Method for measuring pressure of constant-volume quick inflation/deflation air cavity

A gas pressure and pressure technology, which is applied in the field of gas pressure measurement, can solve problems such as inaccurate pressure measurement, and achieve the effect of improving measurement accuracy and detection result accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

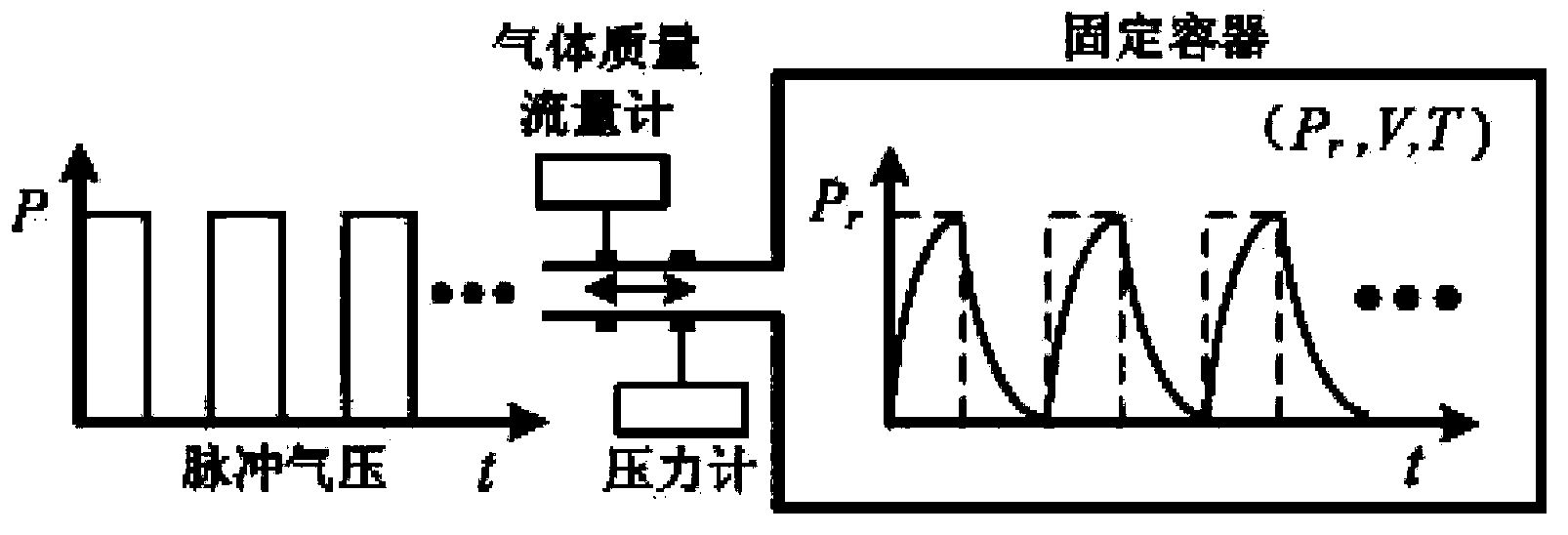

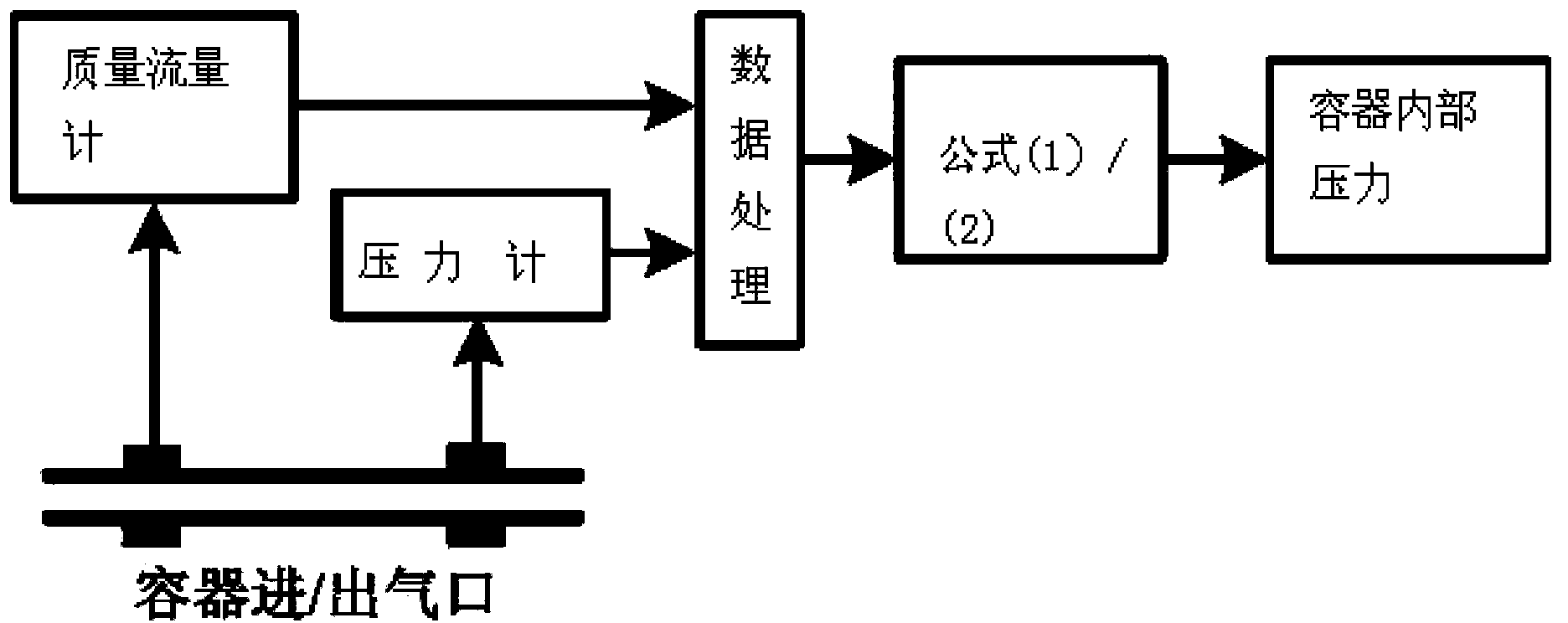

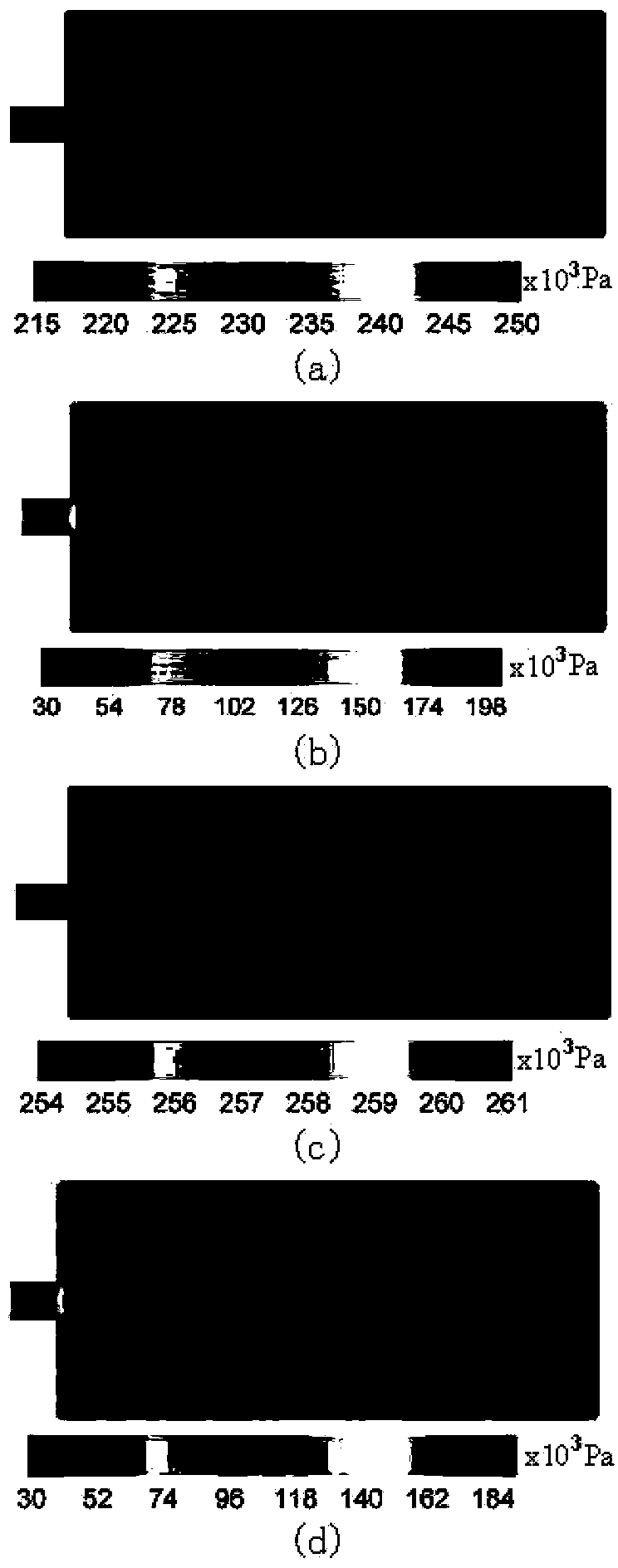

[0040] As mentioned above, since there is currently no sensor that can directly and effectively measure the instantaneous pressure inside the sealed volume, it is difficult to directly obtain the real pressure value in the container. The internal pressure P of the container during the deflation process M (theoretical pressure), container inlet / outlet gas mass flow Q, container inlet / outlet pressure P a Three important parameters (standard theoretical values), the Q, P a Substituting calculation formulas (1) and (2) to calculate the instantaneous pressure value P inside the container obtained by the present invention r , and further compare P M ,P a ,P r The relationship between the three, thereby verifying the necessity and effectiveness of the present invention.

[0041] Firstly, the computational fluid dynamics simulation software FLUENT is used to numerically simulate the constant volume pulse charging and deflation process. A cylindrical vessel with a diameter of 30m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com