Large environment simulation test device for pipeline ball valve test

An environmental simulation test and environmental simulation technology, applied in the field of large-scale environmental simulation test devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] Please refer to the accompanying drawings for a further description of the present invention.

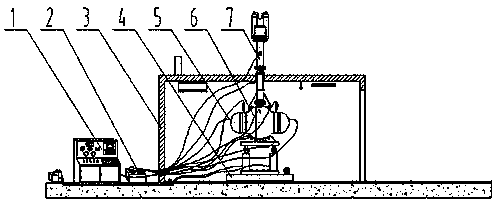

[0060] Such as figure 1 As shown, the present invention provides a kind of NPS2~NPS60, Class150~Class2500 pipeline ball valve, the test temperature is -50 ℃~+93 ℃ large-scale environmental simulation test device for pipeline ball valve test, including pressure supply system 1, data processing system 2 , environmental simulation chamber 3, test lifting platform 4, temperature sensor 5, tested pipeline ball valve 6, torque measuring device 7.

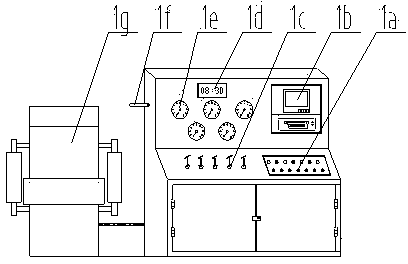

[0061] Such as figure 2 As shown, the pressure supply system 1 includes an operation button 1a, a touch screen data recording system 1b, a control valve 1c, a pressure dwell time alarm 1d, a pressure gauge 1e, an air source interface 1f, and a hydraulic pressure boosting system 1g, mainly for the tested pipeline ball valve 6 Provide test pressure, and can conduct shell test, high-pressure sealing test and low-pressure sealing test for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com