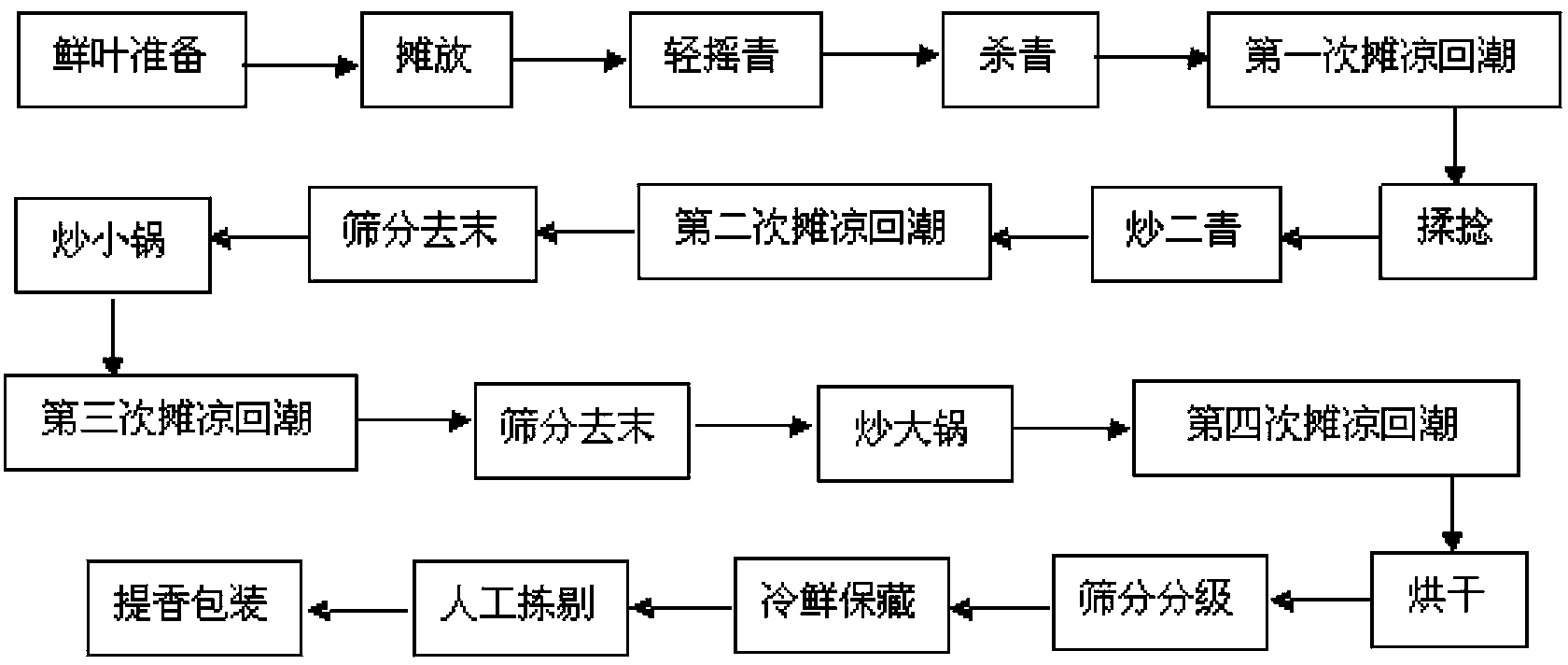

Particle tea processing process

A processing technology and technology of granule tea, which is applied in the field of granule tea processing technology, can solve the problems of cable-shaped tea leaves with thick shape, easily broken packaging, and affecting the yield of finished products, so as to improve market competitiveness, facilitate storage and transportation, and facilitate The effect of vacuum packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Spread 25kg of fresh leaves in bamboo strips for 1 hour, with a thickness of 3cm. The color of the fresh leaves changes from vivid emerald green to dark green, the luster of the leaves basically disappears, the smell of green grass is reduced, and the leaves become soft;

[0024] (2) Gently shake the green: Shake the green for 2 minutes for the first time, spread the leaf thickness to 6cm, and let it rest for 1 hour. At this time, the leaf tip softens, the leaf surface flattens, the luster disappears, the dark green color of the leaf deepens, and the green color of the leaf edge turns light. The green gas fades, with a slight green fragrance, and then shake the green for the second time for 5 minutes, the thickness of the leaves is 8cm, and the standing time is 2h. Flattening, mesophyll green turns light, green gas fades, flower fragrance is obvious;

[0025] (3) Place the tea leaves in a 6CST-60 roller degreening machine for degreening. The set temperature of the d...

Embodiment 2

[0038] Put 25kg of fresh leaves in bamboo rafts and spread them for 80 minutes, with a thickness of 3.5cm; shake the green leaves twice, the first shake for 2.5 minutes, spread the leaves to a thickness of 6cm, stand for 70 minutes, shake the green leaves for the second time for 6 minutes, The leaf thickness is 8cm, and the standing time is 140min; the setting temperature of the fixing machine is 235°C, and the weight loss rate of the tea leaves is 43%; Knead under air pressure for 17 minutes; stir-fry Erqing with a drum frying machine for 14 minutes, throw in 14.2kg of leaves, tea temperature is 71°C, pot temperature is 237°C; spread the tea leaves to cool for a second time for 25 minutes, and use a fine sieve to remove the tea powder; stir-fry In a small pot, put 4.3kg of tea leaves into the Quhao frying and drying machine. The temperature of the frying and drying machine is set at 140°C, and the temperature of the tea leaves is 71°C. Use a large swing to quickly throw and fr...

Embodiment 3

[0040] Put 25kg of fresh leaves in bamboo rafts and spread them for 100 minutes, with a thickness of 3.3cm; shake the green leaves twice, shake the green leaves for the first time for 2 minutes, spread the leaves to a thickness of 7cm, let them stand for 100 minutes, shake the green leaves for the second time for 6 minutes, and spread them The leaf thickness is 9cm, and the standing time is 145min; the setting temperature of the greening machine is 245°C, and the weight loss rate of tea leaves is 53%; Press and knead for 19 minutes; stir-fry Erqing with a drum frying machine for 10 minutes, the amount of leaves cast is 11.7kg, the temperature of the tea leaves is 72°C, and the temperature of the pot is 236°C; the tea leaves are cooled for the second time for 26 minutes, and the tea powder is sieved with a fine sieve; Put 3.5kg of tea leaves into the Quhao frying and drying machine, set the temperature of the frying and drying machine at 140°C, and the temperature of the tea lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com