Manufacturing method of hydrogen oxygen fuel cell display plate type teaching aid

A fuel cell and manufacturing method technology, which can be applied to educational appliances, teaching models, instruments, etc., can solve the problems of inconvenient experimental operation, unfavorable working principle of the fuel cell, and the assembly of the experimental device is not simple enough, so as to enhance persuasion and interest. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

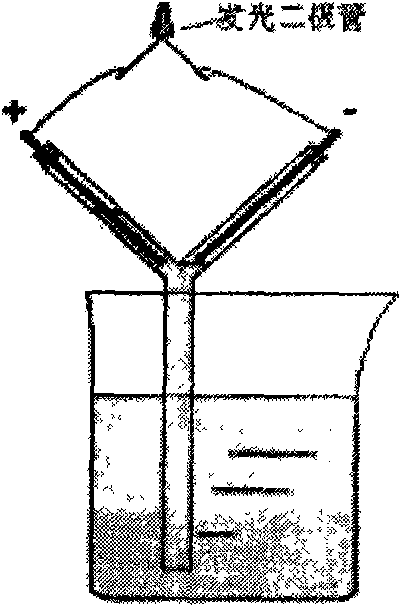

[0014] A method for manufacturing a hydrogen-oxygen fuel cell display board teaching aid, comprising the following steps:

[0015] 1. Preparation of experimental supplies: small beaker, Y-shaped tube, graphite electrode, single-hole rubber stopper, light-emitting diode, saturated Na 2 SO 4 Solution, DC power supply, wire;

[0016] 2. Rubber plugs with graphite electrodes on the two plugs of the Y-shaped tube are sealed;

[0017] 3. Inject saturated Na into the Y-shaped tube 2 SO 4 Solution, after exhausting the air, submerge the open end into the saturated Na in the beaker 2 SO 4 in solution;

[0018] 4. Turn on the DC power supply and start electrolysis;

[0019] 5. When the amount of gas generated by electrolysis exceeds the length of the graphite electrode, the electrolysis of water will automatically stop;

[0020] 6. Connect the light-emitting diodes with wires to form a fuel cell, and observe the light-emitting diodes to complete the production of hydrogen-oxygen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com