Protective cap for column base of transformer substation power distribution unit steel frame

A technology for power distribution devices and steel frame columns, which is applied in the field of substation infrastructure protection devices, can solve problems such as corrosion and on-site construction difficulties, achieve the effects of reducing workload, simplifying on-site installation procedures, and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

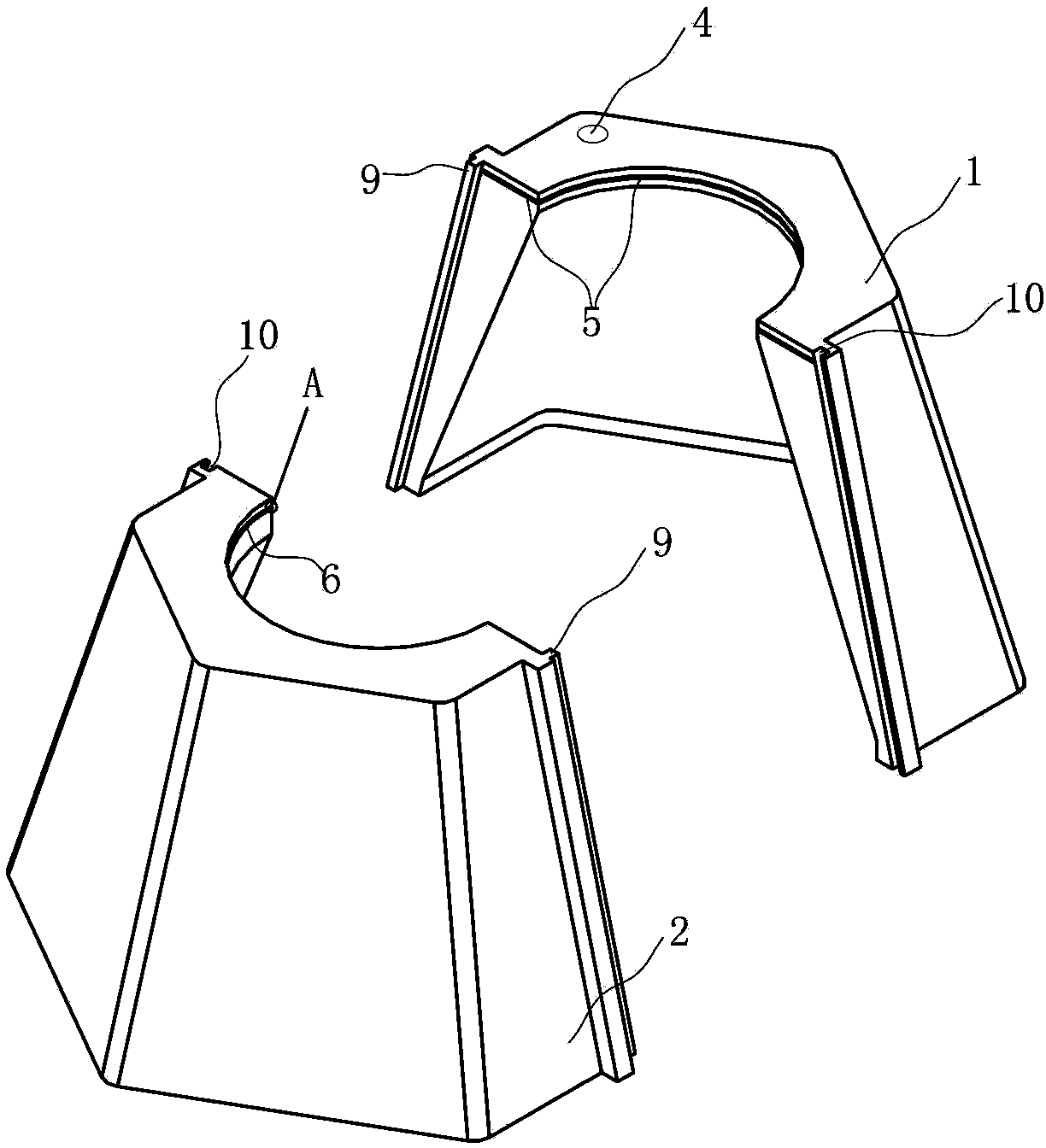

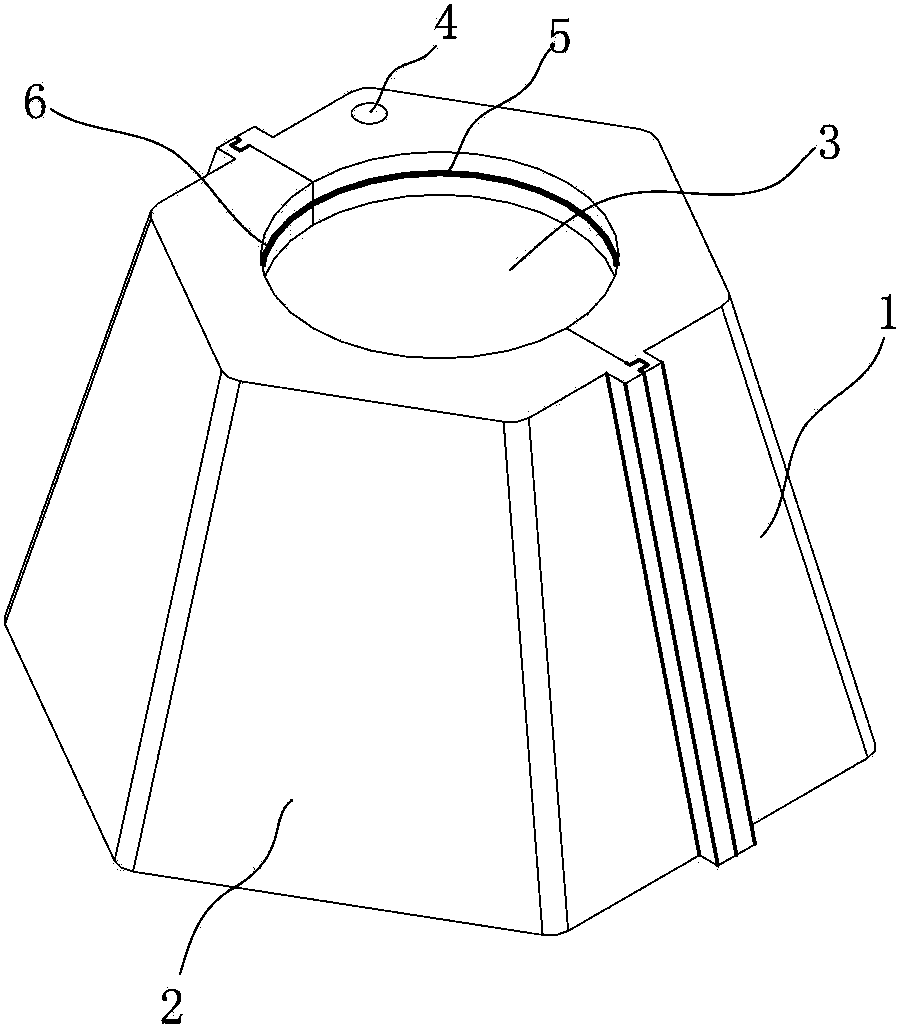

[0025] As shown in the figure, the protective cap of the steel frame column foot of the power distribution device of the substation, the plastic cap body is formed by two half cap bodies 1 and 2 left and right sealed butt joints, and the center of the upper end surface of the cap body forms a positioning hole 3 for sealing connection , the upper end face of each half cap body forms half described positioning hole, and the upper end face of one half cap body 1 wherein has a butter filling port 4 for injecting butter into the inner chamber of the cap body, the butter filling port 4 places are connected with bolts 13 for sealing. The bottom of the cap body is open, and the lower end surface is a plane. The cap is in the shape of a platform with a small top and a large bottom.

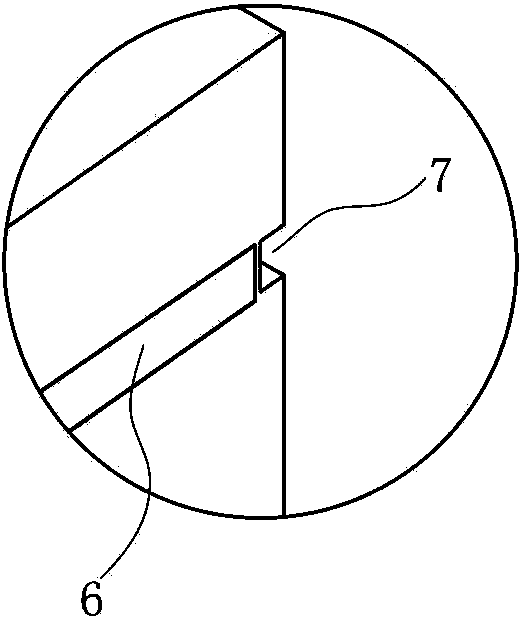

[0026] A continuous transversely arranged rubber waterstop 5 is embedded on the two butt joint surfaces of the half cap body 1 top and the hole wall of the half positioning hole. A continuous horizontall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com