Method for preparing cellulose-based macroporous gel compound Cu2O visible-light-driven photocatalyst

A cellulose-based, cuprous oxide technology, used in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as unsatisfactory removal of organic pollutants , to achieve good application prospects, increase load fastness, and improve removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

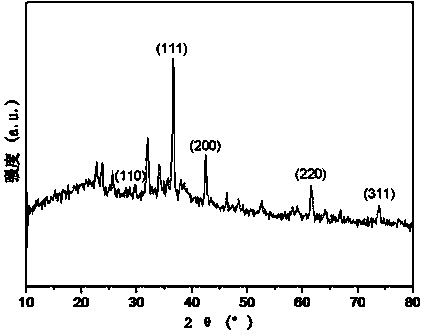

Image

Examples

preparation example Construction

[0021] (1) Preparation of cellulose-based macroporous gel: Dissolve cellulose in a mixed solution containing 7wt% NaOH and 12wt% urea to obtain a transparent cellulose solution with a cellulose mass fraction of 3.3%; ammonium persulfate for 10 minutes, then sequentially add cross-linking agent N,N'-methylenebisacrylamide, acrylic acid and acrylamide monomer, polymerize at 0℃~-18℃ for 12 hours, the product is washed with water and extruded After granulation, freeze-dry to obtain -OH, -COOH, -NH 2 Cellulose-based macroporous gel with multiple active groups, the mass ratio of cellulose, ammonium persulfate, N,N'-methylenebisacrylamide, acrylic acid, and acrylamide in the cellulose-based macroporous gel is 1 :0.1:(0.03~0.05):(1~4):(0~4);

[0022] (2) Preparation of cellulose-based macroporous gel composite cuprous oxide visible light catalyst: immerse 0.1-0.5 g of cellulose-based macroporous gel obtained in step (1) into 30 mL of 0.1-1.0 mol / L containing Cu 2+ Add 30mL NaOH aqu...

Embodiment 1

[0029] (1) Preparation of cellulose-based macroporous gel: waste flax yarn was washed and dried, and then pulverized as cellulose raw material. 1 g of the above-mentioned cellulose was dissolved in 30 mL of a solution containing 7 wt% NaOH and 12 wt% urea to obtain a transparent cellulose solution with a cellulose mass fraction of 3.3%. Then add 0.1 g of initiator ammonium persulfate at room temperature for 10 min, then add 0.03 g of cross-linking agent N,N'-methylenebisacrylamide and 2 g of acrylic acid in sequence, polymerize at 0°C for 12 h, and the product is washed with water and extruded After granulation, freeze-dry to obtain a spherical cellulose-based macroporous gel with a pore size of 10 μm.

[0030] (2) Preparation of cellulose-based macroporous gel composite cuprous oxide photocatalyst: immerse 0.2 g of cellulose-based macroporous gel into 30 mL of CuSO with a concentration of 0.5 mol / L 4Add 30mL NaOH aqueous solution with a concentration of 2.0 mol / L, then add 4...

Embodiment 2

[0033] (1) Preparation of cellulose-based macroporous gel: Take 1 g of pulp pulp as the cellulose raw material, dissolve it in 30 mL of a solution containing 7 wt% NaOH and 12 wt% urea, and obtain a transparent gel with a mass fraction of 3.3% cellulose. Cellulose solution. Then 0.1 g of initiator ammonium persulfate was initiated at room temperature for 10 min, 0.05 g of cross-linking agent N,N'-methylenebisacrylamide, 4 g of acrylic acid and 1 g of acrylamide were added successively, and polymerized at -18 °C for 12 h. The product was washed with water and freeze-dried in a 24-well plate to obtain a columnar cellulose-based macroporous gel with a pore size of 200 μm.

[0034] (2) Preparation of cellulose-based macroporous gel composite cuprous oxide photocatalyst: 0.1 g of cellulose-based macroporous gel was immersed in 30 mL of Cu(Ac) with a concentration of 0.1 mol / L 2 Add 30 mL of NaOH aqueous solution with a concentration of 3.0 mol / L, then dropwise add 40 mL of glucose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com