with supporting frame locating hook

A support frame and positioning hook technology, applied in the direction of the fixture/support of the luminous body, can solve the problems of uneven distribution of single-ended halogen lights, affecting the quality of single-ended halogen lamps, and unattractive appearance of single-ended halogen lamps , to achieve the effect of long service life, high quality consistency and stable manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

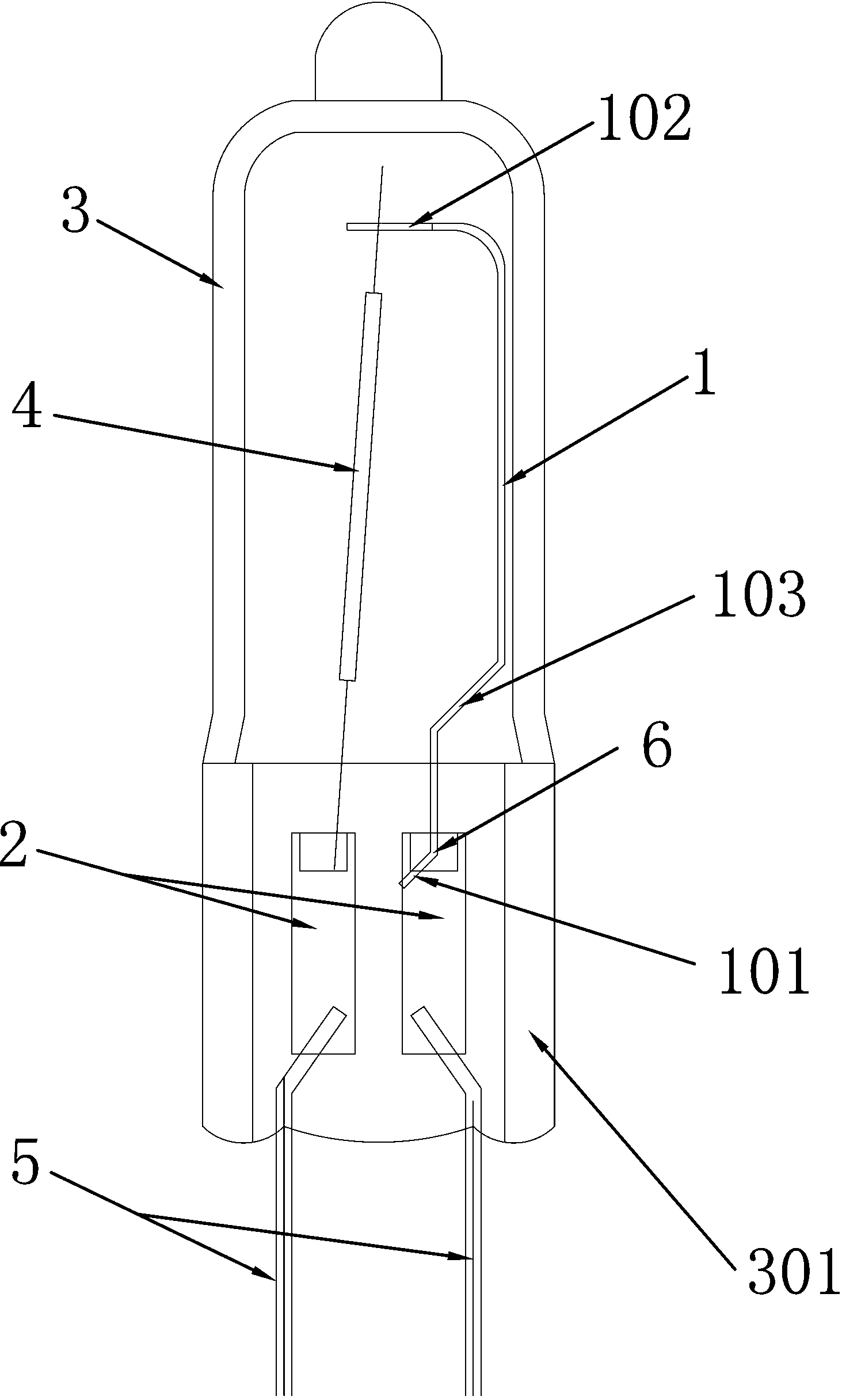

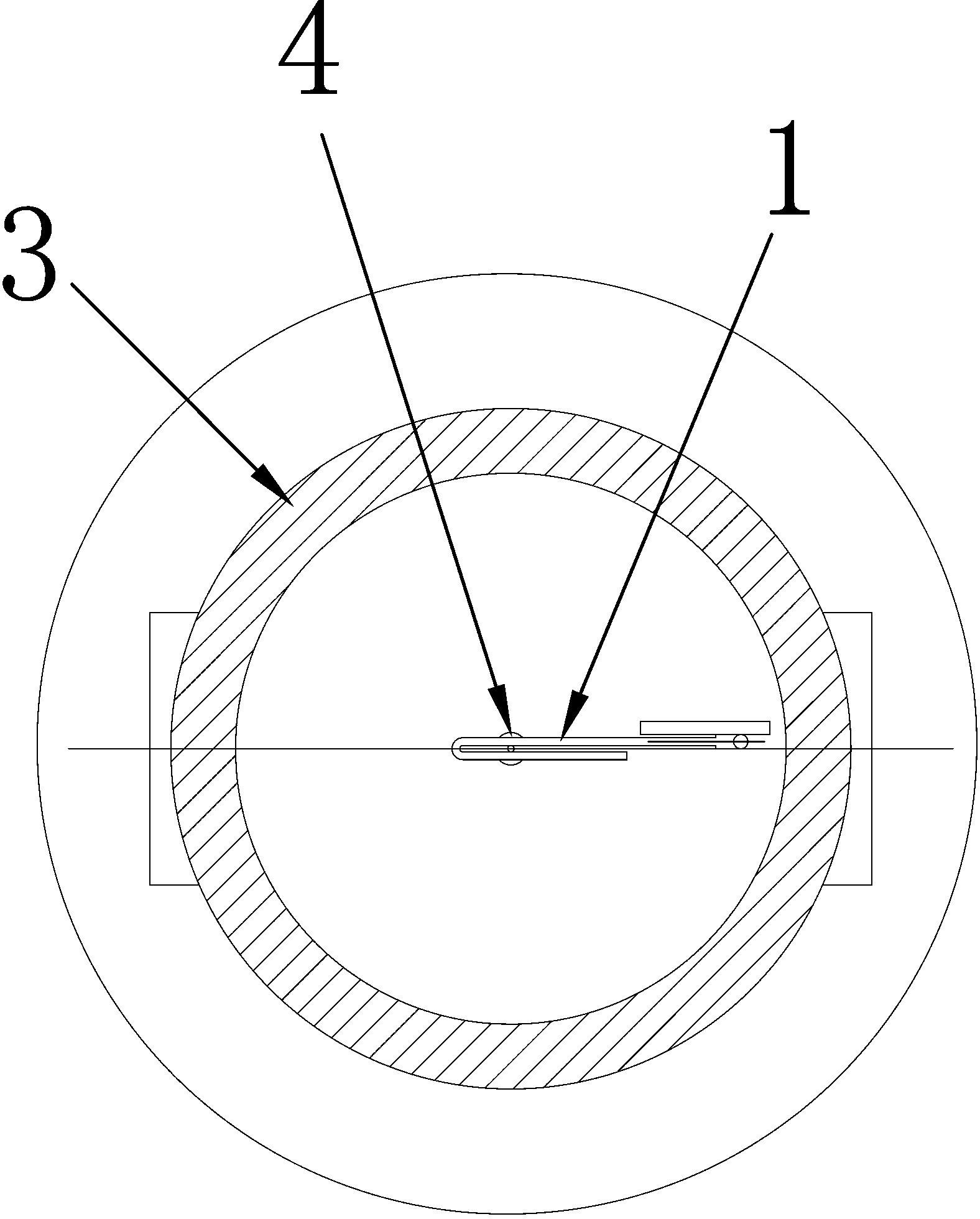

[0015] Example 1: See attached figure 1 Attached Figure 4 As shown, the single-ended halogen lamp with the positioning hook of the support frame described in this embodiment is mainly a 110-120V single-ended halogen lamp, which includes a filament support frame 1, a molybdenum sheet 2 spot-welded with feet 5, and a bulb Shell 3, filament 4, wherein the filament support frame 1, the molybdenum sheet 2, and the filament 4 are respectively placed in the bulb 3, and the molybdenum sheet 2 has two pieces located in the flat position 301 of the bulb 3 with a width In the middle part, the legs 5 of the two molybdenum sheets 2 respectively extend out of the bulb 3 for connecting the positive and negative electrodes of the power source; one end of the filament support frame 1 is bent along the width direction of the bulb 3 to form a The filament hook 102 supporting the filament 4, one end of the filament 4 is hung on the filament hook 102, the filament hook 102 clamps the filament 4, t...

Embodiment 2

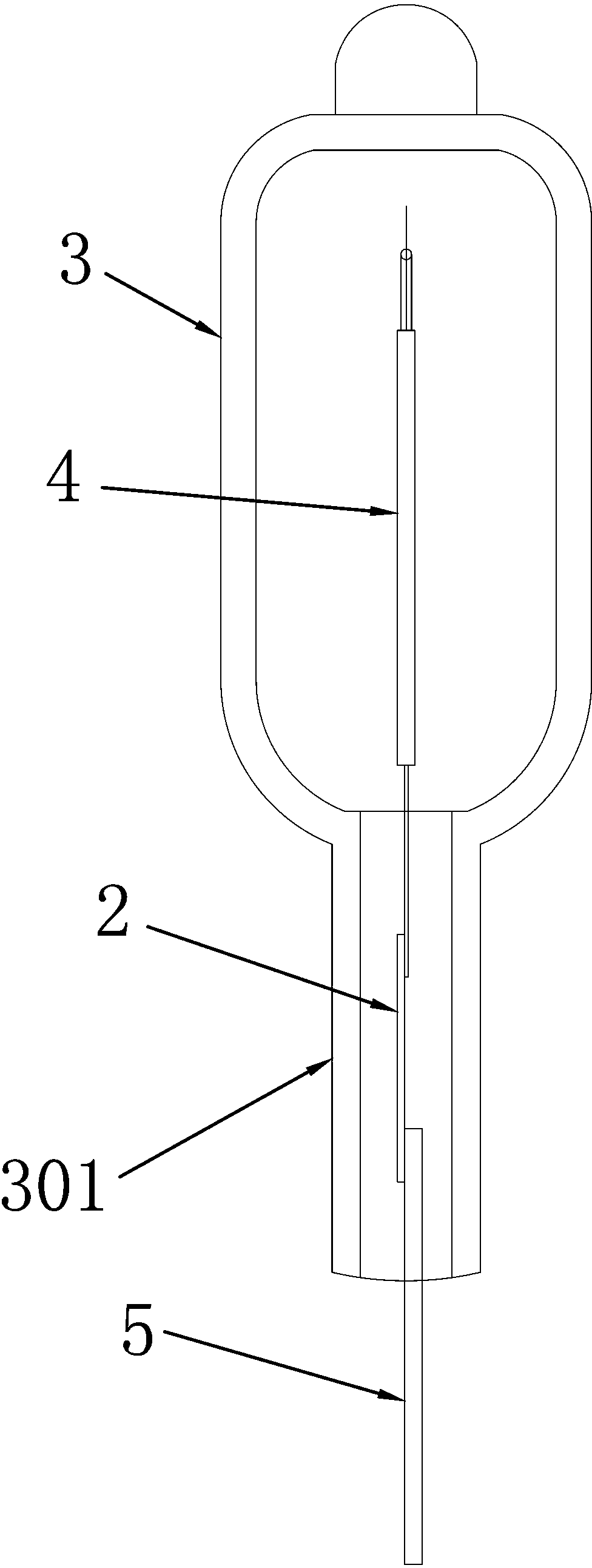

[0016] Example 2: See attached Figure 5 As shown, the difference from embodiment 1 is that the two molybdenum sheets 2 located in the clamping flat position 301 in this embodiment are located on one side of the width of the clamping flat position 301, and the welding place 6 between the filament support frame 1 and the molybdenum sheet 2 There is no bending part 103 formed above, but this embodiment can also achieve the effect described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com