Installing structure and installing method for touch screen and liquid crystal screen of train vehicle-mounted display

A vehicle-mounted display and installation structure technology, applied in the input/output process of instruments, data processing, optics, etc., can solve the problems of touch screen function impact, interference, touch screen shaking, etc., meet the requirements of electromagnetic compatibility and reduce the probability of displacement , The effect of improving the response accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

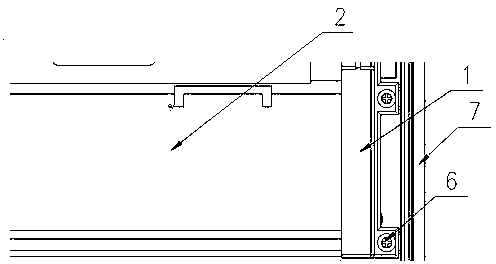

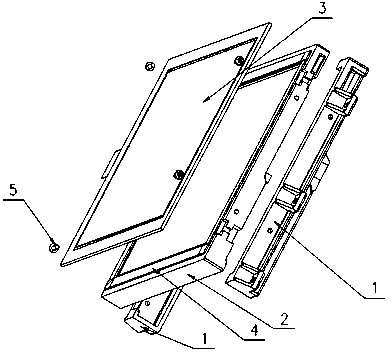

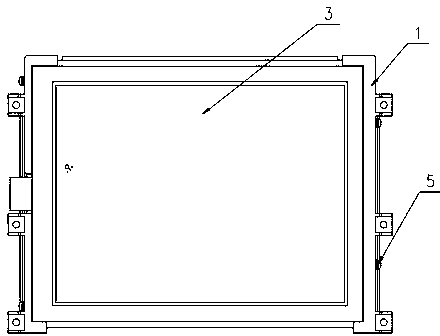

[0041] Such as Figure 1 to Figure 4As shown, the installation structure of the touch screen and liquid crystal screen of the on-board display of the train includes a touch screen 3, a liquid crystal screen 2, a display screen front shell 7, a screen installation assembly 1, a double-sided adhesive liquid crystal screen rubber pad 4 and a single-sided attached glued touch screen rubber pad 8; the screen mounting assembly 1 is provided with reinforcing ribs and adopts high-strength materials, and the screen mounting assembly 1 is installed on both sides of the liquid crystal screen 2 through the first screw 5 in a socketed manner, and the liquid crystal screen rubber pad 4 is pasted On the edge around the front of the LCD screen 2; the touch screen 3 is located in front of the LCD screen 2 and pasted on the rubber pad of the LCD screen, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com