Machining device for seal ring annular seats of pressure steam sterilizers

A technology of pressure steam and processing equipment, which is applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of increased manufacturing cost, long processing time, and high cost, and achieve reduced production cost, short cutting time, and fast processing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

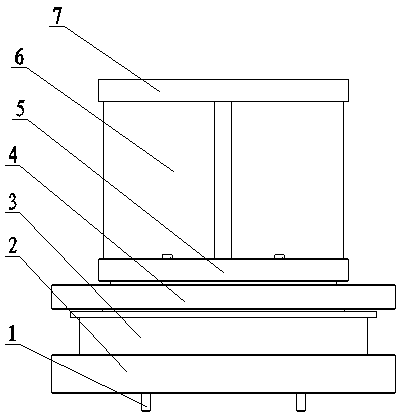

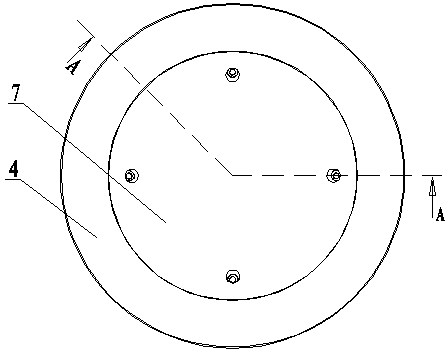

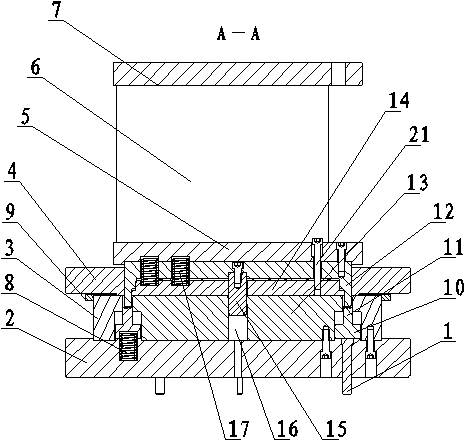

[0030] A pressure steam sterilizer seal ring seat processing device, including a punch and a die, the structure of the die is: a die seat 2 is provided, and the die seat 2 is provided with an annular outer die 3, the outer die 3. The inner die base 2 is provided with a circular inner die 13 concentric with the outer die 3. The upper sides of the outer die and the inner die 13 are on the same horizontal plane. The center of the inner die 13 is provided with a pair of dies. The die hole 16, the inner die 13 and the outer die 3 are provided with an annular plastic groove, that is, the diameter of the inner die is smaller than the inner diameter of the outer die, and there is an annular ring concentric with the inner die and the outer die between the two. notch. The inner die and the outer die below the shaping groove are provided with an annular chute matching the shaping groove, the chute and the shaping groove are concentric, the inner diameter of the chute is smaller than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com