Optical fiber sensor and method for measuring multiple parameters of air compressor fluid

A compressor and multi-parameter technology, applied in the direction of liquid/fluid solid measurement, measurement flow/mass flow, measurement devices, etc., can solve the problems of slow response speed of flow sensor, poor mechanical strength of optical fiber, measurement value error, etc., and achieve weight Lightweight, improved precision, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Describe the present invention below in conjunction with specific embodiment:

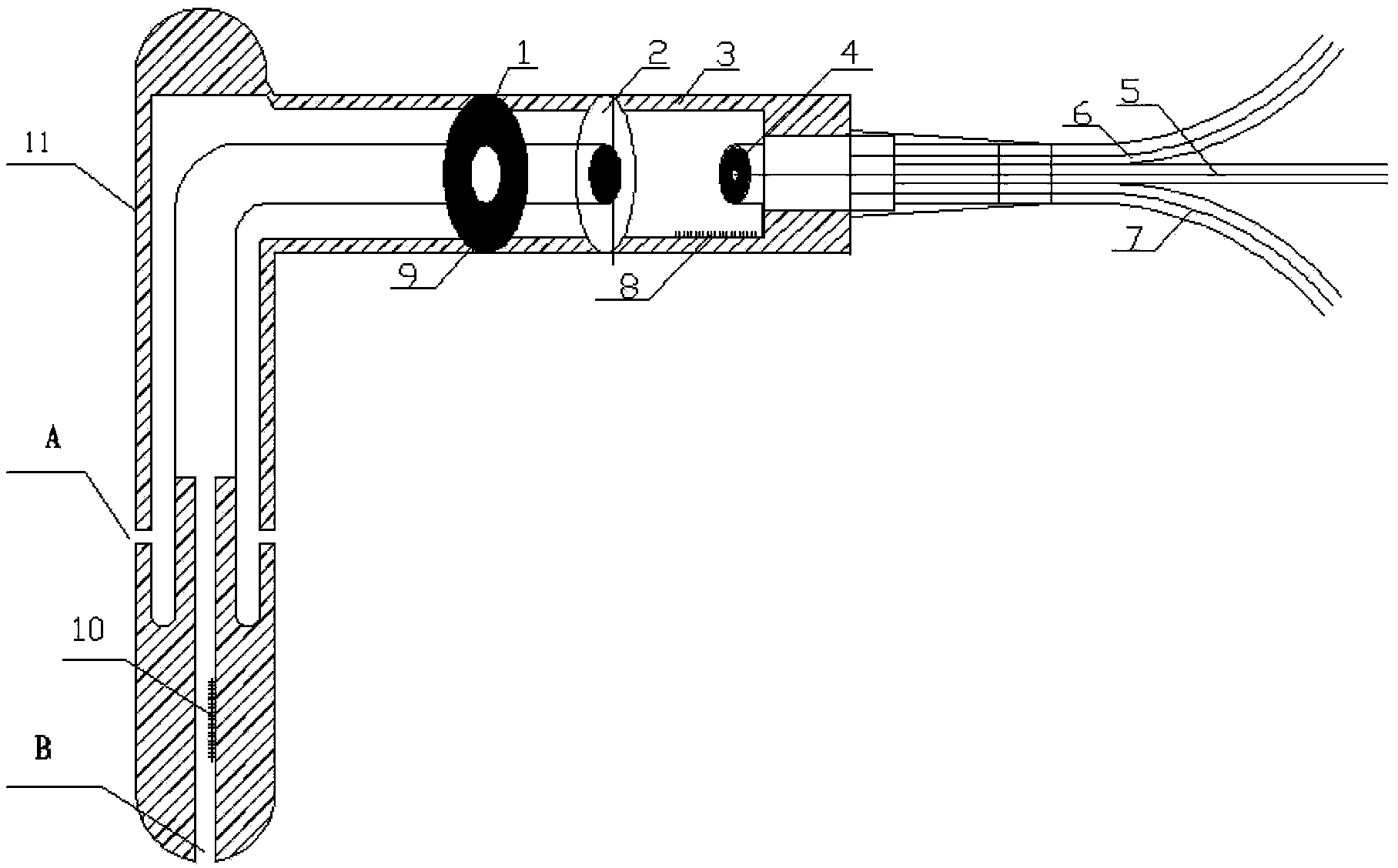

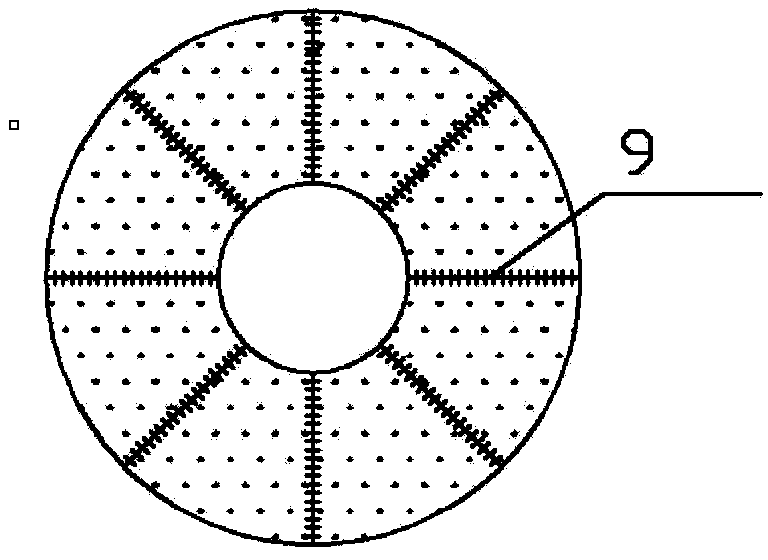

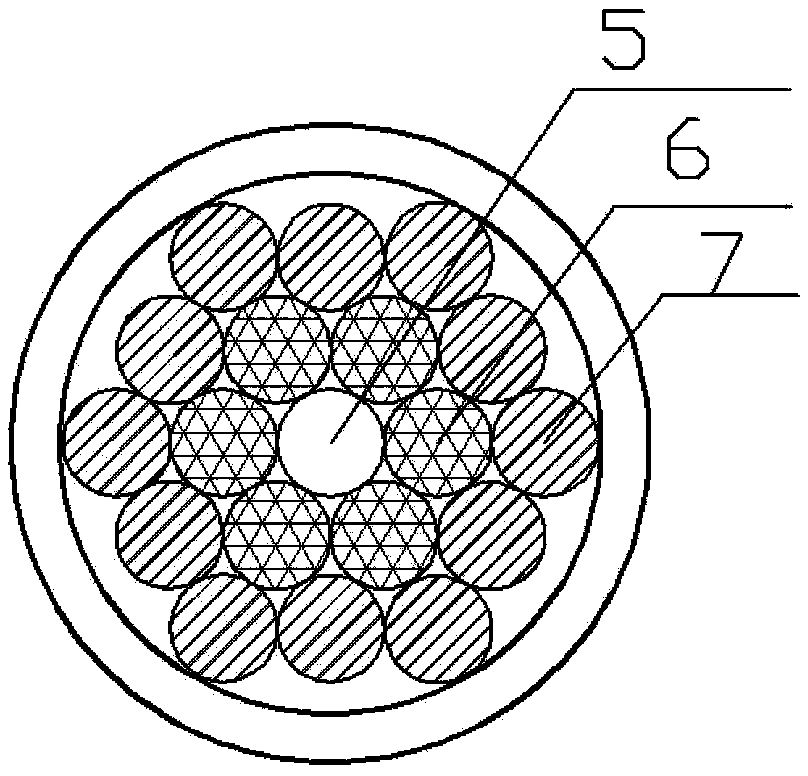

[0032] Refer to attached figure 1 , a light intensity type and grating type hybrid optical fiber sensor for multi-parameter measurement of compressor fluid in the present embodiment includes a pitot tube 11; it is characterized in that: it includes an annular static pressure elastic strain gauge 1, a circular total pressure elastic strain gauge Sheet 2, cylindrical metal package shell 3, double-circle coaxial light intensity reflection fiber probe 4, temperature measuring grating optical fiber 8 and temperature measuring grating optical fiber 10; cylindrical metal package shell 3 is connected to the measurement interface of pitot tube 11, and An annular static pressure elastic strain gauge 1 with a through hole in the center is set at the connection between the cylindrical metal package shell 3 and the Pitot tube 11, and a through hole is provided at the other end of the cylindrical metal pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com