Preparation method of 3-cyanopyridine oxynitride

A technology of cyanopyridine nitrogen oxide and cyanopyridine, which is applied in the field of preparation of chemical intermediates, can solve the problems of difficulty in improving enterprise benefits, high production costs, poor market competitiveness, etc., and achieves fast reaction speed and increased affinity. The effect of shortening electric capacity and reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Example 1, take 500kg of barreled 3-cyanopyridine, put it into hot water at 70-80°C and slowly melt it, then add it to the enamel reaction kettle, then add 10kg of concentrated sulfuric acid and 8kg of molybdenum oxide into the reaction kettle, and stir , slowly raise the temperature to 65°C, start to add hydrogen peroxide dropwise, and control the dropping rate to 200kg / h. When the pyridine content is ≤1.0%, stop the heat preservation; adjust the reaction liquid with potassium carbonate to pH 9.5-10.5, crystallize, cool down to below 5°C, centrifuge, take the crystal and dry it at 80-90°C to obtain 3-cyano Pyridine nitrogen oxide; after testing, content: ≥98.0%, moisture: ≤1.0%, 3-cyanopyridine: ≤1.0%, meeting the quality requirements.

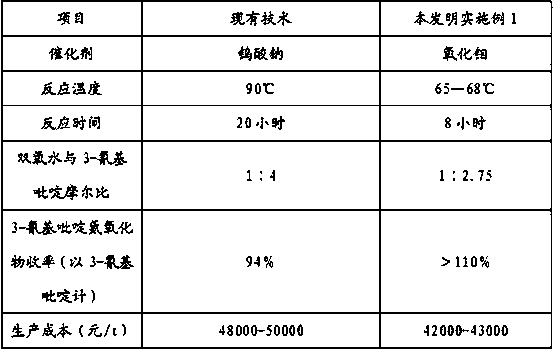

[0011] The technical and economic indicators of the 3-cyanopyridine nitrogen oxides prepared by embodiment 1 and the prior art are shown in the table below:

[0012]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com