Durability testing device and testing method of solid-liquid two-phase flow pump

A technology of durability test and flow adjustment device, which is applied in the direction of pump control, non-variable pump, machine/engine, etc. It can solve the problem of not considering the influence of temperature on the test bench, not making full use of the sedimentation effect of slurry, and not suitable for Long-term reliability test and other issues, to achieve the effect of light weight, low price and good heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

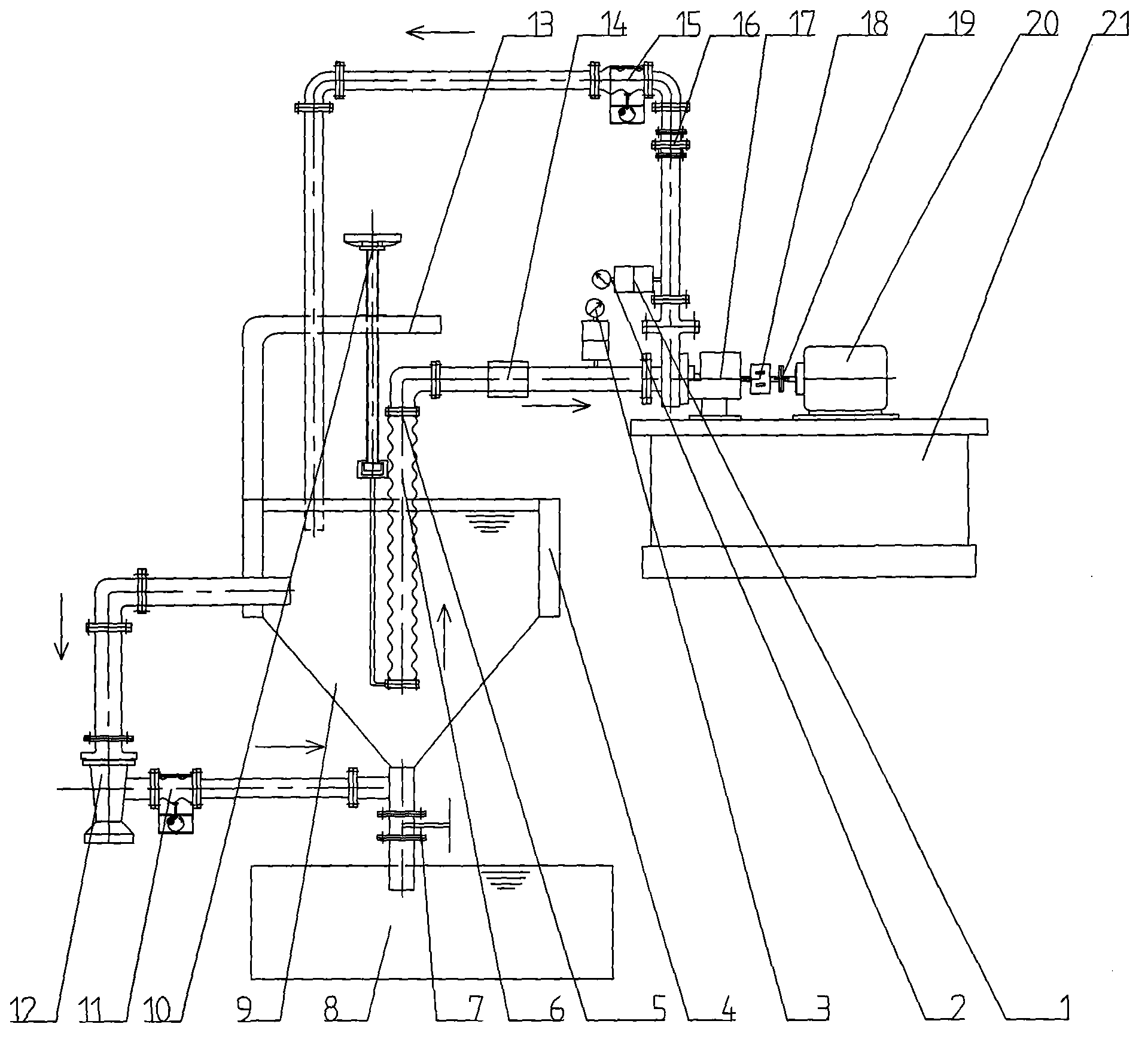

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

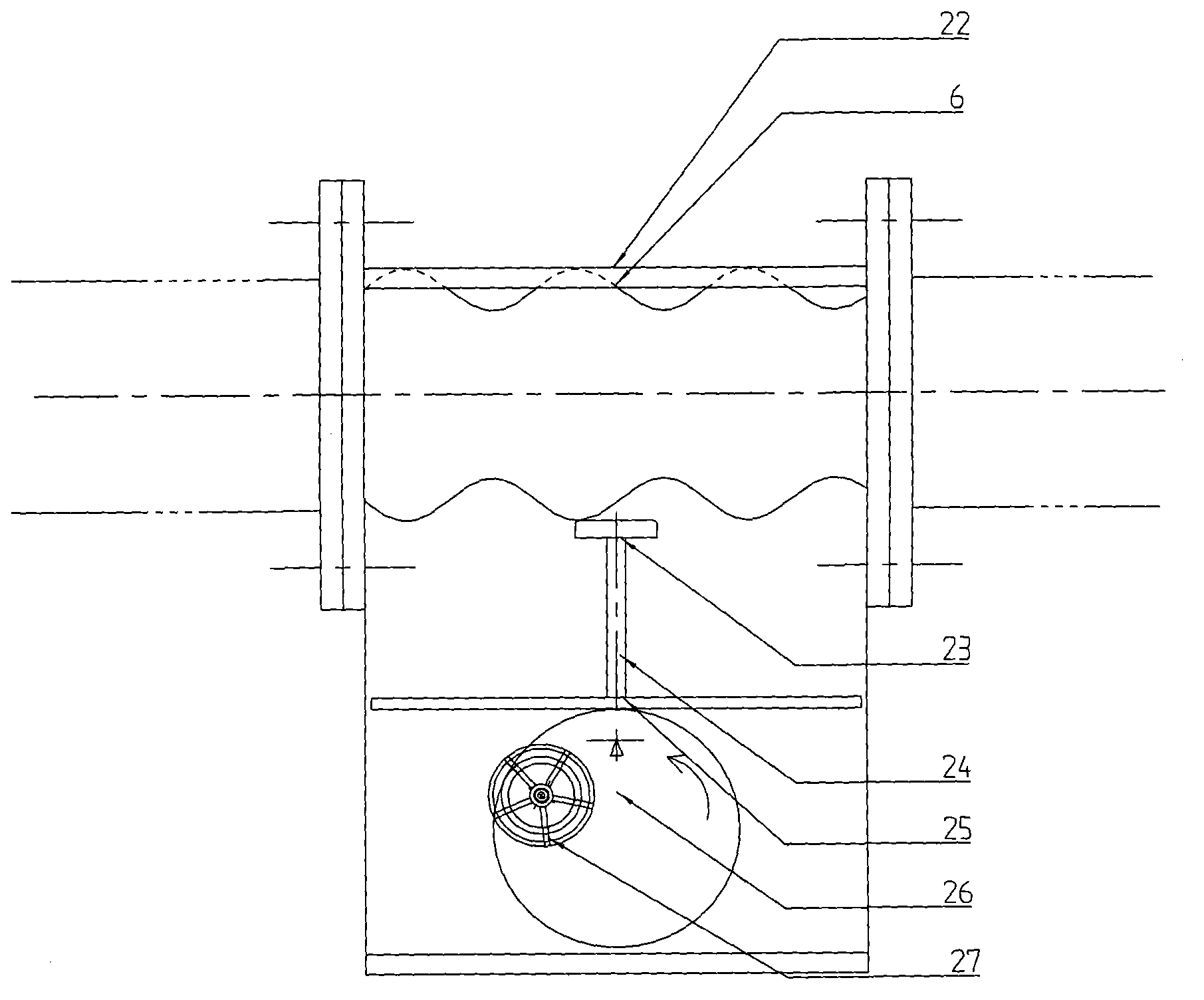

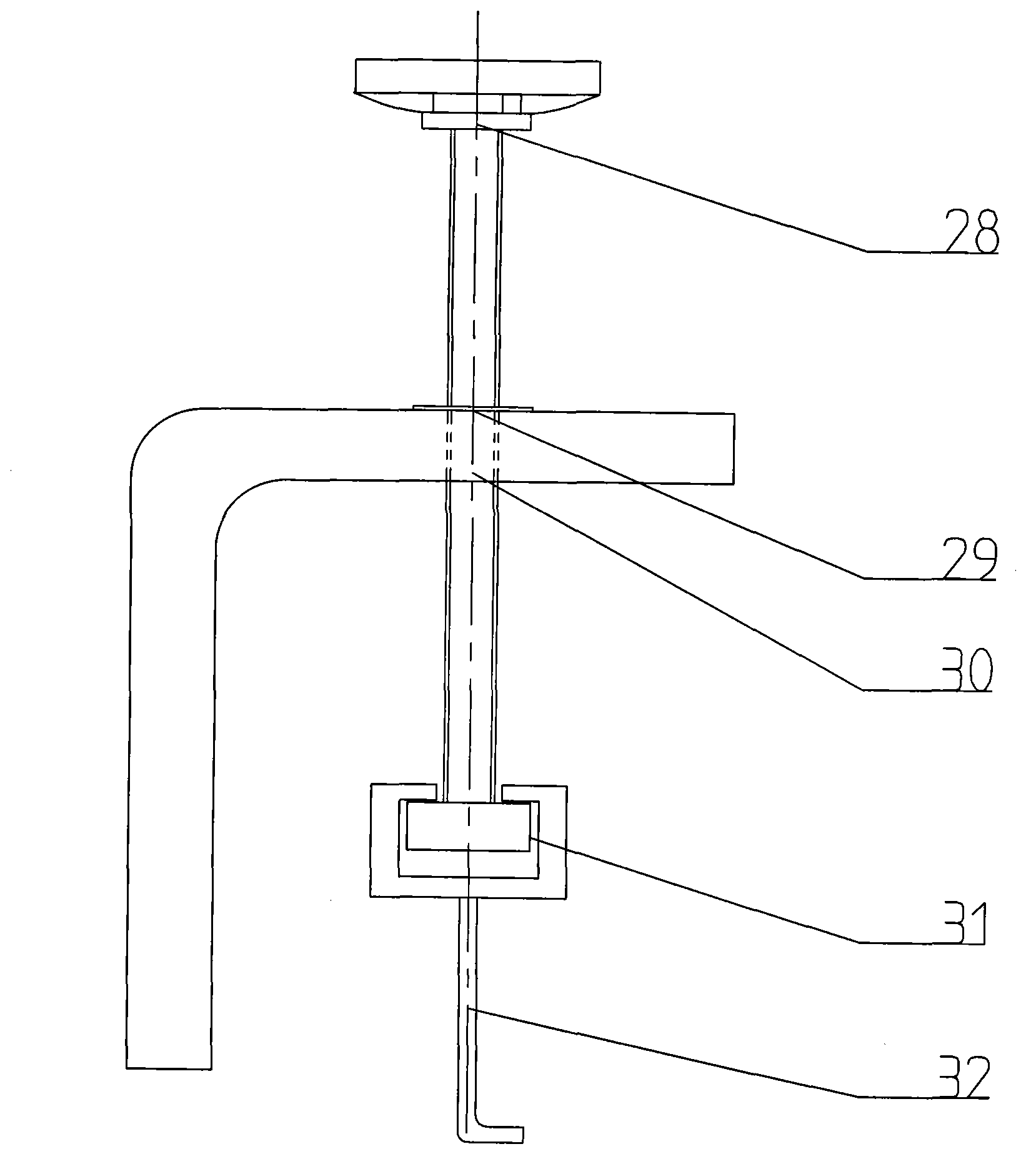

[0030] Please see attached figure 1, the specific method of the test is: according to the requirements of the two-phase flow test, prepare the particle size and concentration of the two-phase flow medium, start the two-phase flow circulation pump (12), ensure the uniformity of the two-phase flow medium in the mixing tank (9), prevent Sedimentary or uneven. The two-phase flow test pump (17) and the motor (20) are fixed on the test pump installation and fixing base (21), and the two-phase flow test pump (17) is started, and the test sucks the two-phase flow medium from the inside of the mixing tank (9) , enter the rubber bellows (6), flow through the flange (5), the two-phase flow medium flows along the pipeline to the observation mirror (14), and the flow inside the pipeline can be observed through the observation mirror (14). The pump inlet pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com