A hole-adjusting and pressure-changing downhole choke

A variable pressure well and choke technology, applied in the direction of production fluid, wellbore/well components, functional valve types, etc., can solve the problems that affect the normal production of natural gas wells, troublesome, easy to fail, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

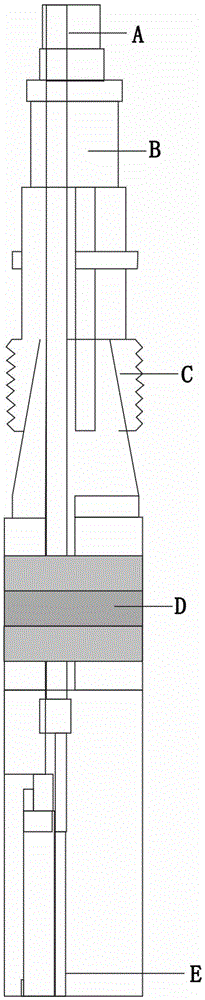

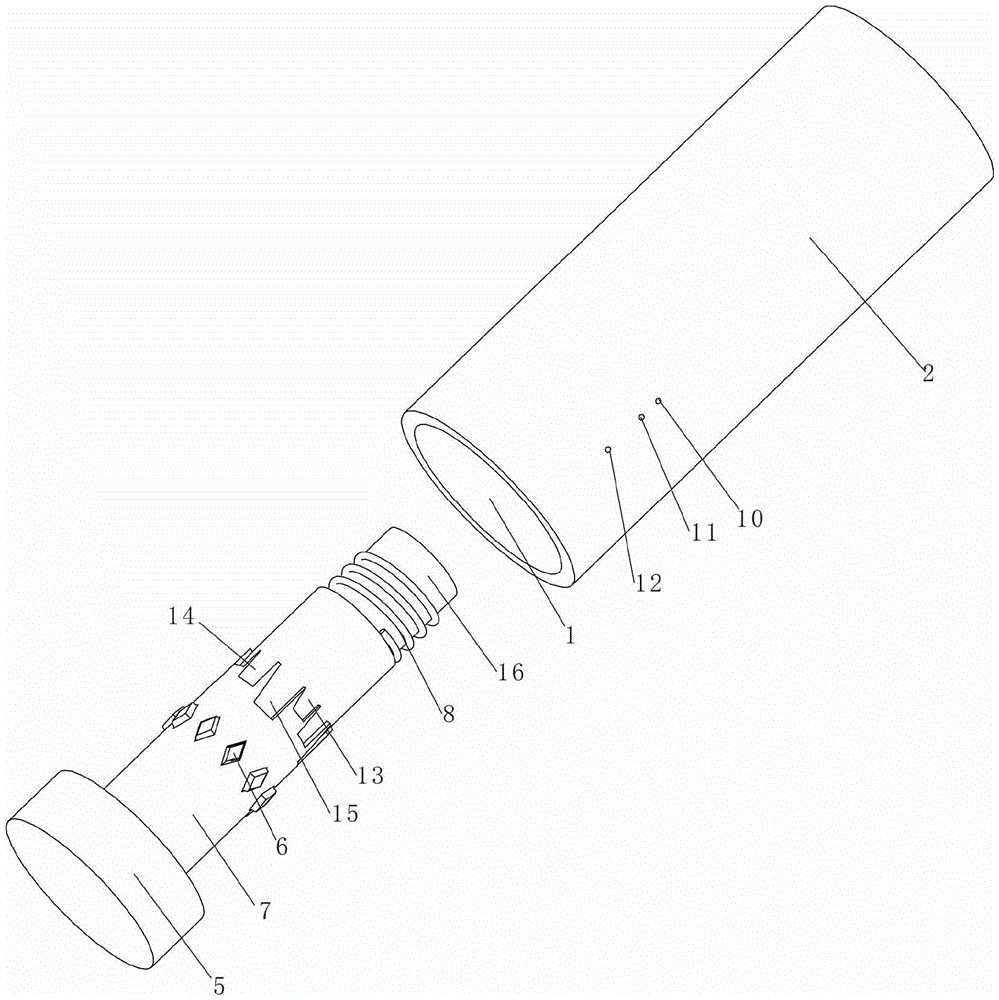

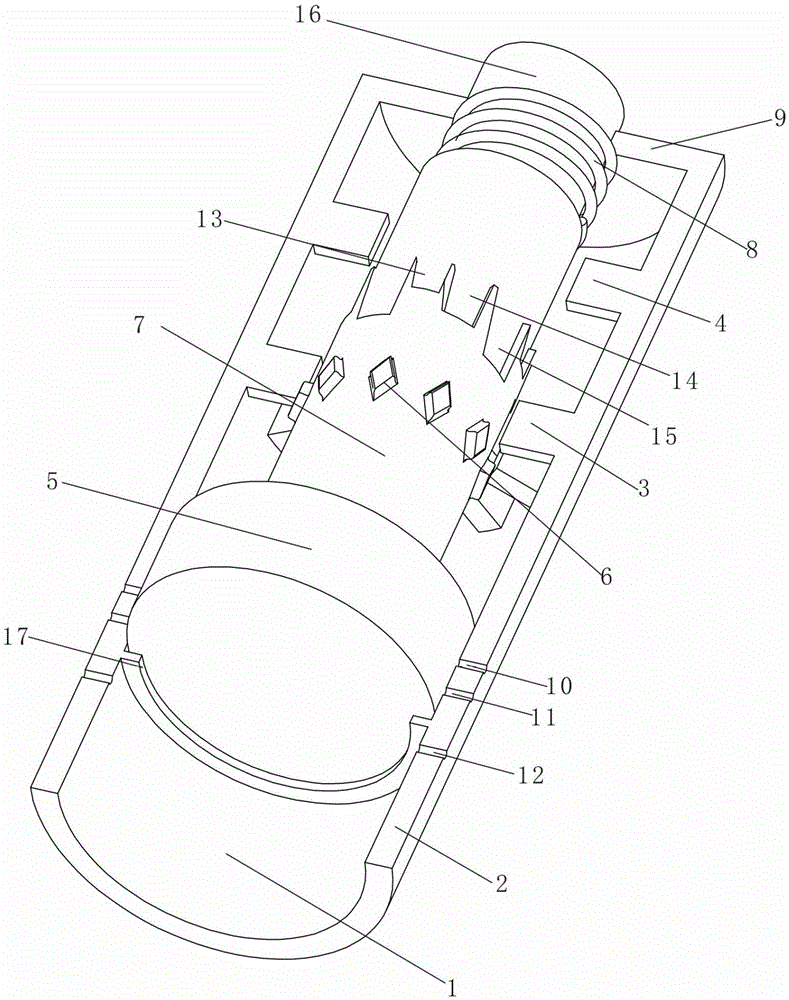

[0019] Depend on Figure 1 to Figure 5 As shown, this kind of downhole choke with hole adjustment and pressure transformation is composed of five parts: the unsealing mechanism A, the regulating valve B, the anchoring mechanism C, the sealing mechanism D and the air intake mechanism E. Among them, the improvement point lies in the regulating valve Part, other parts are prior art.

[0020] The regulating valve B has a valve body 2 and a valve core.

[0021] The valve body 2 is a hollow cylinder, and one end of the valve body 2 is connected with a regulating valve top cover 9 with a central through hole for the fixed shaft to pass through, while the other end of the valve body 2 is the central hole 1 . Between the central hole 1 and the regulating valve top cover 9, along the inner wall of the valve body, a circular bayonet 17, several cuboid regulating blocks 3 and several...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com