Small super-speed horizontal helical centrifugal machine

An ultra-high-speed decanter centrifuge, small-scale technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problems of low separation factor, large liquid content of materials, complex slag discharge device, etc., and achieve processing capacity Large, solve the separation problem, the effect of small solid liquid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further describe the present invention, the specific implementation manner of the present invention will be further elaborated below in conjunction with the accompanying drawings and examples.

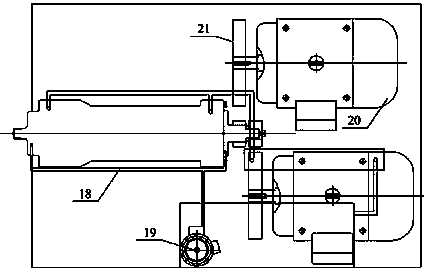

[0019] Such as figure 1 , figure 2 The small ultra-high-speed decanter centrifuge shown includes a support foot 1, a platform 3 is arranged on the support foot 1, and a shell cylinder 7 is arranged on the platform 3, wherein, positioning steps are arranged at both ends of the shell cylinder 7, and two The positioning steps at the end are respectively provided with a front bearing seat 5 and a rear bearing seat 12, which greatly reduces the volume of the centrifuge and simplifies the structure of the centrifuge. The bearing end cover on the front bearing seat 5 is provided with a feed pipe 4, and the side of the feed pipe 4 is provided with a liquid level adjustment plate 6 and a liquid retaining ring 8, and a drum 10 is provided on the rear bearing seat 5, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com