Method for comprehensively treating and utilizing household garbage incineration slag

A domestic waste incineration and comprehensive treatment technology, which is applied in the field of comprehensive treatment and utilization of domestic waste incineration slag, can solve problems such as air pollution, hidden dangers of construction projects, and environmental pollution, and achieve the effects of eliminating dust, ensuring quality, and reducing metal content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

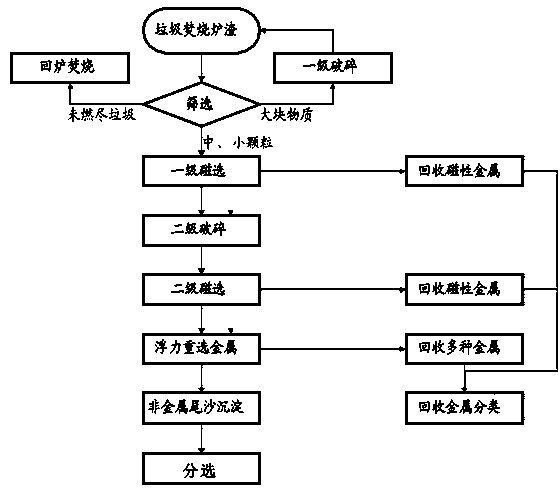

[0022] Such as figure 1 As shown, the method for the comprehensive treatment and utilization of domestic waste incineration slag includes the following steps:

[0023] 1) Screening and primary crushing: The slag produced by incineration has mixed components. In order to prevent damage to the assembly line equipment, primary screening and primary crushing of the slag are required. The slag is sent into the hopper by a forklift, and then transported into the screening roller cage feed port through the conveyor belt. The rolling cage is a trumpet-shaped screen that can rotate continuously. The slag enters from the small opening of the trumpet-shaped rolling cage. After passing through the rotating rolling cage, the slag particles with a diameter of less than 100mm flow out through the mesh on the side of the rolling cage and enter the next process; while the larger slag blocks, stones, and concrete blocks And large pieces of metal flow out through the big mouth end of the trump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com