Wheel-rail force strain gage fast and precise positioning device

A technology of precise positioning and positioning device, used in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of low paste efficiency and low position accuracy, achieve precise position, easy and fast paste, and improve work efficiency and the effect of the accuracy of the test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structure of the present invention will be described in further detail below in conjunction with the accompanying drawings.

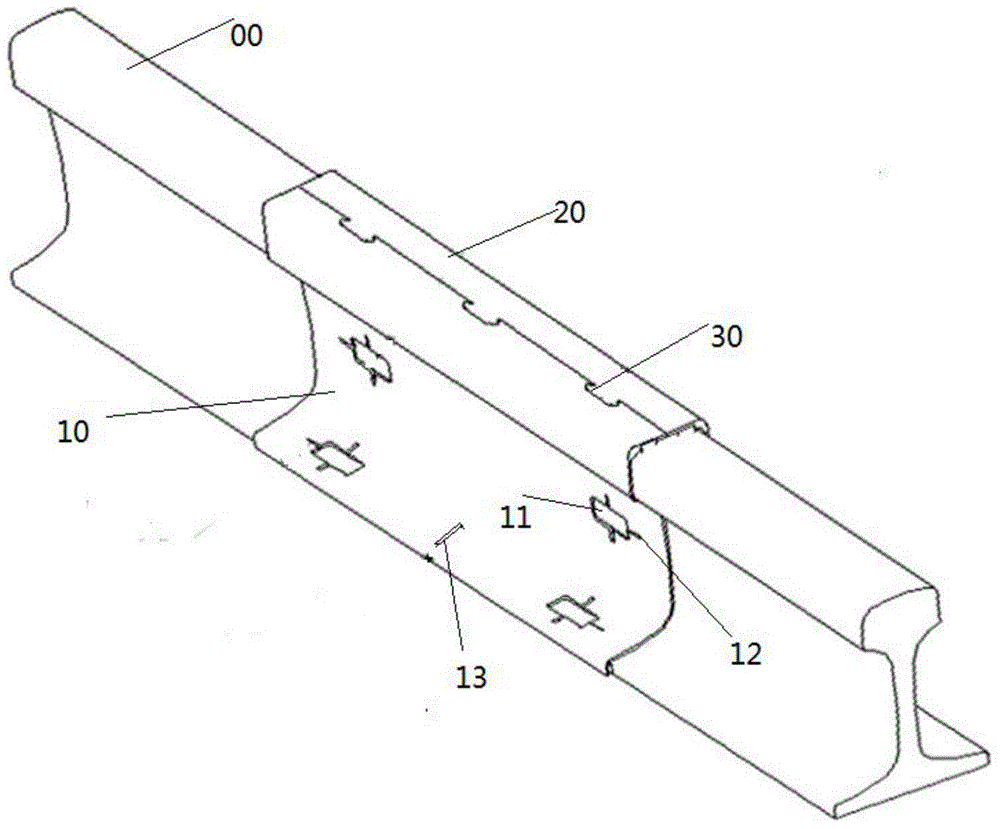

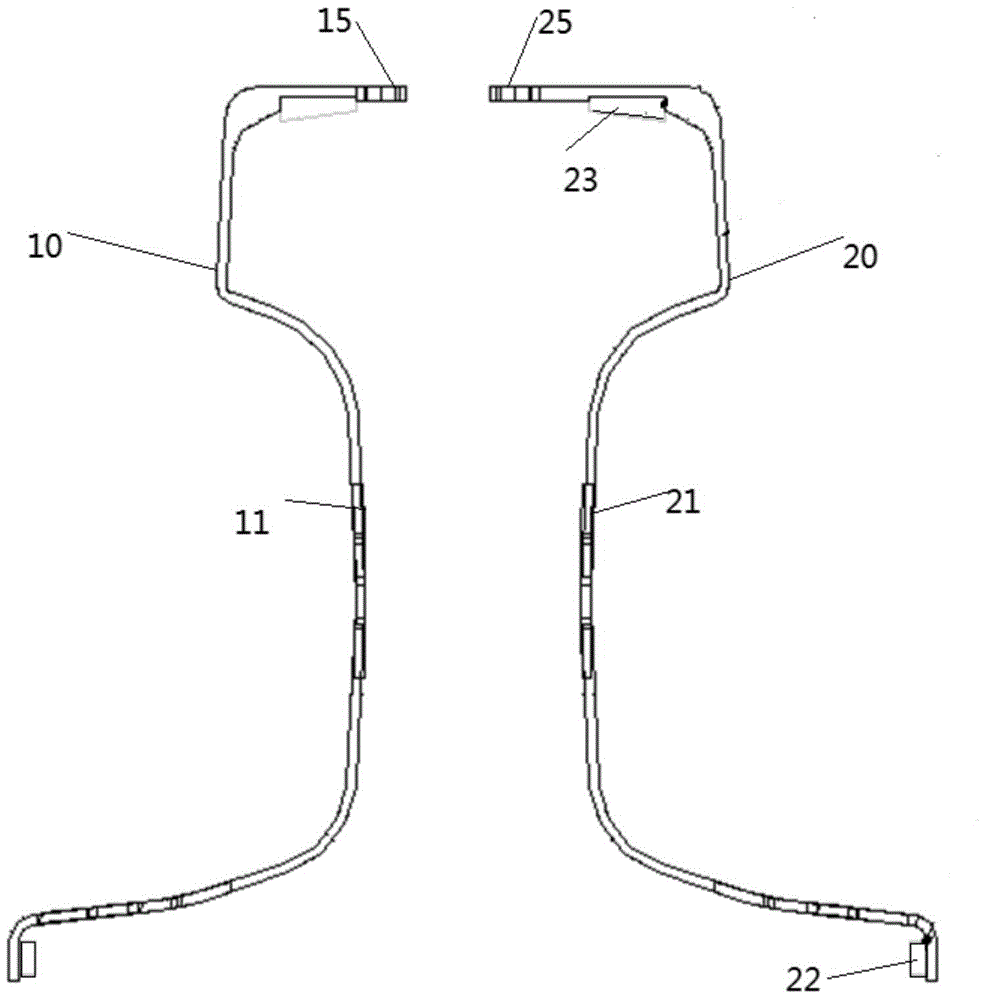

[0014] It can be seen from the figure that the positioning device is composed of two mirror-symmetric calibration plates, that is, a left calibration plate 10 and a right calibration plate 20 . The calibration plate has a shape consistent with the rail waist and rail bottom of the tested wheel and rail 00. Calibration holes, such as 11 and 21, are set on the calibration plate corresponding to the tested wheel-rail waist and rail bottom items, and the calibration holes can be set in multiple places as required. The middle part of the bottom surface of the calibration plate is provided with a centering hole 13 for observing and positioning to realize the correct placement of the calibration plate. The tops of the left calibration plate 10 and the right calibration plate 20 are provided with a buckle mechanism 30 to realize the coupling of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com