Ink composition for continuous deflected jet printing

An ink composition, inkjet printing technology, applied in the directions of inks, applications, household appliances, etc., can solve the problems of reduced salt solubility, increased risk of precipitation or crystallization, etc., to achieve the effect of improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

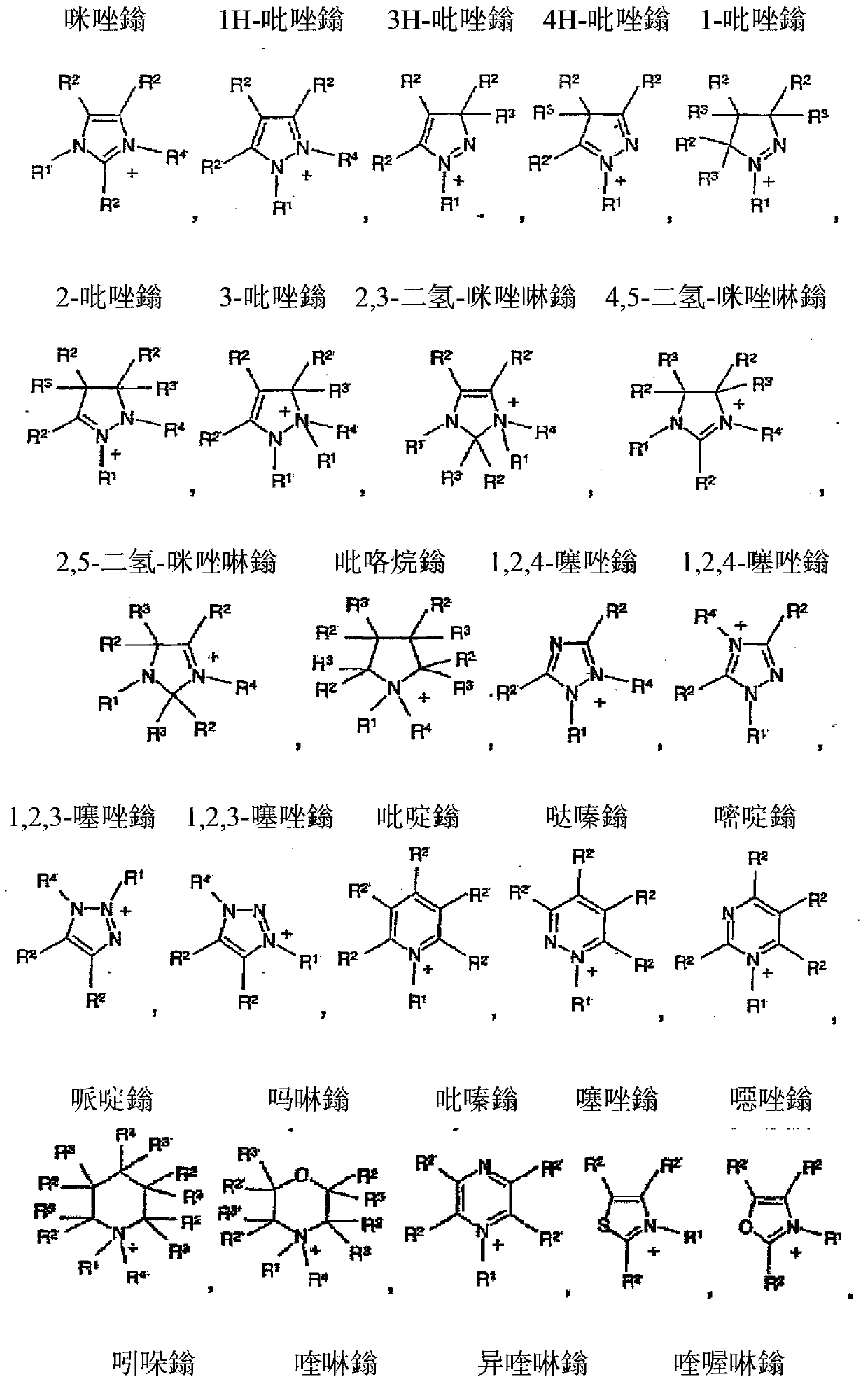

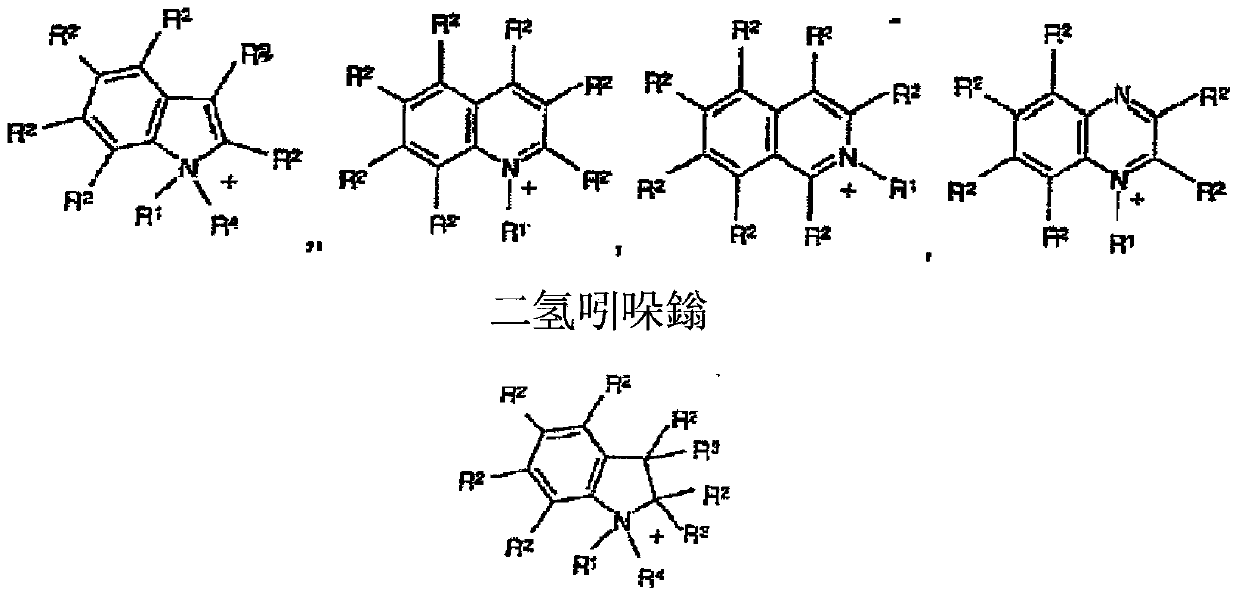

Method used

Image

Examples

Embodiment

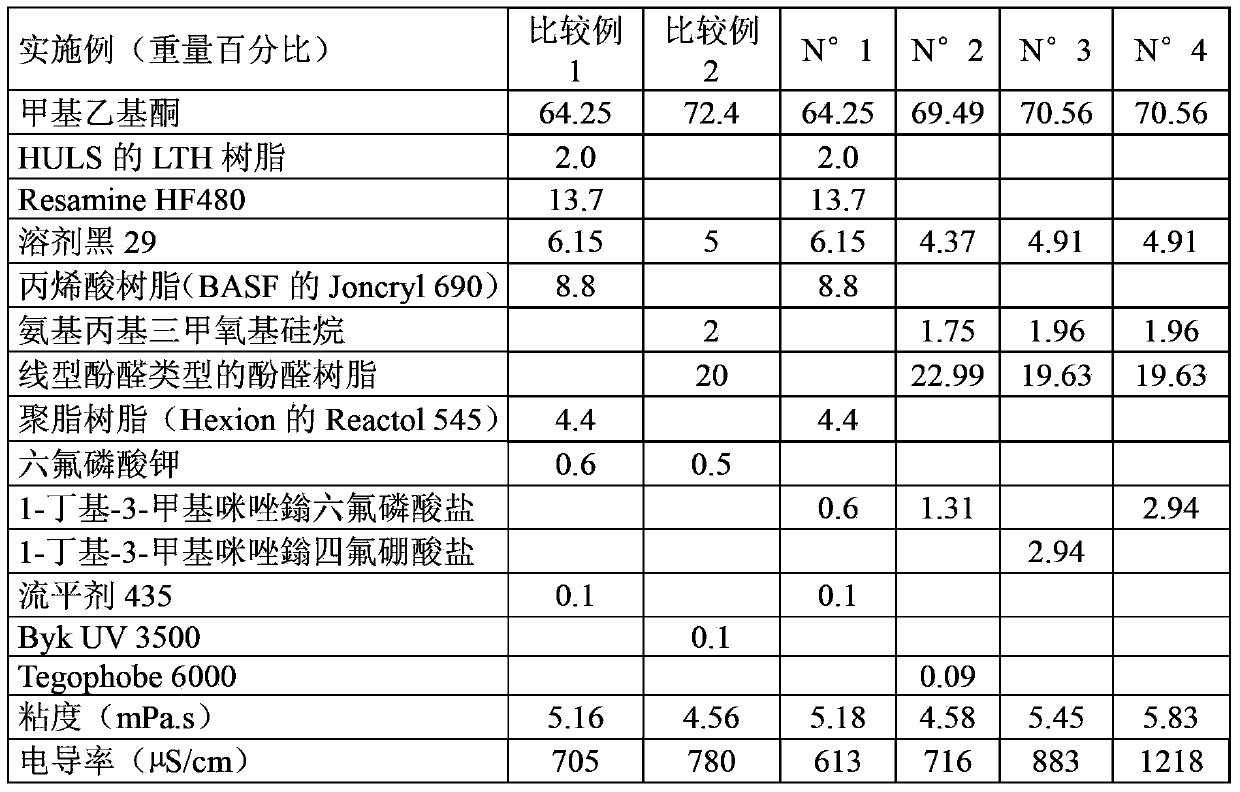

[0204] The following ink compositions according to the invention were prepared by mixing the products given in Table I below in the proportions indicated. The viscosity and conductivity of the inks obtained are also given below.

[0205] Viscosity was measured using a low shear 30 coaxial cylinder viscometer from Contraves (Switzerland) at 20 °C and conductivity at room temperature, typically 20 °C.

[0206] Table I

[0207]

[0208] The ink compositions of the present invention prepared according to Examples 1 to 4 and those of Comparative Examples 1 and 2 were filtered on a filter having a pore size of 1 μm to give an ink capable of inkjet by jetting.

[0209] exist The inks thus prepared were tested on a 9040 model continuous deflection inkjet printing printer.

[0210] The marks, prints obtained using the inks in Examples 1 to 4 and Comparative Examples 1 and 2 were all of high quality and their resistance to friction of water on glass was excellent.

[0211] How...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com