contact stress sensor

A contact stress and sensor technology, applied in the field of sensors, can solve the problems of small thickness of foil strain gauges, complicated processes, poor temperature characteristics of devices, etc., and achieve the effects of easy popularization and use, obvious changes in length, and obvious changes in resistance value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

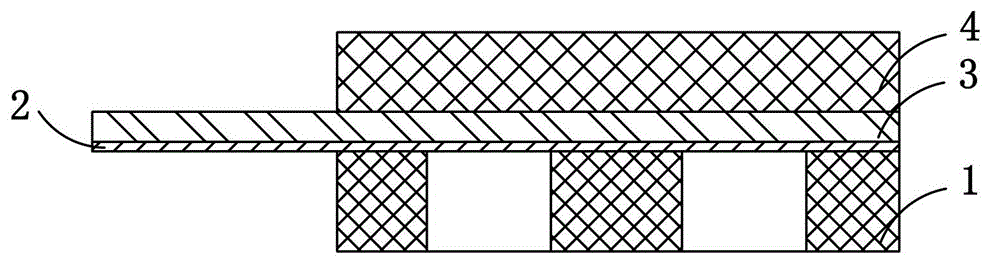

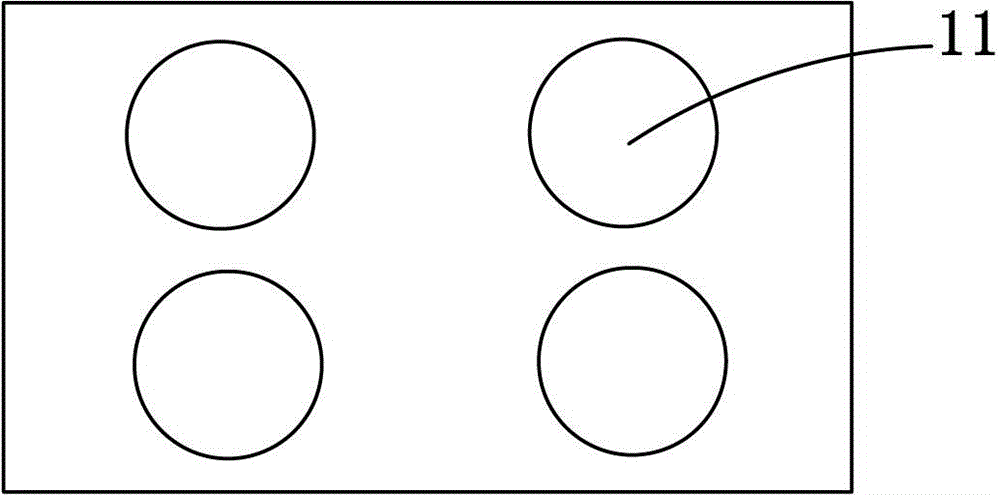

[0025] Such as figure 1 , figure 2 As shown, the contact stress sensor in this embodiment includes a flexible support base 1 with four circular through holes 11, a strain gauge 2, a flexible transmission line 3 and a flexible medium 4, wherein the flexible support base 1 is located at the bottom, and the strain The meter 2 and the flexible transmission line 3 are connected as a whole by wire bonding and then bonded to the upper surface of the flexible support base 1 by AB glue. Four circular through-holes 11 are also the main structure that enables the contact stress sensor in this embodiment to be used for contact stress monitoring. Due to the existence of these holes, under the action of force, the strain gauge 2 on the flexible support base 1 Simultaneous bending and deformation of multiple parts corresponding to the position of the through hole 11 makes the length change of the sensitive grid in the strain gauge 2 more obvious in a smaller thickness range, that is, the c...

Embodiment 2

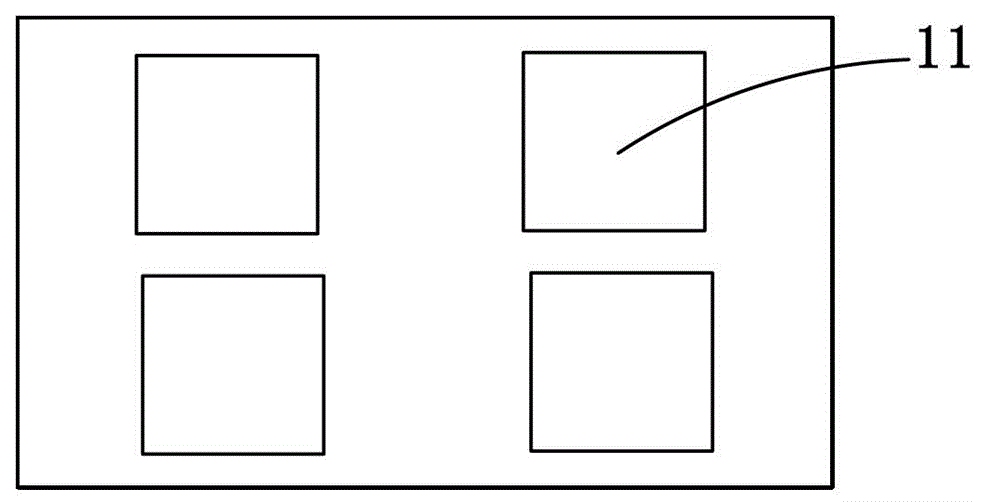

[0030] The structure and working principle of the contact stress sensor in this embodiment are the same as that of the contact stress sensor in Embodiment 1, the difference is that four square through holes 11 are arranged on the flexible support base plate in this embodiment; The material of the flexible support substrate 1 of the contact stress sensor is polyimide with an elastic modulus of 2.25 GPa, and the material of the flexible medium 4 is rubber with an elastic modulus of 25 MPa.

Embodiment 3

[0032] The structure and working principle of the contact stress sensor in this embodiment are the same as that of the contact stress sensor in Embodiment 1, the difference is that four rectangular through holes 11 are arranged on the flexible support base plate in this embodiment; The material of the flexible support substrate 1 of the contact stress sensor is polyimide with an elastic modulus of 4GPa, and the material of the flexible medium 4 is rubber with an elastic modulus of 50MPa.

[0033] The number of through holes on the flexible support base in the above embodiments is not limited to four.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com