Method for extracting chamomile extract by using countercurrent tube type ultrasonic device

A technology of chamomile flowers and ultrasonic equipment, which is applied in the direction of producing fat, essential oils/spices, etc., can solve problems such as inability to realize extraction and utilization, and achieve the effects of low organic solvent residues, maximized production efficiency, and reduced costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

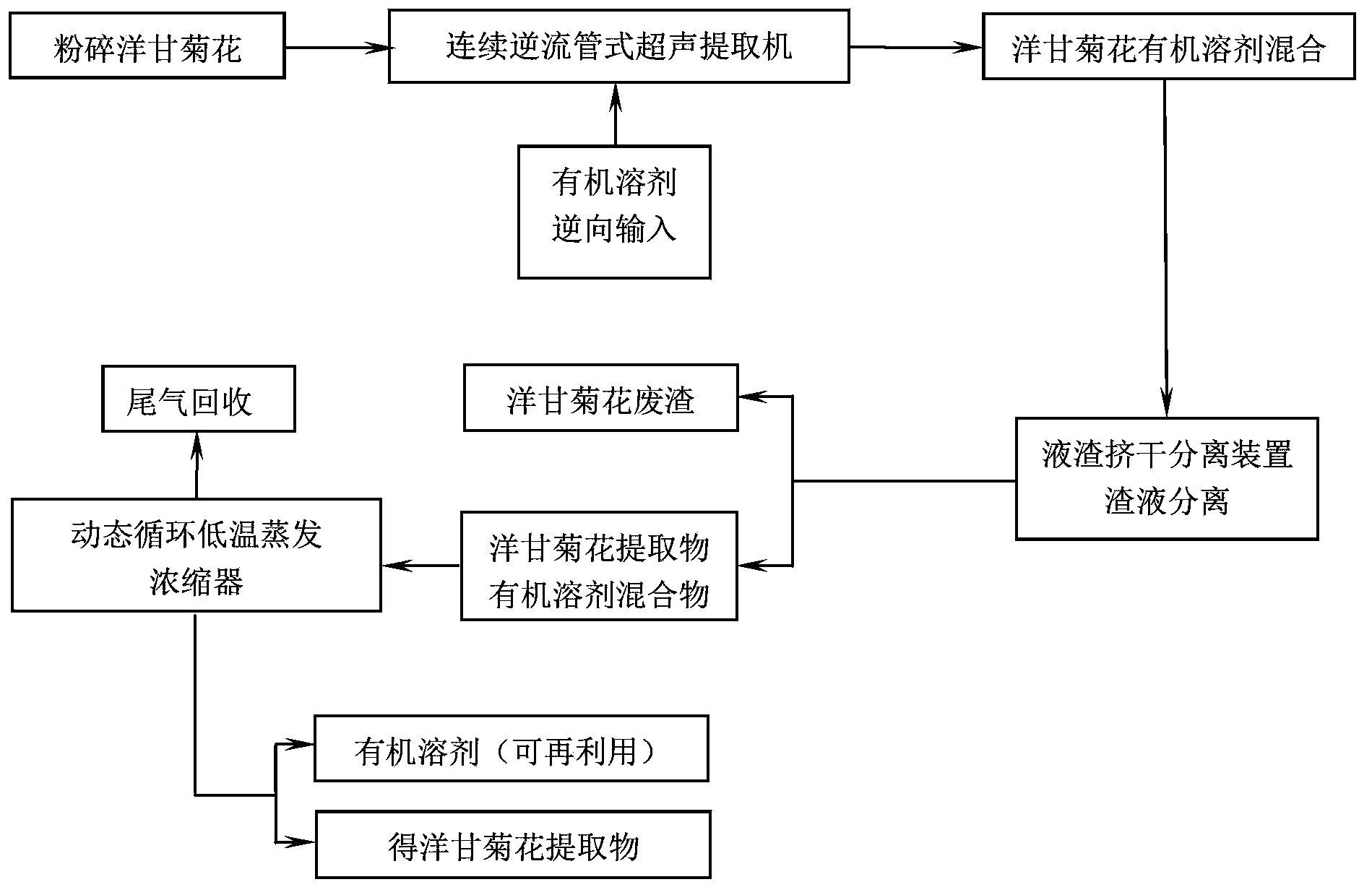

Method used

Image

Examples

preparation approach 1

[0019] Take 100kg of chamomile flowers that have been crushed through a 20-mesh sieve, and input them into a continuous countercurrent tubular ultrasonic extractor that meets the national standard of JB / T20126-2009 at a speed of 100kg / h, and input them into Xinjiang Jiepule Biotechnology Co., Ltd. at a flow rate of 800L / h. The produced organic solvent ethanol (95%) was extracted for 45 minutes while maintaining the temperature of the ultrasonic extraction tube at 40°C to obtain the chamomile ethanol mixture; after the mixture was input into the extraction liquid residue squeezing separation device, the residue material and the extraction mixture were separated; The extracted mixture is input into a dynamic circulating low-temperature and reduced-pressure (-0.06MPa) evaporation concentrator, and the temperature is maintained at 45°C. The organic solvent ethanol is evaporated and recovered for reuse. Collect 12 kg of the remaining extract, which is the chamomile flower extract, wi...

preparation approach 2

[0021] Take 100kg of chamomile flowers that have been crushed through a 20-mesh sieve, and input at a speed of 100kg / h into a continuous countercurrent tubular ultrasonic extractor that meets the national standard of JB / T20126-2009, and input the reverse flow rate of 1000L / h into Tianjin Fuyu Fine Chemical Co., Ltd. The organic solvent ethyl acetate is extracted for 40 minutes at a temperature of 45°C in the ultrasonic extraction tube to obtain the ethyl acetate mixture of chamomile flowers; after the mixture is fed into the extraction liquid residue squeezing separation device, the residue and the extraction mixture are separated; the extraction mixture Enter the dynamic cycle low-temperature decompression (-0.06MPa) evaporation concentrator, keep the temperature at 40℃, evaporate and reuse the organic solvent ethyl acetate, collect the remaining extract 10kg, which is the chamomile flower extract, the yield is 10%.

[0022] The application effect of the extract obtained by this ...

example 1

[0024] The addition of chamomile handmade soap:

[0025] In the production of handmade soap, after the saponification reaction process is completed, add 0.5-3% of chamomile extract (kg / kg) when the temperature of the saponification solution is maintained at 40-80℃, and stir it evenly at constant temperature and inject it into a molding mold to cool, divide, and package chamomile hand-made soap. The chamomile extract is used in the production of handmade soaps, instead of the use of chemical flavors and pigments in ordinary soaps. After use, the body surface can retain fragrance continuously, which can play a role in whitening, moisturizing, moisturizing, antibacterial, anti-allergic, etc. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com