Surrounding rock deformation early-warning construction method for small-diameter tunnel full-section excavation

A surrounding rock deformation and full-section technology, applied in tunnels, mining devices, mining equipment, etc., can solve problems affecting the safety of tunnel construction, limited measurement conditions, and affecting engineers' judgment, so as to achieve reasonable utilization of project funds and measurement points The effect of accurate layout and reasonable risk judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

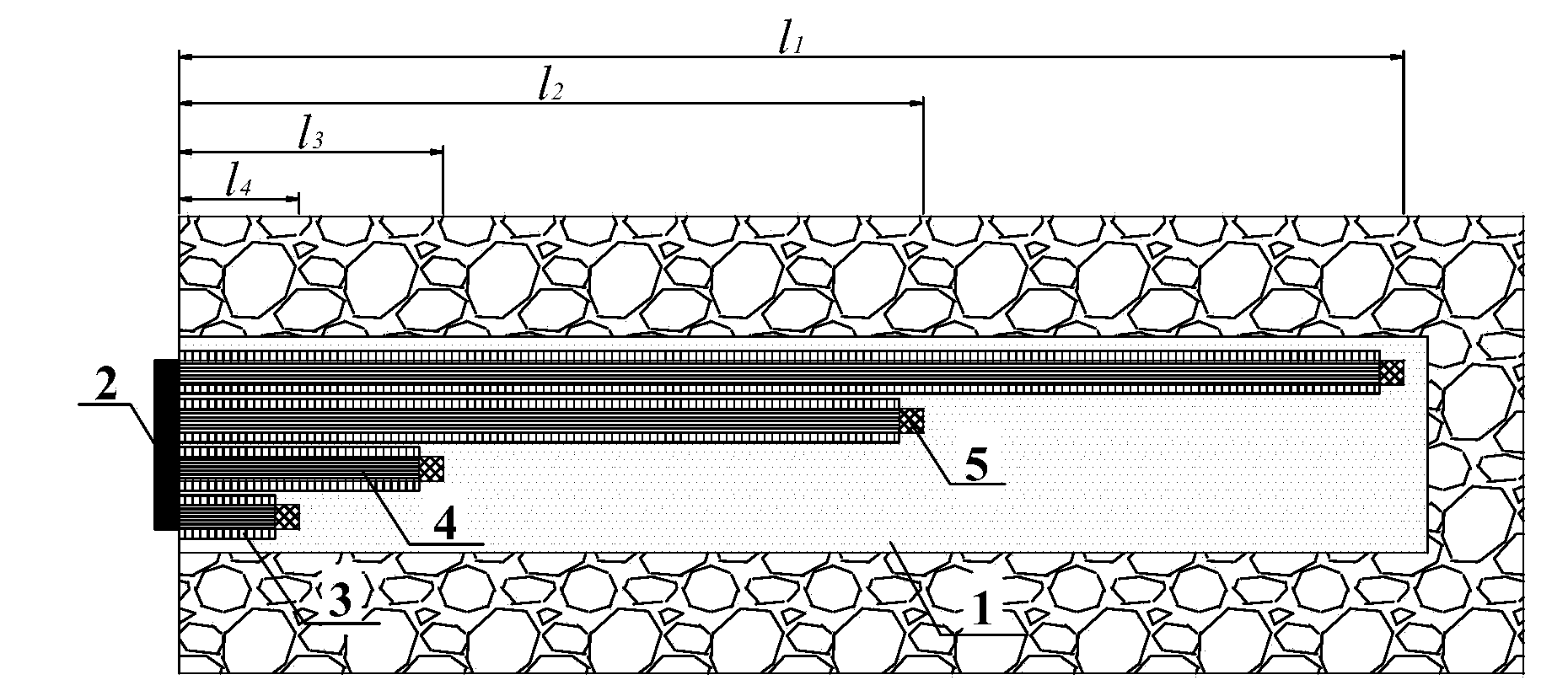

[0033] Taking the excavation of a tunnel project as an example, the tunnel is a circular tunnel with a diameter of 5m, a length of 2km, and a buried depth of 80m. The design time from the start of excavation to the completion of secondary lining pouring is 110 days. For guaranteeing construction safety, construction method of the present invention carries out according to the following steps:

[0034] Step 1, on-site geological survey:

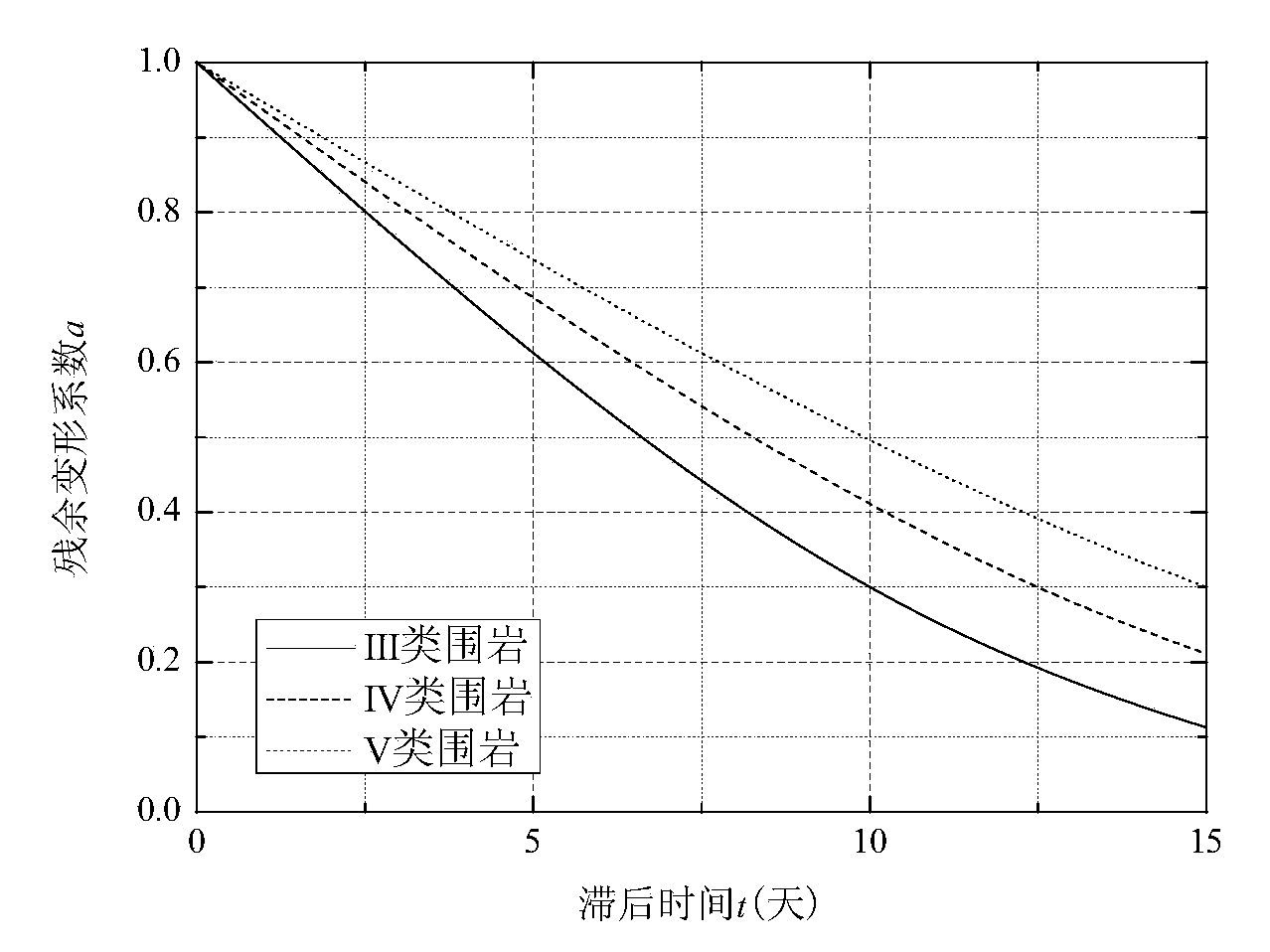

[0035] On-site coring was carried out for indoor tests. The integrity coefficient of the rock mass is 0.6 and the compressive strength is 70MPa. According to the "Engineering Rock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com