Apiculatus yeast with low-yielding ethyl carbamate and application

A technology of urethane and wine yeast is applied in the biological field to achieve the effects of high bacterial growth and alcohol production rate, high social and economic benefits, and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: Screening of yeast CY5 with low production of ethyl carbamate

[0020] ⒈ Test the gas production performance of yeast: use the Dunbar tube fermentation method, add 10ml of 10oBrix wort into the test tube, sterilize and cool it, add the test yeast, ferment at 25°C for 48 hours, select the gas production equal to the volume of the Dunbar tube strains.

[0021] 2. Alcohol-producing ability test of yeast: Cabernet Sauvignon grape juice in Changli area was used as raw material, and the total sugar content of the grape juice was 210g / L. After culturing at 28°C for 6 days, select strains with a wine alcohol content above 11% (V / V) and balanced aroma after fermentation.

[0022] 3. Alcohol tolerance and SO 2 Tolerance test: Add 10ml of 13oBrix wort into the test tube by using the Dunbar tube fermentation method, add absolute ethanol (8%, 10%, 12%, 14%, 16%, 18%) and SO 2 (50mg / L, 100mg / L, 150mg / L, 200mg / L), inoculate the yeast strain to be tested, and culture it s...

Embodiment 2

[0025] Example 2: Small-scale winemaking comparison of low-urethane-producing yeasts and commercial strains in Cabernet Sauvignon grape juice

[0026] Put 2L of Cabernet Sauvignon grape juice in 2 2.5L jars (physical and chemical indicators: reducing sugar 263.1g / L, total acid 8.1g / L, pH 3.80, add total SO 2 About 60mg / L), adding low-aminoethyl ester yeast and commercial yeast D21 (French Laman Group) used by wine companies to make the final concentration reach 1×10 6 CFU / mL, produced according to the standard process of dry red wine. After the fermentation, the clarified dry red wine was taken, and the content of ethyl carbamate and aroma components and content were determined by sampling.

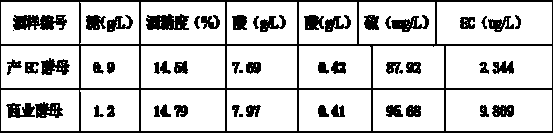

[0027] Table 1 Physical and chemical indicators of wine produced by two yeast strains

[0028]

[0029] The results are as follows: compared with the commercial strains, the residual sugar measured after the fermentation was less than 4g / L, and the alcohol content was not significant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com