Military extra-high-pressure oxygen valve

An oxygen valve and high-pressure technology, applied in the field of oxygen valves, can solve problems such as poor sealing effect and achieve excellent sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the drawings and specific embodiments.

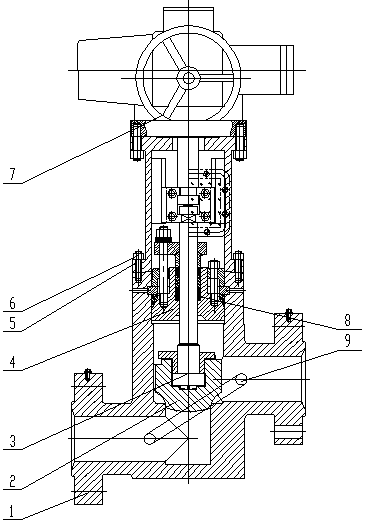

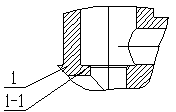

[0017] Reference figure 1 with figure 2 , 3 , A military-industrial very high-pressure oxygen valve, including a sealing structure between the valve body, valve seat and the valve flap, the sealing structure between the valve body, valve seat and the valve flap is a differential angle seal with an angle difference of 2°~5° Vice; differential angle sealing pair is different from the sealing pair of ordinary valves. The structure is designed based on the comprehensive consideration of sealing effect and reducing sealing force. The sealing pair consists of two sealing surfaces at a certain angle, that is, the angles of the valve body sealing surface 1-1 and the valve flap sealing surface 2-1 are different, and there are always 2°, 3°, 4 between the two sealing surfaces. ° or 5° angle difference. The sealing material is made of MONEL alloy with extremely high f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com